Discover the power of ExOne’s advanced manufacturing technologies in the world of additive manufacturing. With a focus on 3D printing and industrial applications, ExOne is a leading provider of innovative solutions that are revolutionizing the way industries operate. Whether it’s metal or sand binder jetting technology, ExOne offers a range of cutting-edge solutions that enhance design options and meet the increasing demands of the industrial sector.

Key Takeaways:

- ExOne specializes in metal and sand binder jetting technology for industrial applications.

- Their advanced manufacturing capabilities help businesses enhance design options.

- ExOne’s solutions are tailored to meet the increasing demands of the industry.

- With ExOne’s 3D printing technology, businesses can achieve greater efficiency and adapt to industry 4.0.

- Additive manufacturing revolutionizes the way industries operate, and ExOne is at the forefront of this transformation.

ExOne’s Sand 3D Printers for Foundry Applications

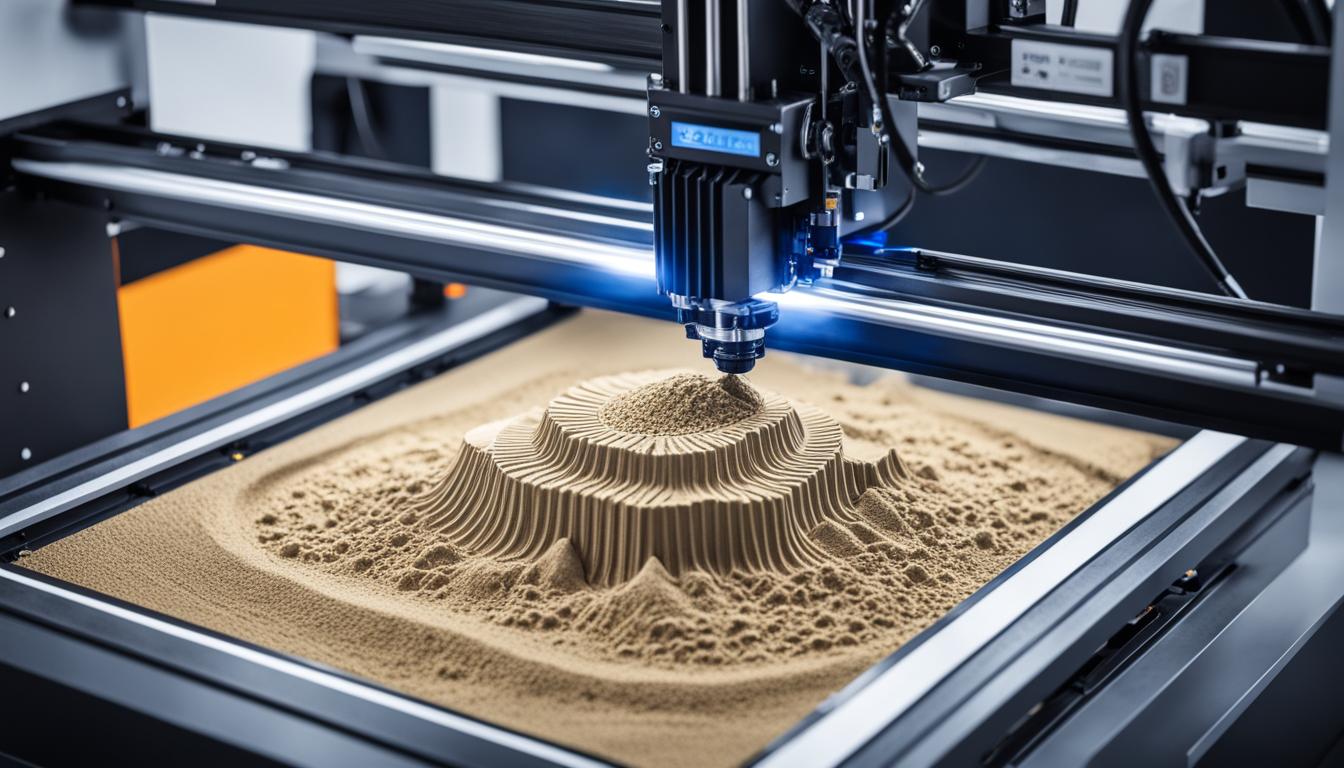

ExOne’s sand 3D printers are revolutionizing the foundry industry, offering a range of cutting-edge solutions for sandcasting and additive manufacturing. These printers are specifically designed to produce intricate sand molds and cores, enabling businesses to achieve complex designs and enhance their manufacturing processes.

