Carbon 3D printing, also known as carbon fiber 3D printing, is a cutting-edge technology revolutionizing the field of additive manufacturing. One of the pioneers in this field is Carbon, Inc., a California-based digital manufacturing company that specializes in 3D printers. With their high-performance printers and innovative Continuous Liquid Interface Production (CLIP) process, Carbon is pushing the boundaries of what is possible in 3D printing.

Key Takeaways:

- Carbon, Inc. is a leading digital manufacturing company specializing in 3D printers using the CLIP process.

- The company offers a range of printers, including the M1, M2, and M3 models, as well as various materials and software products.

- Carbon has formed partnerships with notable companies such as Ford, Johnson & Johnson, and Adidas.

- Their hardware capabilities include Digital Light Synthesis (DLS) technology and cloud connectivity.

- Carbon offers a range of high-performance materials for their printers, including rigid polyurethane, epoxy, and elastomeric polyurethane.

The History of Carbon, Inc.

Carbon, Inc. is a pioneering company in the field of 3D printing, known for its innovative technologies and high-performance printers. Founded in 2013 by Dr. Alex Ermoshkin, along with input from Dr. Joseph DeSimone, Carbon set out to revolutionize the world of additive manufacturing.

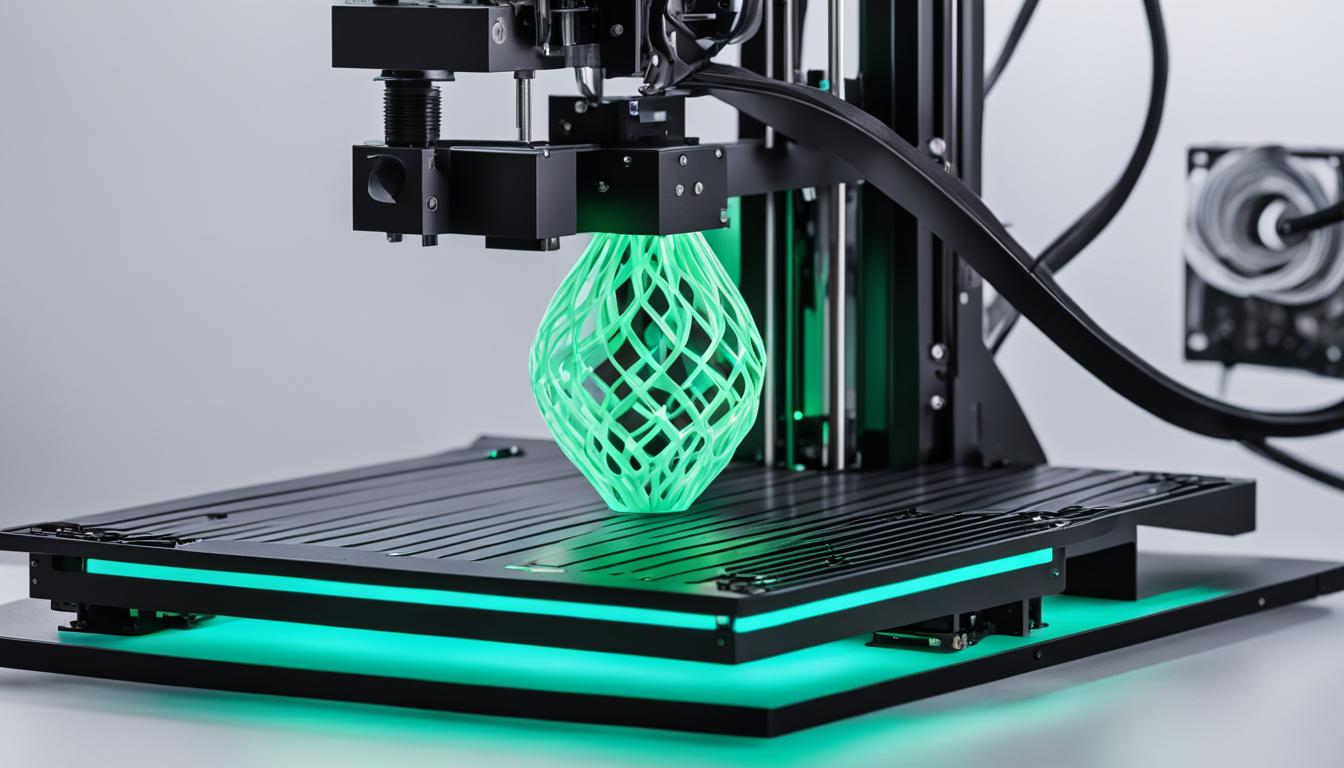

One of Carbon’s notable achievements is the development of the Continuous Liquid Interface Production (CLIP) process. This groundbreaking technology enables rapid and precise 3D printing by utilizing a combination of light and oxygen to cure liquid resin into solid objects. With CLIP, Carbon has overcome some of the limitations of traditional 3D printing, such as slow print speeds and limited material choices.

In 2015, Carbon unveiled a prototype of its 3D printer, showcasing the capabilities of the CLIP process. This innovative printer garnered significant attention and was even featured in a TED talk by Dr. DeSimone, attracting widespread interest from industry experts, investors, and enthusiasts.

Over the years, Carbon, Inc. has received substantial investments from renowned companies including Sequoia Capital, Google Ventures, and Adidas. This influx of funding has enabled Carbon to further develop its technology and expand its product portfolio, solidifying its position as a leader in the 3D printing industry. With a focus on continuous innovation, Carbon continues to push the boundaries of what is possible with 3D printing.

Carbon, Inc’s Achievements

| Year | Achievement |

|---|---|

| 2013 | Founding of Carbon, Inc. |

| 2015 | Introduction of 3D printer prototype using CLIP |

| 2016 | Securing investments from Sequoia Capital, Google Ventures, and Adidas |

| 2018 | Expansion of product portfolio with the M2 and M3 printer models |

| 2020 | Recognition as one of MIT Technology Review’s 50 Smartest Companies |

Carbon’s Range of Products

Carbon offers a range of 3D printers that cater to different needs and applications. Let’s take a closer look at their flagship models and programmable resins:

Carbon M1 Printer

The Carbon M1 printer was Carbon’s first offering and made a significant impact in the 3D printing industry. Although it has been replaced by newer models, the M1 set the foundation for Carbon’s advanced technology and high-quality prints.

