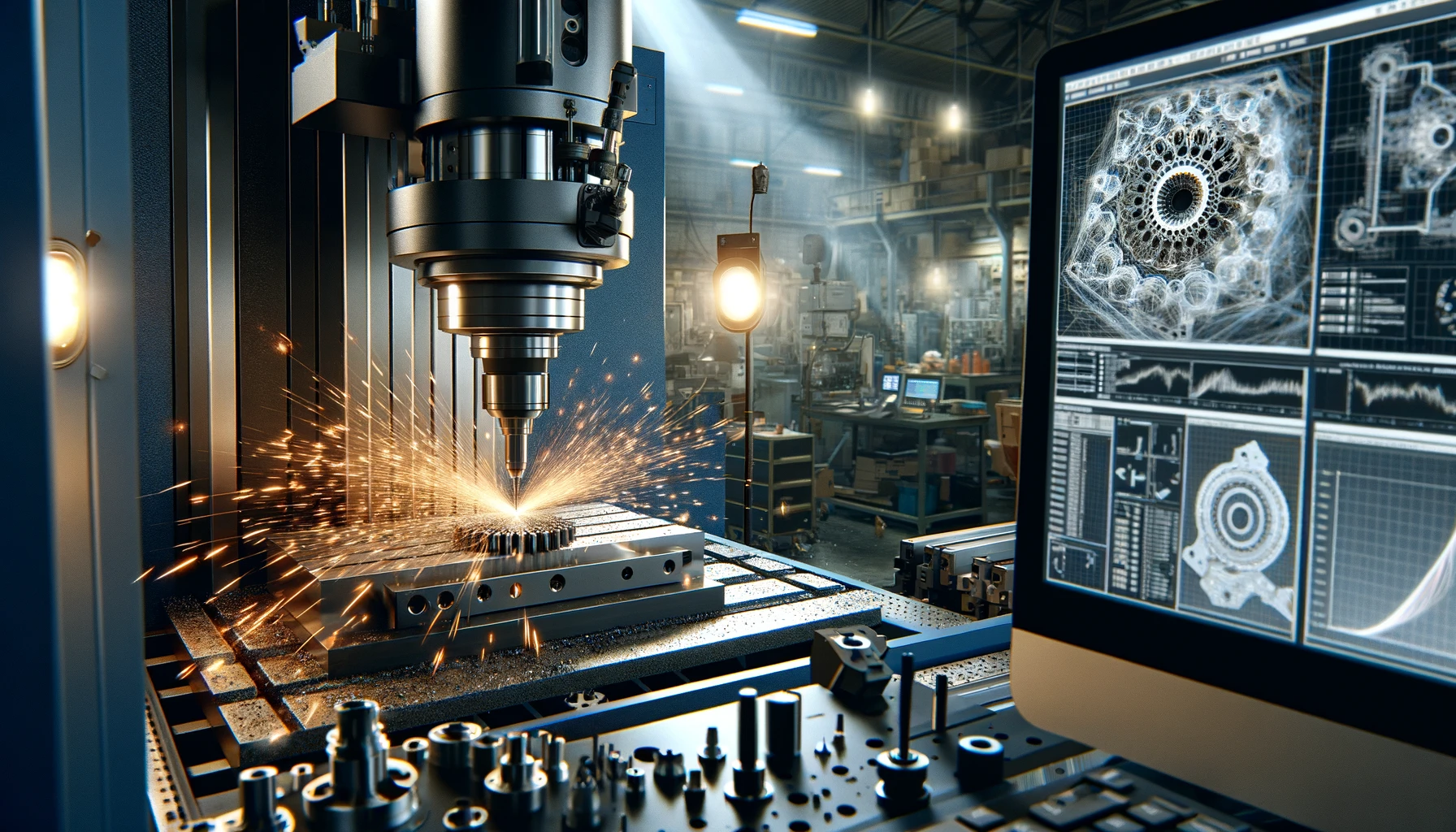

Five revolutionary CNC machining innovations transforming manufacturing are multi-axis machining, hybrid manufacturing, artificial intelligence integration, cloud-based CNC systems, and advanced simulation software. Multi-axis machining allows for complex geometries and reduced setup times by enabling tools to approach workpieces from various angles. Hybrid manufacturing combines additive and subtractive processes, offering greater design flexibility and material efficiency. AI integration in CNC machines enhances predictive maintenance, optimizes cutting parameters, and improves overall efficiency.