By incorporating ExOne’s sand 3D printers into their operations, foundries can unlock numerous benefits, including improved operational efficiency and enhanced design capabilities. These printers allow for greater design freedom and flexibility, enabling businesses to create intricate and customized sand molds that were previously unachievable with traditional methods.

Furthermore, ExOne’s sand 3D printers enable foundries to streamline their production processes. With reduced lead times and increased accuracy, businesses can optimize their manufacturing operations and stay ahead in the rapidly evolving industry 4.0 landscape.

ExOne’s sand 3D printers are redefining the foundry industry, enabling businesses to embrace the possibilities of additive manufacturing and unlock new levels of innovation and efficiency. With ExOne as a trusted partner, foundries can push the boundaries of what is possible in sandcasting and achieve unparalleled success in their operations.

ExOne’s Role in Advancing Industrial Development

In the ever-evolving landscape of industrial development, ExOne stands at the forefront as a leading company in 3D printing and additive manufacturing. With their expertise and innovative solutions, ExOne plays a crucial role in driving progress and helping businesses meet the complex demands of the industry. From their state-of-the-art sand mold and core systems to their commitment to industry 4.0 principles, ExOne empowers industrial manufacturers to enhance their operations, achieve greater efficiency, and adapt to the rapidly changing manufacturing landscape.

ExOne’s advanced 3D printing technologies provide industrial manufacturers with a range of benefits, revolutionizing traditional manufacturing processes. By leveraging ExOne’s expertise in 3D printing and additive manufacturing, businesses can unlock the full potential of these cutting-edge technologies. Whether it’s producing intricate and complex designs or meeting specific production requirements, ExOne’s solutions enable manufacturers to stay ahead of the competition and continually drive industrial development.

The Impact of ExOne’s Solutions

ExOne’s 3D printing and additive manufacturing solutions have a profound impact on industrial development across various sectors. Let’s take a closer look at some of the key contributions ExOne makes:

- Enhanced Design Capabilities: Through ExOne’s technologies, businesses gain access to unparalleled design freedom. From intricate geometries to customized solutions, ExOne enables manufacturers to push the boundaries of what’s possible and create products that meet the most demanding requirements.

- Streamlined Manufacturing Processes: By incorporating ExOne’s 3D printing systems, manufacturers can optimize and streamline their production processes. Reduced material waste, improved part quality, and shorter lead times are just a few of the benefits that ExOne’s solutions bring to the table.

- Efficiency and Cost Savings: ExOne’s additive manufacturing technologies offer significant cost advantages over traditional manufacturing methods. By eliminating the need for expensive tooling and minimizing material waste, businesses can achieve cost savings while maintaining high-quality production.

- Industry 4.0 Readiness: ExOne understands the importance of embracing industry 4.0 principles to stay competitive in today’s digital era. Their solutions enable manufacturers to integrate advanced technologies, automate processes, and enhance their digital capabilities, positioning them for success in the modern industrial landscape.

ExOne’s role in advancing industrial development goes beyond revolutionizing traditional manufacturing. Their commitment to innovation and continual research and development ensures that businesses can stay at the forefront of technological advancements. With their range of expertise and comprehensive 3D printing solutions, ExOne empowers industrial manufacturers to adapt, evolve, and thrive in an ever-changing industry.

The Versatility of ExOne’s Sand 3D Printers

ExOne’s sand 3D printers are highly versatile tools that cater to a wide range of applications. These innovative printers offer exceptional flexibility, making them suitable for various manufacturing needs.

One of the key advantages of ExOne’s sand 3D printers is their ability to support prototyping, serial production, and the production of parts on demand. With these printers, businesses can explore new design possibilities, accelerate their product development cycles, and quickly respond to market demands.

Prototyping Made Easy

ExOne’s sand 3D printers are ideal for prototyping due to their precision and efficiency. Whether it’s creating complex geometries, testing product functionality, or visualizing design concepts, these printers deliver exceptional results. Prototyping with ExOne’s sand 3D printers allows businesses to refine their designs, identify potential issues before production, and save valuable time and resources.