Carbon M2 Printer

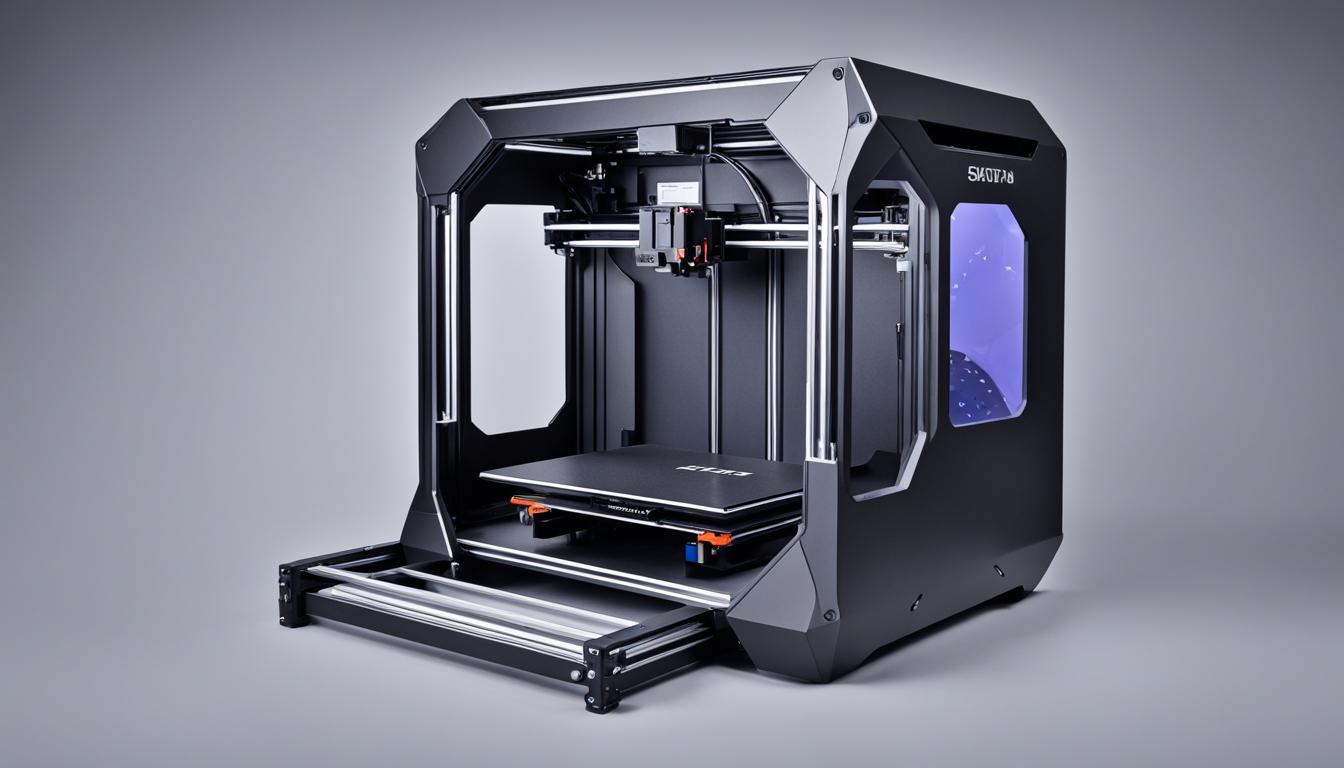

The Carbon M2 printer is the general-purpose printing device in Carbon’s lineup. Designed to deliver exceptional performance and versatility, the M2 enables users to create complex, functional parts with precision. This printer represents the evolution of Carbon’s technology and is widely used across industries.

Carbon M3 Printer

The Carbon M3 series printers were introduced in 2022 as an update to the M2 series. Building on the success of its predecessor, the M3 printers incorporate enhanced features and improvements, further optimizing the printing process for increased efficiency and superior results.

Programmable Resins

In addition to their range of printers, Carbon offers programmable resins that are specifically designed to work seamlessly with their printing technology. These resins provide users with a wide variety of material options, enabling the production of parts with diverse properties such as rigidity, flexibility, and heat resistance.

To ensure the best results, Carbon’s programmable resins undergo a UV cure process to define the overall geometry and a secondary thermal cure to set the final material properties. This precise curing process ensures that the printed parts achieve the desired mechanical and performance characteristics.

Furthermore, Carbon’s Smart Part Washer machine streamlines the post-processing and data recording workflow, allowing users to efficiently clean, inspect, and validate their finished 3D printed parts.

Carbon’s Range of Products

| Printer Model | Description |

|---|---|

| Carbon M1 | The first offering from Carbon, laying the foundation for their technology |

| Carbon M2 | A general-purpose printer known for its exceptional performance and versatility |

| Carbon M3 | An updated version of the M2 series with enhanced features and improvements, optimizing the printing process |