Cloud-based CNC systems facilitate remote monitoring, real-time data analysis, and seamless integration with other manufacturing processes. Advanced simulation software enables virtual testing and optimization of machining processes, reducing errors and material waste. These innovations collectively improve precision, efficiency, and flexibility in manufacturing, leading to higher quality products, reduced production times, and lower costs. By embracing these technologies, manufacturers can stay competitive in an increasingly demanding market, meeting the growing need for complex, customized parts across various industries.

- Revolutionary CNC machining innovations are driving a new industrial revolution in the manufacturing sector.

- Advanced manufacturing technologies are enabling production capabilities previously deemed unattainable.

- The integration of smart systems and CNC is redefining efficiency and precision in production workflows.

- Complex components can now be realized with unmatched accuracy, opening up new possibilities for design and functionality.

- These CNC advancements are setting new industry standards and paving the way for the future of manufacturing.

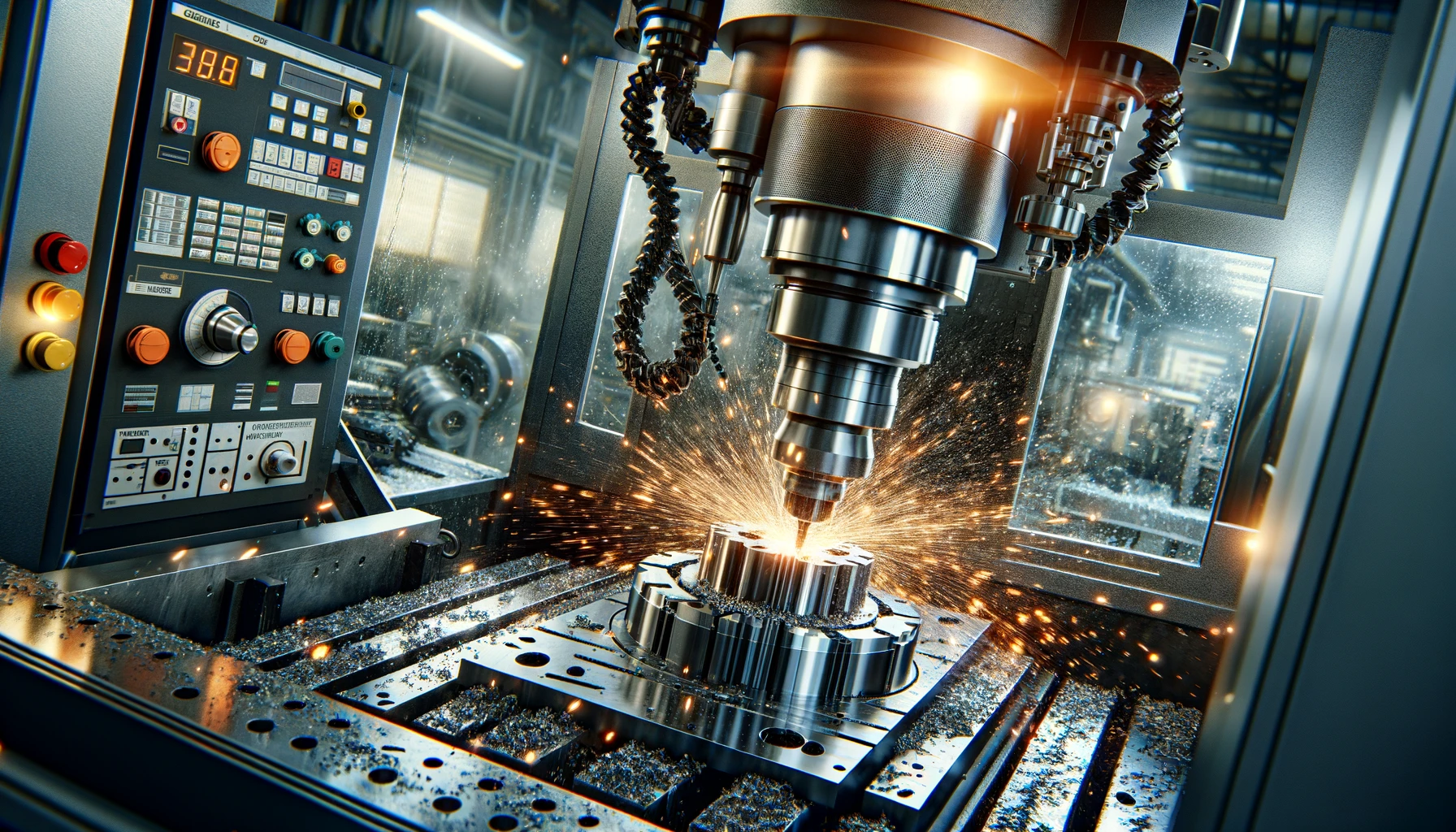

The Impact of High-Speed Machining on Production Efficiency

Within the sphere of modern manufacturing, high-speed machining (HSM) stands out as a groundbreaking progression in CNC machining. This innovation is pivotal in enhancing production efficiency, a term synonymous with the success of industrial operations. HSM technology propels manufacturing capabilities forward by streamlining cycle times, extending tool life, and thus escalating throughput while simultaneously reducing operational costs.

When we delve into the quantitative improvements brought about by HSM, it becomes evident how substantial its impact on production is. Consider the reduced cycle times: HSM offers machinists the capability to operate at higher cutting speeds without sacrificing precision, resulting in a significant downturn in time taken per component. The interplay between HSM and production efficiency is further exemplified by the life span of cutting tools, which is considerably prolonged due to the optimized cutting conditions, thereby reducing the frequency and costs of tool replacement.

To crystallize these benefits, the following table portrays the stark differences between conventional machining and HSM in key performance metrics:

| Metric | Conventional Machining | High-Speed Machining |