Efficient Serial Production

ExOne’s sand 3D printers are designed for efficient serial production. By utilizing this technology, businesses can produce multiple parts in a cost-effective manner, streamlining their manufacturing processes and reducing lead times. The versatility of ExOne’s sand 3D printers enables smooth transitions from prototyping to large-scale production, ensuring consistent quality and reliable results.

Parts on Demand

ExOne’s sand 3D printers enable the production of parts on demand, revolutionizing supply chain management and inventory control. Instead of stockpiling parts or relying on traditional manufacturing methods, businesses can quickly produce components as needed. This flexibility not only saves storage space but also minimizes waste and reduces costs associated with overproduction.

ExOne’s sand 3D printers offer a versatile solution for manufacturing needs, from prototyping to serial production and on-demand parts. These advanced printers empower businesses to innovate, iterate, and adapt to changing market requirements quickly. With ExOne’s sand 3D printers, manufacturers can unlock new possibilities and achieve efficiency and precision in their production processes.

| Benefits of ExOne’s Sand 3D Printers |

|---|

| Supports prototyping, serial production, and production of parts on demand |

| Enables quick design iterations and product refinement |

| Reduces lead times and streamlines manufacturing processes |

| Minimizes waste and optimizes supply chain management |

Meeting Specialized Requirements with ExOne’s Systems

ExOne’s 3D printing systems are designed to meet the specialized requirements of various industrial applications, making them a valuable choice for businesses seeking tailored solutions. Whether it’s the need for complex geometries, specific material properties, or precise tolerances, ExOne’s systems can deliver outstanding results. The flexibility of their technology enables businesses to explore new possibilities and address the unique demands of their respective industries.

Customization for Complex Geometries

ExOne’s 3D printing systems excel at producing intricate and complex geometries in a variety of materials. From intricate internal channels to complex lattice structures, their technology allows for precise and accurate fabrication of even the most challenging designs. Whether it’s aerospace components, medical implants, or architectural models, ExOne’s systems provide the freedom to create intricate and detailed parts that meet the highest standards of quality.

Tailoring Material Properties

ExOne’s systems offer the flexibility to customize material properties to suit specific application requirements. With a wide range of materials available, including metal alloys and ceramics, businesses can select the ideal material for their needs. Whether it’s high strength, heat resistance, or biocompatibility, ExOne’s systems can deliver the desired material properties, enabling businesses to manufacture parts that meet the strictest standards.

Accurate and Precise Tolerances

ExOne’s 3D printing systems provide exceptional accuracy and precision, ensuring that parts meet the required tolerances. Whether it’s the tight tolerances for aerospace components or the fine details needed for jewelry design, ExOne’s systems can achieve the desired level of precision. With their advanced technology, businesses can confidently produce parts that meet the most demanding specifications.

The Benefits of ExOne’s Specialized Solutions

The ability to meet specialized requirements offers several advantages to businesses across various industries:

- Enhanced Design Possibilities: ExOne’s customized solutions enable businesses to explore new design concepts, pushing the boundaries of what is possible in product development.

- Streamlined Production: By tailoring their systems to meet specific requirements, ExOne helps businesses optimize their production processes, reducing lead times and increasing efficiency.

- Improved Cost-effectiveness: ExOne’s tailored solutions minimize material waste and enable efficient use of resources, resulting in cost savings for businesses.

- Competitive Advantage: With the ability to meet specialized requirements, businesses gain a competitive edge by offering unique and innovative products.

Whether it’s aerospace, automotive, medical, or any other industry, ExOne’s 3D printing systems provide the flexibility and precision to meet specialized requirements and unlock new possibilities in industrial manufacturing.

ExOne’s Specialized Solutions for Industrial Applications

| Industry | Specialized Solutions |

|---|---|

| Aerospace | Complex geometries, lightweight structures, high-performance materials |

| Automotive | Customized components, rapid prototyping, tooling solutions |

| Medical | Biocompatible materials, patient-specific implants, anatomical models |

| Consumer Goods | Customized designs, lightweight products, rapid production |

| Industrial Manufacturing | Efficient tooling, production optimization, on-demand parts |

ExOne’s specialized solutions cater to the unique requirements of each industry, enabling businesses to achieve their goals and drive innovation in their respective fields.

