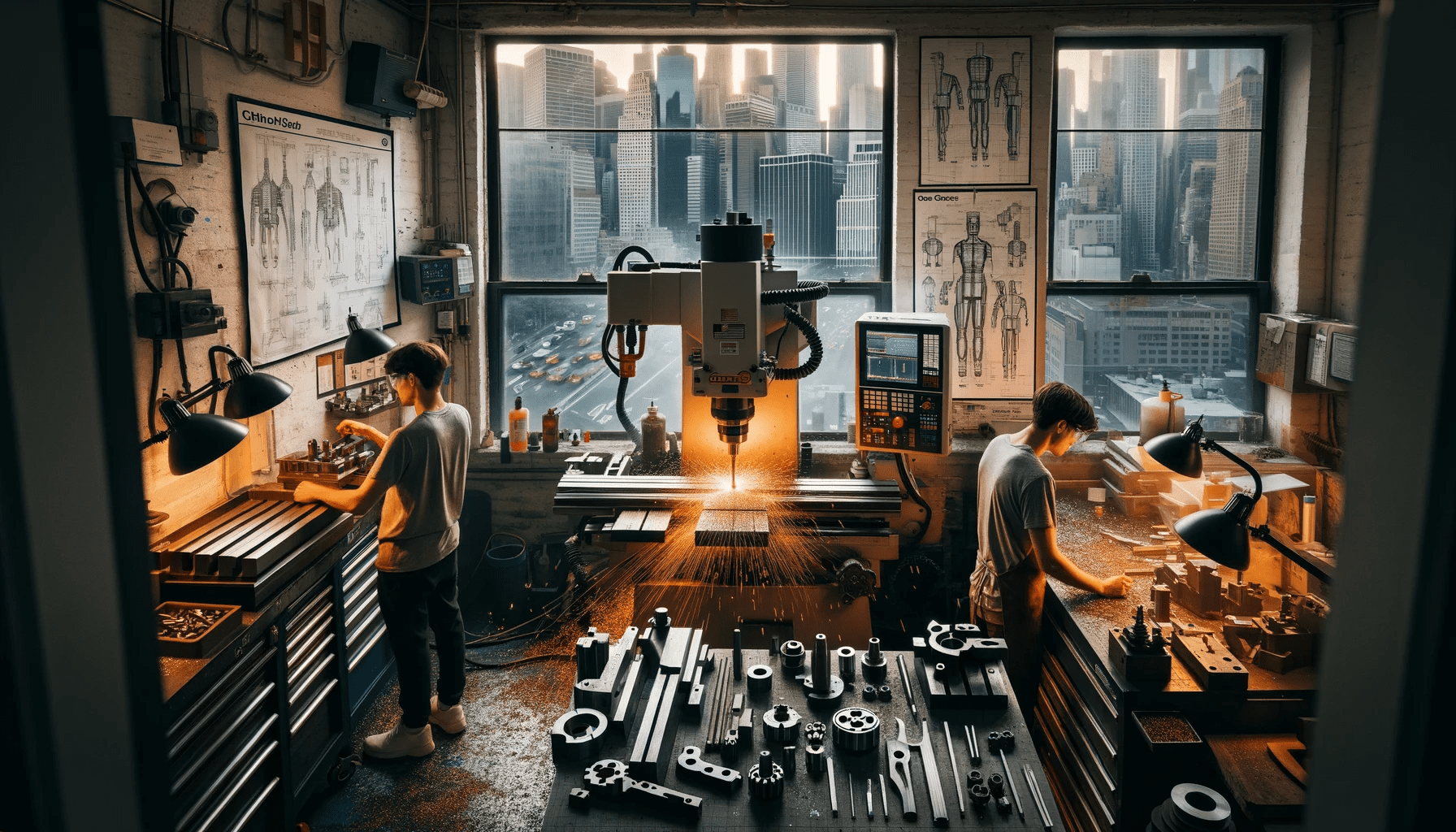

Precision CNC machine shop services in New York offer high-quality, custom-manufactured parts and components for various industries. These services utilize computer-controlled machines to produce intricate and complex designs with exceptional accuracy, often achieving tolerances as tight as ±0.0001 inches. Experienced CNC machinists in New York operate advanced equipment, including 5-axis CNC machines, to work with a wide range of materials such as metals, plastics, and composites.