|---|---|---|

| Average Cycle Time | 30 minutes | 10 minutes |

| Tool Life Span | 5,000 components | 15,000 components |

| Average Setup Time | 1 hour | 20 minutes |

| Throughput Increase | — | Up to 200% |

| Cost Reduction (%) | — | 20-30% |

These figures are illustrative of the manufacturing innovations that HSM introduces into the fabrication process. It becomes irrefutable that the adoption of high-speed CNC machining techniques is not simply an operational upgrade but a strategic investment. Businesses vested in the manufacturing domain cannot afford to overlook the transformative potential HSM wields in galvanizing production efficiency.

- Increase in Production Speed: HSM facilitates higher cutting speeds, directly translating into more parts produced per unit of time.

- Tool Longevity: The reduction in mechanical stresses and heat on tools during HSM operations drastically lowers wear, leading to fewer tool changes.

- Enhanced Precision: High-speed spindles and advanced control systems contribute to greater accuracy, reducing waste and rework.

- Economic Benefits: The culmination of speed, tool life, and precision presents a powerful economic case through cost savings and increased output.

These points succinctly embody the advantageous nature of integrating HSM into CNC practices, underscoring its role as a milestone among manufacturing innovations. In conclusion, those who harness the potential of high-speed machining secure for themselves a formidable competitive edge in today’s relentless manufacturing landscape.

Adoption of Multi-Axis CNC Machines for Complex Geometry

The manufacturing industry is currently witnessing a transformative shift with the introduction and adoption of multi-axis CNC machines, renowned for their ability to sculpt intricate and complex geometries with unprecedented precision. These advanced manufacturing systems are defining the future of how products are engineered and produced, enhancing both design capabilities and operational efficiencies.

Enhancements in 5-Axis Machining Capabilities

The recent advancements in 5-axis machining capabilities have propelled manufacturing into a new realm of possibilities. 5-axis CNCs are instrumental in executing complicated cuts and detailed geometries which were once deemed impractical or too time-consuming. Features like simultaneous movement and the ability to approach the workpiece from any direction have reduced the need for multiple setups, ensuring higher degrees of accuracy and superior surface finishes.