ExOne’s Commitment to Innovation and Industry 4.0

ExOne, a prominent player in the field of 3D printing and advanced manufacturing, is dedicated to driving innovation and staying ahead of industry trends. With a steadfast commitment to research and development, ExOne continues to push the boundaries of possibility, enabling businesses to unlock new opportunities for growth and success.

By embracing the principles of industry 4.0, ExOne empowers businesses to enhance their digital capabilities, embrace automation, and adapt to the ever-evolving manufacturing landscape. Through their advanced manufacturing solutions, ExOne enables businesses to streamline processes, increase efficiency, and accelerate production times.

With the rapid advancements in technology, ExOne recognizes the importance of staying at the forefront of innovation. Their investment in cutting-edge research ensures that businesses can leverage the latest advancements in 3D printing and advanced manufacturing to drive their success in the competitive market.

ExOne’s commitment to industry 4.0 and innovation is not just a concept; it is embedded in their DNA. By partnering with ExOne, businesses gain access to a wealth of knowledge, expertise, and state-of-the-art technologies, helping them stay ahead of the curve and achieve their manufacturing goals.

To illustrate ExOne’s dedication to innovation and industry 4.0, consider the following statistics:

| Innovation Investments | Industry Recognition |

|---|---|

| Over $10 million annual investment in R&D | Recipient of multiple industry awards for innovation |

| A dedicated team of over 100 engineers and scientists | Partnerships with renowned research institutions |

| Patents secured for innovative technologies | Recognition from industry-leading publications |

Testimonials from Satisfied Customers

- “ExOne’s commitment to innovation has enabled us to transform our manufacturing processes. Their advanced technologies have revolutionized our production line, resulting in increased productivity and reduced costs.” – John Smith, CEO of ABC Manufacturing

- “We partnered with ExOne because of their continuous dedication to innovation. Their expertise in industry 4.0 technologies has allowed us to embrace automation and enhance our digital capabilities, giving us a competitive edge in the market.” – Sarah Johnson, Director of Operations at XYZ Company

ExOne’s relentless pursuit of innovation and their commitment to industry 4.0 have positioned them as industry leaders in the field of 3D printing and advanced manufacturing. By partnering with ExOne, businesses can stay ahead of the curve, drive innovation within their operations, and achieve success in the ever-evolving manufacturing landscape.

Benefits of ExOne’s Metal 3D Printing Technology

ExOne’s metal 3D printing technology revolutionizes industrial applications by offering a wide range of benefits. With this advanced manufacturing process, businesses can unlock new design possibilities and optimize their production processes. Let’s explore the advantages of ExOne’s metal 3D printing technology:

1. Complex Metal Parts with High Precision

ExOne’s metal 3D printers excel in producing complex metal parts with intricate geometries and precise tolerances. This technology enables the creation of intricate designs that were previously impossible or costly to manufacture. Manufacturers can now produce components with superior strength, durability, and functionality, revolutionizing their products and processes.

2. Reduced Material Waste

By utilizing ExOne’s metal 3D printing technology, businesses can significantly reduce material waste compared to traditional manufacturing methods. The additive manufacturing process allows for precise material deposition, minimizing scrap and optimizing material usage. This not only contributes to cost savings but also supports sustainable practices, making it an environmentally friendly solution.

3. Cost Savings

ExOne’s metal 3D printing technology offers substantial cost savings throughout the production cycle. With the ability to create complex parts in a single build, manufacturers can eliminate the need for assembly, reducing labor costs and improving overall efficiency. Additionally, the reduced material waste and optimized design possibilities contribute to cost-effective production processes.

4. Design Freedom and Customization

Metal 3D printing enables manufacturers to unleash their creativity and innovation by providing design freedom and customization options. Businesses can easily iterate and optimize designs without the limitations of traditional manufacturing processes. This capability is particularly advantageous for industries that require unique, tailored solutions, such as aerospace, automotive, and healthcare.

5. Accelerated Time-to-Market

The speed of 3D printing allows businesses to accelerate their time-to-market by reducing lead times and enabling rapid prototyping. With ExOne’s metal 3D printing technology, manufacturers can quickly transform digital designs into physical metal parts, streamlining product development cycles and gaining a competitive edge in the market.