The capabilities of these shops extend to CNC milling, turning, wire EDM, and precision deburring, catering to diverse client needs across sectors like aerospace, medical, military, and manufacturing. New York’s CNC machine shops pride themselves on their ability to handle challenging projects, from prototyping to large-scale production runs, ensuring consistent quality and quick turnaround times. Many of these shops offer end-to-end solutions, including design assistance, material selection, and post-processing services, making them valuable partners for businesses seeking precision-engineered parts in New York.

Understanding the Need for Precision CNC Services in New York

New York is an industrial powerhouse, home to a multitude of industries such as aerospace, automotive, electronics, and healthcare, which have a high demand for precision parts and components. These sectors require a high degree of accuracy and consistency in their manufacturing processes, which can only be achieved through Precision CNC (Computer Numerical Control) services. The need for these services is not just limited to these industries; even sectors like construction, agriculture and consumer goods require precision-machined components.

The high demand for precision parts is due to the critical role they play in the function and performance of various machinery and equipment. These parts are integral to the successful operation of engines, robotics, medical devices and more. Hence, there is a need for a reliable and consistent provider of Precision CNC services in New York to cater to these requirements.

Furthermore, the need for Precision CNC services is driven by the push towards automation and digitalization in New York’s manufacturing sector. In an era where efficiency and accuracy are paramount, the use of CNC machines has become an industry standard. The fact that these machines can produce a large number of complex parts with minimal human intervention, while maintaining a high level of accuracy, is a testament to their value.