- Greater tool accessibility for intricate geometries

- Minimized tool vibration, leading to enhanced precision

- Capability to fabricate more complex parts without sacrificing speed

Implementing 6-Axis CNC for Enhanced Precision

Building upon the versatility of 5-axis machines, the integration of 6-axis CNC precision into the manufacturing sector has ushered in even more advanced levels of detail and exactitude. With an additional rotational axis, 6-axis machines offer an extended range of motion, enabling the flawless execution of extremely complex designs that demand tight tolerances and high-quality surface finishes.

- Extended range of movement and flexibility in manufacturing

- Higher precision for multi-faceted, intricate part geometries

- Streamlined production workflows, reducing the need for secondary operations

Reduction in Setup Time with Advanced Multi-Axis Systems

Advanced multi-axis systems have markedly reduced setup times by allowing for the handling of parts that require multiple machining processes in a single setup. This consolidation streamlines operations, curtails production timelines, and diminishes human error, resulting in substantial cost savings and productivity increases for manufacturers who venture into advanced manufacturing technologies.

| Feature | Impact on Setup Time | Operational Benefit |

|---|---|---|

| Single setup for complex parts | Significantly reduced | Increases machine utilization |

| Automated tool calibration | Minimized setup adjustments | Enhanced production consistency |

| Programmable work holding | Eliminates manual re-fixturing time | Accelerated throughput |

Integration of CNC with Additive Manufacturing Techniques

The fusion of CNC manufacturing innovations with additive manufacturing techniques is igniting a manufacturing transformation. This integration is more than a simple combination; it’s a synergetic relationship that expands the frontiers of what’s possible in modern manufacturing. As these domains intersect, they lay the groundwork for a versatile manufacturing ecosystem—one capable of producing parts with intricate internal geometries, optimized for weight, strength, and material use.

In aerospace and medical device manufacturing, the amalgamation of subtractive CNC processes with additive methodologies is leading to significant improvements in component performance and manufacturing workflows. By using additive techniques to create a near-net-shape part, which is then precisely finished with CNC machining, manufacturers achieve superior accuracy and surface finish that additive manufacturing alone cannot provide.

- Material Savings: Additive techniques can reduce waste by creating structures layer by layer, only using material where needed.

- Design Freedom: Complex geometries that are challenging or impossible to achieve with traditional CNC can be realized through additive manufacturing.

- Performance Optimization: Combining these methods allows parts to be lightweight yet strong, with internal structures optimized for specific applications.

Below is a comparison table showcasing the distinct advantages brought by the integration of CNC with additive manufacturing techniques:

| Characteristic | CNC Machining | Additive Manufacturing | Integrated Approach |

|---|---|---|---|

| Material Utilization | Higher waste due to subtractive nature | Efficient use, layer by layer construction | Combined efficiency, less waste than CNC alone |

| Design Complexity | Limited by tooling and access | Allows for highly complex structures | Complexity of additive with precision finishing of CNC |

| Surface Finish | Superior surface quality | May require post-processing for smoothness | Smooth finish with additive’s complex geometry |

| Manufacturing Speed | Fast for simple geometries | Slower, dependent on part complexity | Optimized time-to-part by leveraging strengths of both |

| Customization | Favors mass production | Ideal for one-offs and custom parts | Facilitates customization with mass production efficiency |

The hybridization of CNC and additive manufacturing is not just a trend but a significant leap forward, offering unprecedented flexibility and precision. As technology advances, the potential for these integrated methods to redefine manufacturing practices becomes increasingly evident. From on-demand production to lightweight, high-strength components, this is a true revolution in making, marking a pivotal moment in the storied history of manufacturing.

Smart CNC Machines: Incorporating Artificial Intelligence

The advent of smart CNC machines has marked a significant milestone in the evolution of manufacturing. These advanced systems merge the precision of CNC machining with the adaptability of artificial intelligence, resulting in a groundbreaking leap in production capabilities. As the manufacturing industry embraces this integration, the benefits of increased efficiency, data-driven optimization, and enhanced accuracy are becoming increasingly evident.

Self-Optimizing CNC Machines Learning from Data

One of the most transformative features of smart CNC machines is their ability to continuously learn and improve from processed data. This self-optimizing mechanism, powered by artificial intelligence, enables machines to analyze operational data, predict performance outcomes, and autonomously adjust their operations for optimal results. The application of these self-optimizing environments leads to considerable advancements in production efficiency and the minimization of waste.