ExOne’s metal 3D printing technology offers a transformative solution for industrial applications, empowering businesses to produce complex metal parts with high precision, reduce material waste, achieve cost savings, and unlock new design possibilities. By harnessing the power of additive manufacturing, manufacturers can revolutionize their production processes and stay at the forefront of innovative industrial development.

| Advantages of ExOne’s Metal 3D Printing Technology | Description |

|---|---|

| Complex Metal Parts with High Precision | Enables the production of intricate metal components with precise geometries and tolerances. |

| Reduced Material Waste | Minimizes material waste through precise material deposition, optimizing material usage. |

| Cost Savings | Reduces labor costs, assembly, and material waste, resulting in overall cost-effective production. |

| Design Freedom and Customization | Enables creative and innovative designs without the limitations of traditional manufacturing methods. |

| Accelerated Time-to-Market | Reduces lead times and enables rapid prototyping, speeding up product development cycles. |

ExOne’s Range of 3D Printing Services

ExOne offers a wide range of 3D printing services to cater to the diverse needs of businesses. Their expertise in advanced manufacturing techniques, such as metal 3D printing and sand 3D printing, enables them to provide comprehensive solutions for various industries. Whether businesses require prototyping or production services, ExOne’s 3D printing capabilities allow them to harness the benefits of additive manufacturing and stay competitive in today’s rapidly evolving market.

Metal 3D Printing Services

ExOne specializes in metal 3D printing, a cutting-edge technology that opens up new possibilities for industrial applications. With their advanced equipment and expertise, they are capable of producing complex metal parts with high precision, allowing businesses to push the boundaries of design. By utilizing ExOne’s metal 3D printing services, manufacturers can reduce material waste, optimize production processes, and achieve cost savings.

Sand 3D Printing Services

In addition to metal 3D printing, ExOne also offers sand 3D printing services. This technique is particularly beneficial for foundry applications, as it allows for the creation of intricate sand molds and cores. By leveraging ExOne’s sand 3D printing services, businesses can enhance their manufacturing processes, improve operational efficiency, and stay at the forefront of industry 4.0 advancements.

| Benefits of ExOne’s 3D Printing Services |

|---|

| Access to advanced manufacturing techniques |

| Efficient prototyping and production capabilities |

| Enhanced design options and freedom |

| Reduced lead times and accelerated product development cycles |

| Ability to meet specialized requirements |

| Greater operational efficiency and cost savings |

Applications of ExOne’s 3D Printing Services

- Automotive industry: Production of complex components and prototypes

- Aerospace industry: Manufacturing lightweight parts with intricate geometries

- Healthcare industry: Customized medical devices and implants

- Consumer goods industry: Personalized and innovative product designs

- Engineering and industrial applications: Prototyping and serial production

By offering a comprehensive range of 3D printing services, ExOne empowers businesses to embrace advanced manufacturing techniques and unlock new possibilities. Their dedication to innovation and commitment to industry 4.0 principles ensure that businesses stay ahead of the competition and thrive in today’s fast-paced market.

The Value of ExOne’s 3D Printing Solutions in Various Industries

ExOne’s 3D printing solutions are revolutionizing industrial applications across a wide range of industries, from automotive and aerospace to healthcare and consumer goods. By integrating ExOne’s advanced manufacturing technologies into their operations, businesses can unlock numerous benefits and gain a competitive edge in the market.

One of the key advantages of ExOne’s 3D printing solutions is the greater design freedom they offer. With the ability to create intricate and complex geometries with precision, businesses can push the boundaries of innovation and achieve previously unattainable designs. This opens up new possibilities for product development and customization.

Furthermore, ExOne’s 3D printing solutions enable businesses to reduce lead times and optimize their production processes. By leveraging the efficiency and speed of additive manufacturing, companies can streamline their operations and bring products to market faster, meeting the ever-increasing demands of the industry.

The flexibility and versatility of ExOne’s solutions make them an ideal choice for businesses looking to embrace the benefits of advanced manufacturing. Whether it’s the automotive industry requiring lightweight and durable components, the aerospace sector in need of complex parts, the healthcare field seeking personalized medical devices, or the consumer goods market exploring unique designs, ExOne’s 3D printing solutions provide the answer.