Carbon’s range of printers, combined with their programmable resins and Smart Part Washer, offers users a comprehensive solution for 3D printing with superior quality and efficiency. Whether it’s creating prototypes, end-use parts, or customized products, Carbon’s products enable users to unlock their full creative potential.

Carbon’s Hardware Capabilities

Carbon’s innovative hardware capabilities are at the forefront of the 3D printing industry. The company utilizes cutting-edge Digital Light Synthesis (DLS) technology, revolutionizing the way parts are produced. With DLS, Carbon printers are capable of creating isotropic parts with exceptional quality and performance.

To enhance the user experience and streamline workflow, Carbon printers are equipped with cloud connectivity. This built-in feature enables seamless integration with the digital ecosystem, unlocking a range of capabilities for users.

Cloud Connectivity

Carbon printers are designed to be cloud-connected by default, harnessing the power of the internet to enable a host of advanced functionalities. By harnessing cloud connectivity, Carbon empowers users with enhanced control and access to their printers, irrespective of their physical location.

| Benefits of Cloud Connectivity: | |

|---|---|

| Remote monitoring and control: | Keep track of print progress, manage print settings, and control the printer from anywhere using a web browser or mobile app. |

| Predictive maintenance: | Receive real-time alerts and notifications for maintenance requirements, ensuring optimal printer performance. |

| Over-the-air software updates: | Access the latest software updates and new features seamlessly, without the need for manual intervention. |

Cloud connectivity provides users with a seamless and efficient printing experience, giving them the flexibility and convenience to manage their printers with ease.