Real-Time Decision Making with Embedded AI Systems

Artificial intelligence in manufacturing equips CNC machines with the capacity for real-time decision making. Embedded AI systems analyze live data streams, allowing the machines to make instant adjustments in response to various parameters such as tool wear, material inconsistencies, or changing design specifications. This dynamic approach ensures consistent quality while accelerating the pace at which manufacturing tasks are completed.

Improving Accuracy with Intelligent Error Correction

Intelligent error correction is a pivotal innovation in CNC machining. As AI-driven machines detect anomalies or deviations from expected patterns, they initiate corrective measures, thus maintaining the high accuracy levels required in precision manufacturing. This not only ensures the integrity of the final product but also drastically reduces the occurrences of rework and scrappage, bolstering the overall reliability of manufacturing processes.

| Feature | Benefit | Impact on Manufacturing |

|---|---|---|

| Data-Driven Optimization | Maximized Efficiency | Higher throughput with reduced operational costs |

| Real-Time Adjustments | Consistent Quality | Reduction in variability, enhancing product consistency |

| Intelligent Error Detection | Minimized Rework | Lower waste generation and improved sustainability |

Embracing the prowess of smart CNC machines, the manufacturing sector is experiencing an overhaul in traditional practices. The incorporation of AI not only streamlines operations but also paves the way for future CNC machining innovations that will continue to redefine the industry.

Advanced Material Use in CNC Machining for Improved Performance

The advent of advanced materials has been a game-changer for CNC machining, providing significant enhancements in the performance and durability of machined components. These material innovations are not only pushing the boundaries of what can be manufactured but also how long products last and how effectively they perform their functions. In industries where conditions can be extreme and the demand for precision is high, such developments in material science are invaluable.

Manufacturers are now utilizing a diverse array of new alloys and composite materials to meet the challenges of modern engineering demands. From aerospace to automotive, these high-performance materials are specially engineered to withstand harsh environments while maintaining structural integrity and precision. By integrating these advanced materials into CNC processes, businesses are achieving longer-lasting and more reliable products, which stands as a testament to the synergy between material science and precision machining.

- New Alloys: Incorporating elements like titanium and vanadium to enhance strength and corrosion resistance.

- Composite Materials: Utilizing carbon fiber composites for their unparalleled strength-to-weight ratio.

- Advanced Plastics: Leveraging polymers that can withstand high temperatures and chemical exposure.

Implementing these materials in CNC machining operations directly translates into improved performance across various metrics:

- Increased lifespan of components due to higher wear resistance.

- Enhanced ability to operate under high-stress conditions without deformation.

- Greater fuel efficiency in automotive and aerospace applications through lighter part design.

Every advancement in material use in CNC machining signifies a leap towards greater efficiency and innovation in manufacturing. By continuously developing and adopting such materials, industries are not only meeting today’s stringent performance criteria but are also shaping the future landscape of manufacturing excellence. As this trend progresses, the interplay between advanced materials and CNC technology will play a pivotal role in delivering superior performance and driving forward the industrial capabilities of tomorrow.

Automation in CNC Machining: Robotics and Unmanned Operations

As the manufacturing sector strives for greater efficiency and productivity, the implementation of automation in CNC machining has become a pivotal development. The integration of robotics and unmanned operations not only accelerates workflows but also provides consistency in high-quality production. This section dissects the three primary innovations driving this trend: collaborative robots (cobots), lights-out manufacturing, and automated tool changes.

Collaborative Robots Working Alongside CNC Operators

The introduction of cobots into the manufacturing environment is a game-changer for the economy of motion and labor optimization. These robots are designed to work side by side with human operators, contributing to tasks that require precision and endurance. By performing repetitive or dangerous tasks, cobots ensure that CNC operators can focus on oversight and the fine-tuning of machining processes.

Unmanned CNC Cells for Lights-Out Manufacturing

Lights-out manufacturing, the ability to run production without human intervention, is increasingly achievable through unmanned CNC cells. This level of automation empowers facilities to maintain output around the clock, significantly impacting lead times and overall productivity. The deployment of sensor technology and advanced control systems allows for real-time monitoring and seamless operations, ensuring that machining continues uninterrupted, even beyond conventional work hours.