Overview of Precision CNC Machine Shop Services

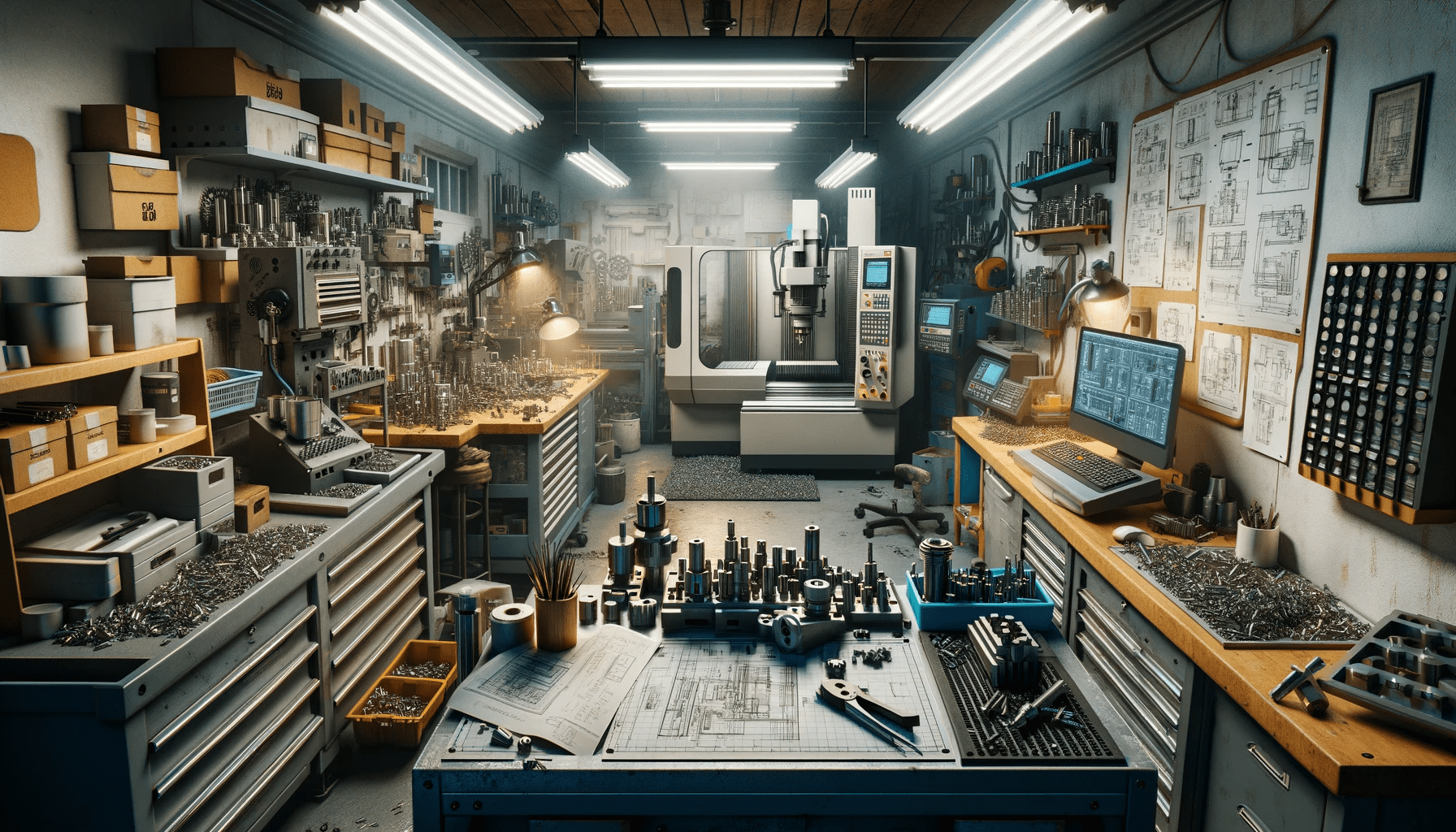

Precision CNC machine shop services involve the use of computer-controlled machines to manufacture parts and components with high accuracy and precision. These services typically include milling, turning, drilling, and grinding processes, which are carried out using advanced CNC machines.

The CNC machines function based on a set of instructions programmed into their system, which allows them to carry out complex operations with a high degree of precision. This enables the production of components with intricate designs and exact specifications, which is a crucial requirement in many industries.

Besides the primary machining processes, precision CNC machine shop services also include secondary operations such as heat treating, plating, and finishing. These operations are necessary to ensure that the manufactured parts meet the required standards of durability, corrosion resistance, and surface finish.

Key Characteristics of High Quality CNC Machine Shops

A high-quality CNC machine shop is characterized by several key traits. First and foremost, it should possess advanced CNC machines capable of performing a wide range of machining processes with high precision. These machines must be regularly maintained and updated to ensure their performance and reliability.

Secondly, a top-notch CNC machine shop should employ skilled and experienced machinists who are well-versed in operating CNC machines and creating precise programming instructions for them. These professionals should also be adept at inspecting and verifying the quality of the produced components.

Lastly, a high-quality CNC machine shop should adhere to stringent quality control measures. This includes rigorous inspection procedures and the use of advanced measurement tools to ensure that the manufactured parts meet the specified tolerances and standards.

The Role of Precision in CNC Machining Processes

Precision plays a critical role in CNC machining processes. It is the key factor that determines the accuracy and consistency of the manufactured parts. With high precision, CNC machines can produce components that perfectly match the design specifications, thereby ensuring their functionality and performance.

It also impacts the overall efficiency of the production process. By minimizing errors and rework, it allows for faster production times and lower costs. In industries where a small discrepancy can lead to significant problems, such as aerospace and healthcare, the importance of precision cannot be overstated.

Precision in CNC machining contributes to the durability and longevity of the manufactured parts. By producing components with exact dimensions and smooth surfaces, it reduces the likelihood of premature wear and tear, thereby extending the lifespan of the parts.

The Benefits of Precision CNC Machining for New York Industries

Precision CNC machining brings numerous benefits for New York industries. It allows for the manufacturing of complex parts with high accuracy, thereby enhancing the performance and reliability of various machinery and equipment. This leads to improved operational efficiency and productivity, which are crucial in today’s competitive business landscape.