Carbon’s Materials

When it comes to materials, Carbon offers a diverse range of options for their printers. All of these materials are sold as liquid resin, providing flexibility and versatility in the printing process.

Carbon’s materials undergo a two-step curing process to achieve the desired properties. First, a UV cure process is utilized to define the overall geometry of the printed object. This step ensures precise and accurate results. Then, a secondary thermal cure is applied to set the final material properties, enhancing strength and durability.

Carbon’s material portfolio includes various options to cater to different applications and requirements. Some of the commonly used materials include rigid polyurethane, epoxy, elastomeric polyurethane, silicone urethane, and more. These materials offer different levels of hardness, flexibility, and resistance, allowing users to select the right material for their specific needs.

It is worth noting that Carbon collaborates with third-party vendors to expand their material offerings. By partnering with other trusted suppliers, Carbon ensures that their users have access to a wider selection of materials, further expanding the possibilities of their 3D printing platform.

In conclusion, Carbon’s materials play a crucial role in the 3D printing process, offering a range of options with unique properties. The combination of UV cure and thermal cure processes ensures the production of high-quality and functional end-use parts. With their diverse material portfolio and collaborative approach, Carbon empowers users to bring their innovative ideas to life with precision and reliability.

Carbon’s Partnerships and Awards

Carbon, Inc. has established strategic partnerships with renowned companies such as Ford, Johnson & Johnson, Adidas, and Lamborghini, leveraging their expertise to pioneer innovative projects and propel the application of 3D printing across diverse industries. These partnerships have resulted in groundbreaking collaborations that have revolutionized manufacturing processes.

Furthermore, Carbon has garnered significant recognition for their remarkable achievements. The company was honored as a WEF Tech Pioneer, acknowledging their profound impact on the technological landscape. Additionally, Carbon has been included in MIT Technology Review’s prestigious list of the 50 Smartest Companies, solidifying their position as an industry leader.

Carbon’s collaborations and accolades reflect their commitment to pushing the boundaries of 3D printing technology and forging groundbreaking advancements in the field. These partnerships enable Carbon to drive innovation and expand the capabilities of their cutting-edge solutions, while the recognition from esteemed institutions underscores their pioneering achievements.

Carbon’s Leadership Team

Carbon’s success can be attributed to the exceptional leadership team driving the company forward. Each member brings unique expertise and a shared commitment to innovation in 3D printing.

The Key Members:

- Craig Carlson: Joining Carbon in 2014 as the head of engineering, Craig Carlson plays a pivotal role in the development of cutting-edge technologies and ensures the company’s products remain at the forefront of the industry.

- Josh Green: As the general counsel, Josh Green provides invaluable legal expertise to Carbon. His guidance on intellectual property, contracts, and regulatory compliance ensures the company operates ethically and within legal boundaries.

- Elisa de Martel: Elisa de Martel serves as Carbon’s CFO, overseeing the financial operations of the company. With her strategic financial planning and management skills, she helps drive Carbon’s growth and investment strategies.

- Dara Treseder: As Carbon’s CMO, Dara Treseder spearheads the company’s marketing initiatives. Her expertise in global brand building and innovative marketing strategies has been instrumental in increasing Carbon’s market visibility and driving customer engagement.

- Ellen Kullman: Ellen Kullman is Carbon’s President and CEO, providing visionary leadership and strategic direction. With her extensive experience in executive roles and her commitment to innovation, she guides Carbon towards achieving its long-term goals and driving industry-wide change.

The Board of Directors:

Carbon’s board of directors comprises influential individuals who bring diverse perspectives and industry expertise to the table.

| Board Member | Background |

|---|---|

| Alan Mulally | Former CEO of Ford, Alan Mulally brings extensive experience in the automotive industry and a deep understanding of technology to Carbon’s board. |

| Jim Goetz | Sequoia Capital partner Jim Goetz’s insights and experience in venture capital contribute to Carbon’s strategic decision-making and long-term growth plans. |

With their combined expertise, the leadership team and board of directors guide Carbon in its mission to revolutionize additive manufacturing and drive innovation across industries.

Carbon’s Impact and Applications

Carbon’s innovations in additive manufacturing have revolutionized the field, making a significant impact on the industry. With their unique platform that combines software, hardware, and materials, Carbon has paved the way for the production of high-quality, isotropic end-use parts.