Streamlining Production with Automated Tool Changes

Automated tool changes are crucial for reducing downtime between operations and maintaining a continuous workflow. CNC machines equipped with this automation capability can swiftly change tools without manual input, minimizing idle time and enhancing overall throughput. An automated tool changer can hold a variety of tool options, enabling a single CNC machine to perform multiple tasks successively without sacrificing speed or accuracy.

The Role of the Internet of Things (IoT) in CNC Machine Monitoring

The advent of the Internet of Things in manufacturing has initiated a transformative era in how factories and workshops monitor and manage CNC machine operations. Incorporating IoT CNC machine monitoring systems has not only enhanced the productivity of manufacturing floors but also precipitated a new wave of manufacturing innovations.

One of the major breakthroughs is the ability for real-time tracking of machine performance. This has enabled predictive maintenance – a proactive approach that anticipates potential failures before they occur. By leveraging the data collected via IoT sensors, manufacturers can minimize machine downtime, extend the life of their equipment, and allocate resources with unprecedented efficiency. To illustrate this shift towards a data-driven manufacturing environment, a comparative analysis of traditional CNC machine monitoring and IoT-enriched monitoring systems is presented.

| Feature | Traditional Monitoring | IoT-Enhanced Monitoring |

|---|---|---|

| Data Collection | Manual Checks | Automated in Real-Time |

| Maintenance Strategy | Reactive | Predictive & Preventive |

| Downtime | Higher Risks | Significantly Reduced |

| Resource Allocation | Less Optimized | Efficiency-Driven |

| Machine Lifespan | General Estimates | Extended with Data Insights |

| Error Detection | Largely Manual | Automated Alerts |

The practical applications of IoT in manufacturing go beyond monitoring. The collected data can inform decisions on the factory floor, refining production processes and enhancing product quality. Operators can now rely on a network of interconnected devices to provide comprehensive operational insight, making the manufacturing pipeline not just smarter, but also agile enough to adapt to market demands.

As industries worldwide continue to embrace these IoT-driven enhancements, we can anticipate a future where every aspect of manufacturing is interlinked, monitored, and optimized in real time, leveraging a constellation of data that illuminates the path to sustainable and innovative production practices.

Precision Machining Advancements with Nano-scale CNC

Emerging as a beacon of progress in the realm of manufacturing, nano-scale CNC represents a monumental leap forward in precision machining advancements. Redefining the boundaries of what is achievable, this technology is replacing age-old approaches with groundbreaking ultra-precision machining technologies. This transformative shift is not merely an incremental change; it is reshaping manufacturing methodologies and setting new industry benchmarks in terms of accuracy and detail.

Pioneering Ultra-Precision Machining Technologies

The evolution of ultra-precision machining technologies has made the once-thought-impossible, possible. By enabling the manipulation of materials at the molecular level, these pioneering advancements allow for the fabrication of components with exactitudes previously unattainable. The applications for such precise work are vast, but they have been particularly advantageous in fields that demand stringent specifications, like aerospace, defense, and research sectors.

Breakthroughs in Nano-machining for Electronics and Medical Industries

Specific industries such as electronics and medical devices have greatly benefited from nano-machining breakthroughs. In the high-stakes realm of electronics, for example, the ability to consistently produce parts with nanometer precision is critical for miniature, high-density components. Similarly, in the medical industry, the production of intricate devices used in minimally invasive surgery is reliant on advanced manufacturing techniques, affirming the pivotal role of nano-scale CNC in transforming manufacturing.

Surpassing Traditional Limits with Nano-scale Tooling

Nano-scale tooling is the tour de force behind these advancements, enabling manufacturers to not only meet but surpass the traditional limits of machining. The expert crafting of tools that function at this minuscule scale empowers creators with unprecedented control, culminating in products that are at the pinnacle of precision and performance. This final frontier of manufacturing prowess heralds a future where the minutest details yield the most substantial impacts, firmly cementing the status of nano-scale CNC as the epitome of manufacturing innovation.