At Knowcnc.com, we offer an extensive and insightful exploration into the world of CNC milling and machining. Our website is a dedicated resource for both enthusiasts and professionals in the field, providing a comprehensive look at the various facets of CNC technology, its applications, advancements, and educational aspects.

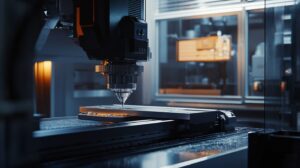

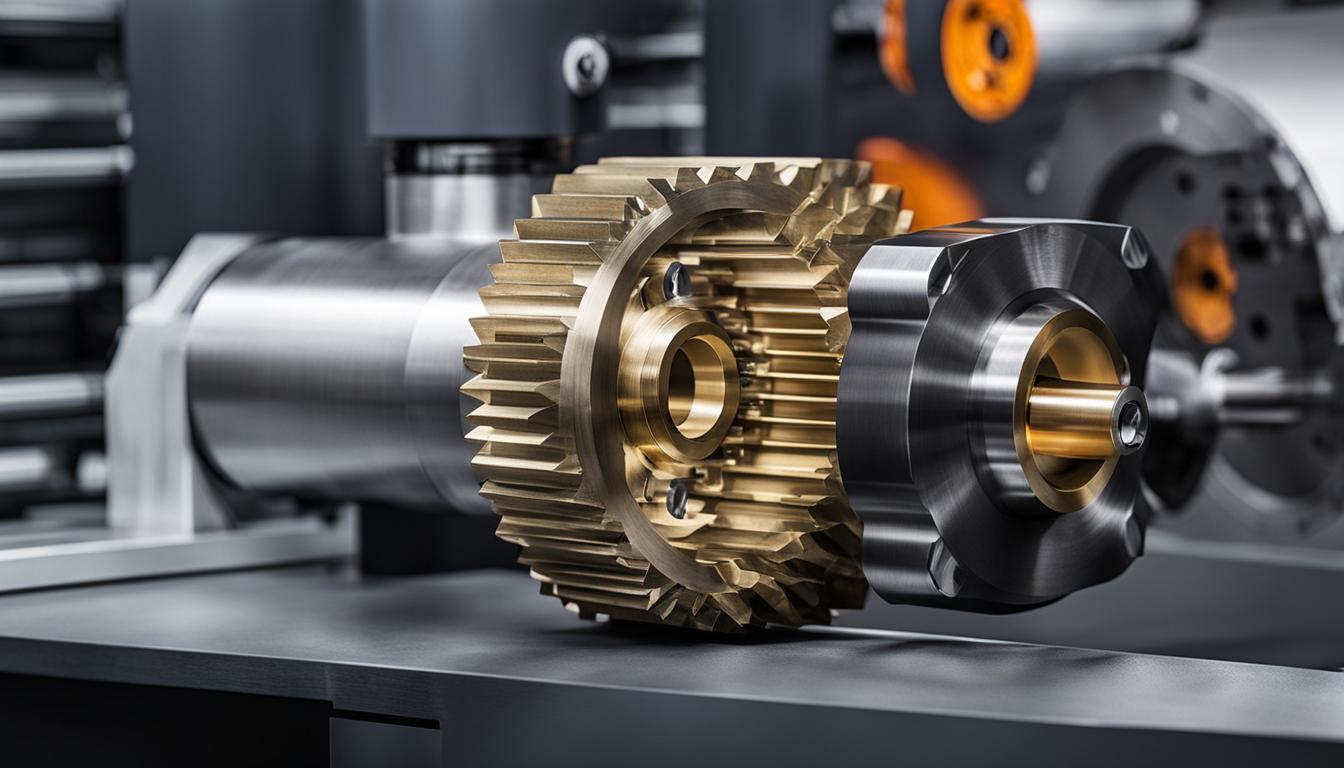

We delve deeply into the specifics of CNC milling, a process where computer-controlled machines carry out complex milling operations. Our content explains how these operations are meticulously pre-programmed and executed by the machines, ensuring unparalleled precision and consistency. This is particularly advantageous for tasks that are either too complex for manual execution or require high levels of repetition. We emphasize the numerous benefits of CNC milling, such as its ability to precisely follow instructions, the reproducibility of operations without extra effort, and the simplicity with which it handles complex tasks.

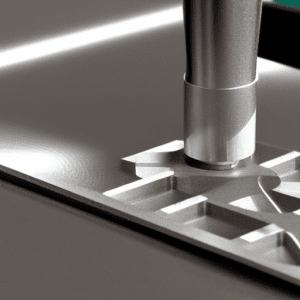

We also focus on the versatility of CNC machines. These machines are capable of working with a variety of materials, and we provide specific insights into the milling of different materials. For example, we discuss milling aluminum, a material valued for its combination of lightness and strength, making it ideal for applications where both qualities are essential. Our website explores how aluminum can be milled into various shapes and forms, demonstrating the material’s adaptability and the precision of CNC machining.