Through their advanced technology and continuous development, Carbon has established itself as one of the leading companies in the 3D printing industry. Their printers have been widely adopted across various sectors, including automotive, healthcare, and consumer goods.

The Carbon platform offers unparalleled capabilities and benefits, enabling manufacturers to streamline their production processes, reduce costs, and accelerate time-to-market. With the ability to produce complex geometries, intricate designs, and functional prototypes, Carbon has opened up new possibilities in product development and manufacturing.

Applications of Carbon’s Additive Manufacturing Technology

The applications of Carbon’s technology are vast and diverse, spanning across multiple industries:

- Automotive: Carbon’s additive manufacturing solutions have been embraced by automotive manufacturers for the production of lightweight, high-performance parts, such as interior components, air ducts, and custom automotive accessories.

- Healthcare: Carbon’s platform has made significant contributions to the healthcare industry, enabling the production of custom medical devices, prosthetics, and anatomical models. The ability to create patient-specific solutions has revolutionized personalized healthcare.

- Consumer Goods: Carbon’s technology has empowered consumer goods companies to create innovative and sustainable products. From footwear and apparel to electronics and household items, Carbon’s solutions have enhanced design possibilities and improved functional performance.

By partnering with leading companies and establishing collaborations, Carbon continues to expand the applications of their technology. They have established themselves as a trusted partner in the additive manufacturing ecosystem, enabling manufacturers to unlock the full potential of 3D printing.

List of 3D Printer Manufacturers

| Company | Specialization |

|---|---|

| Carbon, Inc. | Additive manufacturing |

| Stratasys | Industrial 3D printers |

| 3D Systems | Prototyping and production systems |

| Formlabs | Desktop 3D printers |

| HP Inc. | Multi Jet Fusion 3D printers |

These are just a few examples of the leading 3D printer manufacturers in the industry. Each company offers unique solutions and expertise, catering to different needs and applications in the additive manufacturing space.

Overall, Carbon’s impact and applications have reshaped the way we think about manufacturing. Their platform has paved the way for new possibilities, combining innovation, quality, and efficiency to drive the future of additive manufacturing.

Carbon’s Global Presence

Carbon, a digital manufacturing company specializing in 3D printing, has a global presence with offices in multiple locations around the world. While headquartered in Redwood City, California, Carbon serves customers in 11 countries, emphasizing their commitment to providing products and services on a global scale. This expansive reach enables Carbon to support customers across various industries, ensuring they can cater to specific needs and requirements.

International Offices

Carbon’s offices are strategically located in key regions to offer localized support and efficient service to their customers. The company’s international offices are set up in the following locations:

| Location | Country |

|---|---|

| Redwood City | United States |

| Tokyo | Japan |

| Munich | Germany |

| Pune | India |

| Sydney | Australia |

| Shanghai | China |

| São Paulo | Brazil |

| Paris | France |

| Toronto | Canada |

| Seoul | South Korea |

| Mexico City | Mexico |

Carbon’s Awards and Recognition

Carbon has gained widespread recognition and numerous prestigious awards for its remarkable technological innovations and significant contributions to the field of 3D printing. These accolades reinforce Carbon’s position as a frontrunner in the industry and highlight its unwavering commitment to pushing the boundaries of what is achievable in the world of additive manufacturing.

WEF Tech Pioneers: Carbon has been honored as a WEF (World Economic Forum) Tech Pioneer, a prestigious recognition that celebrates companies that exhibit cutting-edge technology and have the potential to contribute to global growth and progress.

MIT Technology Review’s 50 Smartest Companies: Carbon has rightfully earned a place among MIT Technology Review’s 50 Smartest Companies, a list that showcases organizations that excel in combining groundbreaking technology with innovative business strategies, setting new standards in their respective industries.

Fast Company Innovation by Design Award: Carbon’s relentless pursuit of innovation and exceptional design has been acknowledged with the Fast Company Innovation by Design Award, underscoring the company’s commitment to revolutionary ideas and pushing the boundaries of what is considered possible within the 3D printing landscape.

These prestigious awards and recognitions serve as a testament to Carbon’s outstanding achievements and reinforce its position as a leader in the industry. Through a relentless dedication to innovation and a steadfast commitment to excellence, Carbon continues to shape the future of 3D printing and inspire others to push the boundaries of what is possible.