Furthermore, precision CNC machining reduces waste and lowers production costs. By minimizing errors and rework, it ensures that resources are used efficiently. This not only makes the manufacturing process more sustainable but also provides significant cost savings for businesses.

Lastly, precision CNC machining facilitates the implementation of automation and digitalization in the manufacturing sector. By enabling the production of precision parts at a high volume, it supports the use of advanced technologies like robotics and smart manufacturing systems, thereby driving innovation and growth in New York industries.

Advancements in Precision CNC Machine Shop Services

The field of precision CNC machine shop services has witnessed significant advancements in recent years. These include the development of multi-axis CNC machines, which can perform a wider range of machining processes with greater precision. They also offer enhanced flexibility, as they can handle a variety of materials and produce parts with complex geometries.

Another major advancement is the use of advanced software for CNC programming. This software not only simplifies the programming process but also allows for simulation and testing, thereby improving the accuracy and efficiency of the machining process.

Furthermore, the integration of IoT (Internet of Things) technologies into CNC machines has paved the way for real-time monitoring and predictive maintenance. This not only prevents machine downtime but also optimizes the manufacturing process, thereby enhancing productivity and profitability.

Selecting the Right Precision CNC Service Provider in New York

When selecting a precision CNC service provider in New York, there are several factors to consider. First and foremost, the provider should have the necessary technical capabilities, including advanced CNC machines and skilled machinists. They should also offer a wide range of services, from primary machining processes to secondary operations like heat treating and finishing.

The provider should have a strong track record of delivering high-quality parts on time. This can be verified by checking their customer reviews and testimonials.

The provider should be committed to continuous improvement and innovation. They should embrace the latest advancements in CNC technology and strive to provide the best possible solutions for their customers.

Precision CNC machine shop services play a pivotal role in New York’s industrial sector. By delivering high-quality parts with precision and consistency, they enhance the performance and efficiency of various industries, thereby contributing to the city’s economic growth.

New York is home to a diverse range of CNC machine shops, each offering unique capabilities and services. Here’s a look at some of the top contenders in the area:

- I2R CNC – Imagination to Reality: Known for its family-run business ethos, I2R CNC has garnered praise for its professional, friendly staff and the impeccable quality of work. Clients highly recommend their services, which suggests a strong track record of customer satisfaction.

- Jdl Precision CNC Machine & Others: This shop is part of a list that includes several other notable names like Crown Precision and Winston Tool. They’ve earned recognition for their rapid service, such as welding and machining cracks in wheels in just one hour, a testament to their efficiency and skill.

- Xometry: Xometry stands out as a global leader in industrial-grade CNC machining. They provide custom CNC machining services tailored to engineers, product developers, and designers’ needs in New York. Their commitment to quality assurance and custom part specifications makes them a reliable choice for various industries.

- Roberson Tool: With over two decades of experience, Roberson Tool has been serving New York City with precision CNC machining. They focus on creating top-notch documentation and processes, catering to all precision CNC machining needs in the area. Their long-standing presence indicates a sustained commitment to quality and client service.

- Owens Industries: Established in 1944, Owens Industries offers top-tier CNC machine shop services characterized by unparalleled precision and craftsmanship. They excel in intricate prototyping and crafting customized parts, catering to both straightforward and advanced designs. Their reputation is built on decades of delivering high-quality, precise components.

| Shop Name | Address |

|---|---|

| I2R CNC Imagination to Reality | Multiple locations: 23 Roselle St, Mineola, NY 11501; 141 Flushing Ave New York, NY 11205; 4709 30TH St Long Island City, NY, 11101-3428. |

| Crown Precision | 1802 Kings Hill Rd, Penn Yan, New York, 14527, United States. |

| Xometry | 6116 Executive Blvd #800, North Bethesda, United States. |

| Roberson Tool | 4416 Glaser Hollow Rd, Bland, Missouri 65014. |

| Owens Industries | 7815 S 6th Street, Oak Creek WI 53154 USA. |