-

10 Must-Know CNC Techniques for Aspiring Machinists

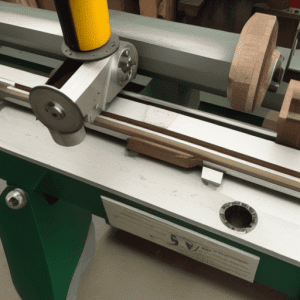

Aspiring machinists should master these 10 essential CNC techniques to excel in their field: precision tool selection, optimal cutting speed and feed rate determination, effective workpiece setup and fixturing, proper program creation and verification, strategic tool path planning, accurate dimensional measurement and quality control, efficient chip management and evacuation, coolant application and management, machine maintenance…

-

10 Tips to Customize Your CNC Software for Better Accuracy

Customizing your CNC software for better accuracy involves several key strategies. Start by calibrating your machine’s axes and tools regularly to ensure precise movements. Implement advanced error compensation techniques, such as backlash and thermal expansion corrections, to account for mechanical imperfections. Optimize your toolpath generation by using high-quality CAM software and adjusting feed rates and…

-

2024’s Top Innovations in CNC Machining: What’s New and Next?

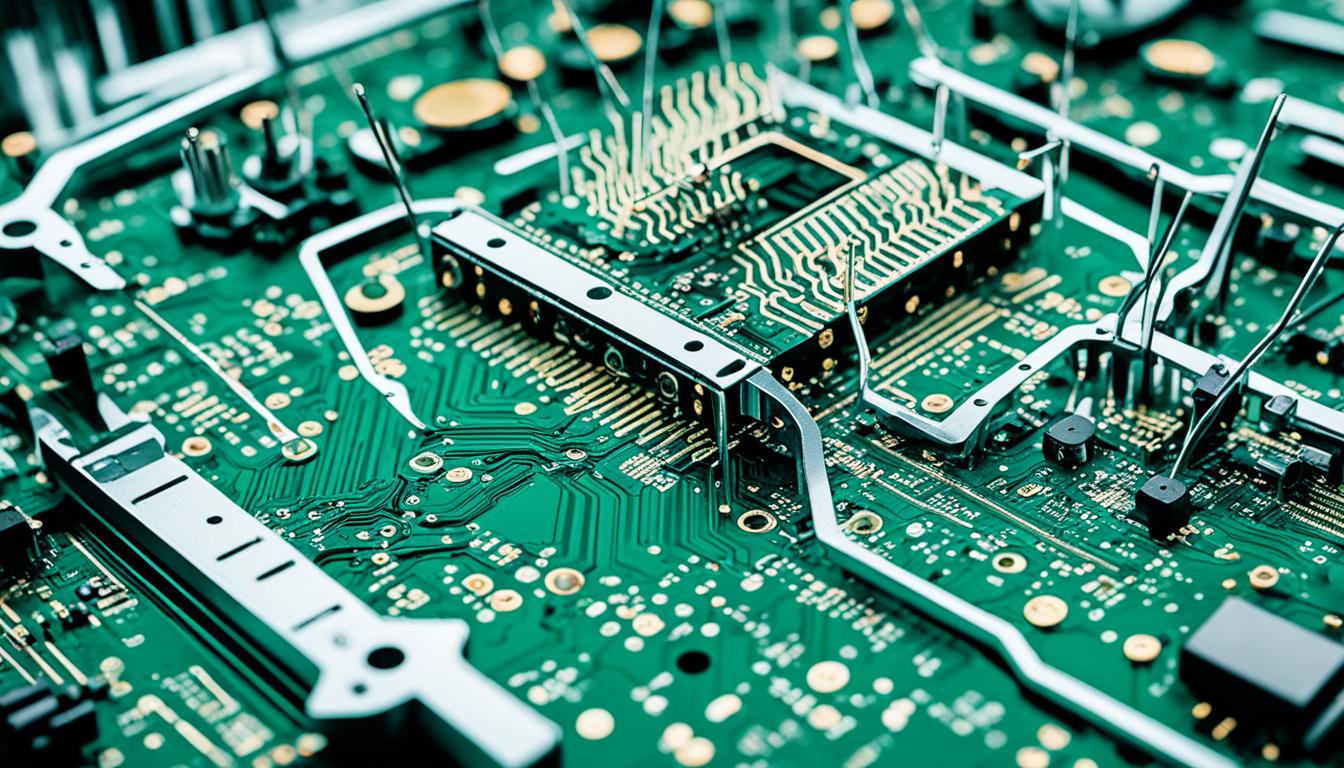

As the manufacturing industry advances rapidly, 2024’s top innovations in CNC machining lead the way in shaping the future of machining, transforming the way components and products are designed and created. Recent breakthroughs involving CNC machining advancements pave the way for new trends in CNC machining, benefiting producers and consumers alike. Driven by Industry 4.0,…

We are committed to keeping our audience informed about the latest trends and innovations in CNC machining. Our website features articles and discussions on topics like the impact of virtual reality on CNC education, the role of CNC machining in renewable energy, and the emergence of personal CNC machines. These topics not only reflect the current state of the industry but also offer a glimpse into its future, highlighting how CNC technology continues to evolve and adapt to new challenges and opportunities.

We strive to be your go-to source for all things related to CNC milling and machining. Whether you’re a seasoned professional or a curious newcomer to the field, our website is designed to provide you with the knowledge and insights you need to understand and excel in the world of CNC technology.