Carbon’s Future Prospects

Carbon, Inc. is poised to shape the future of manufacturing with its ongoing innovation and expansion in the 3D printing industry. With a strong leadership team, strategic partnerships, and cutting-edge technology, Carbon is well-positioned for success.

As a leader in the additive manufacturing field, Carbon is at the forefront of revolutionizing the way products are created. Their commitment to pushing the boundaries of 3D printing opens up endless possibilities for the future of manufacturing.

One exciting possibility for Carbon’s future is the potential for an initial public offering (IPO). With their significant growth and success, an IPO could provide additional resources to fuel their expansion and enable them to reach new heights in the industry.

Key Factors Fueling Carbon’s Future Prospects

- Strong leadership team: Carbon’s leadership, led by President and CEO Ellen Kullman, brings a wealth of experience and expertise to the company. Their strategic guidance and vision drive the company’s growth and market presence.

- Strategic partnerships: Collaborations with industry giants such as Ford, Johnson & Johnson, Adidas, and Lamborghini showcase Carbon’s ability to form strategic partnerships that extend the reach and application of their 3D printing technology.

- Cutting-edge technology: Carbon’s hardware capabilities, utilizing Digital Light Synthesis (DLS), and their cloud connectivity features position them as pioneers in the 3D printing industry. Their continuous development of innovative solutions ensures they stay at the forefront of the market.

As Carbon continues to innovate and disrupt traditional manufacturing processes, the future looks bright for this innovative company. Their ability to deliver high-quality, isotropic end-use parts in various sectors, including automotive, healthcare, and consumer goods, solidifies their position as a leader in the industry.

With their global presence and commitment to customer satisfaction, Carbon is well-equipped to cater to the specific needs of industries worldwide. This widespread reach allows them to support various businesses and contribute significantly to the future of manufacturing.

Potential IPO and Growth Opportunities

An IPO could be a game-changer for Carbon, providing them with the capital necessary to accelerate their growth and expansion plans. With the increasing demand for 3D printing technology and the company’s strong market position, an IPO would not only attract more investors but also fuel further innovation in the industry.

Carbon’s advancements in 3D printing are transforming the manufacturing landscape. Their ability to produce high-quality, functional parts at scale and adapt to specific industry requirements solidifies their position as a key player in the future of manufacturing.

| Key Factors | Impact on Future Prospects |

|---|---|

| Continued innovation | Drives industry growth and market presence |

| Strategic partnerships | Expands reach and application of 3D printing technology |

| Cutting-edge technology | Pioneers new solutions and maintains competitive advantage |

| Potential IPO | Provides resources for accelerated growth and expansion |

Conclusion

Carbon 3D printing has revolutionized the field of additive manufacturing, paving the way for exciting innovations and future prospects. With their relentless dedication to pushing boundaries, Carbon has established itself as a leader in the industry. Through strategic partnerships and a diverse range of high-performance products, the company has redefined what is possible with 3D printing.

One of the key strengths of Carbon lies in its cutting-edge technology, such as the Continuous Liquid Interface Production (CLIP) process. This innovation enables the production of high-quality, isotropic parts with exceptional precision and durability. Carbon’s hardware capabilities, including Digital Light Synthesis (DLS) technology, further enhance their printers’ performance. Coupled with cloud connectivity, Carbon’s printers offer seamless remote monitoring, predictive maintenance, and over-the-air software updates.

With a global presence and a customer base spanning various industries, Carbon has demonstrated its ability to cater to diverse needs. Their partnerships with renowned companies like Ford, Johnson & Johnson, Adidas, and Lamborghini signify the trust and confidence placed in Carbon’s solutions. As they continue to expand and explore new applications, Carbon’s future prospects remain promising. The possibility of a potential IPO further emphasizes their potential for growth and influence in the industry.

In conclusion, Carbon 3D printing represents a groundbreaking technology that has redefined additive manufacturing. Through their relentless pursuit of innovation, strategic partnerships, and commitment to quality, Carbon has solidified its position as a leader in the industry. As they continue to push the boundaries of what is possible, it is certain that Carbon’s innovations will play a key role in shaping the future of manufacturing.