Can a CNC mill cut metal?

Yes, a CNC mill can cut metal. CNC mills are computer-controlled machines that are used to cut and shape a variety of materials, including metal. CNC mills use a variety of cutting tools, such as end mills, drills, and reamers, to cut and shape metal into the desired shape. The cutting tools are mounted on a spindle, which is driven by a motor. The motor is controlled by a computer, which is programmed with the desired cutting parameters. The cutting tools are then moved along the X, Y, and Z axes to cut the metal into the desired shape.The cutting speed and depth of the cut can be adjusted to achieve the desired results. CNC mills can be used to cut a variety of metals, including aluminum, steel, stainless steel, brass, and copper. The type of metal being cut will determine the type of cutting tool and cutting parameters that should be used. CNC mills are used in a variety of industries, including automotive, aerospace, and medical. They are used to create parts for cars, airplanes, and medical devices. CNC mills are also used to create custom parts for a variety of applications.

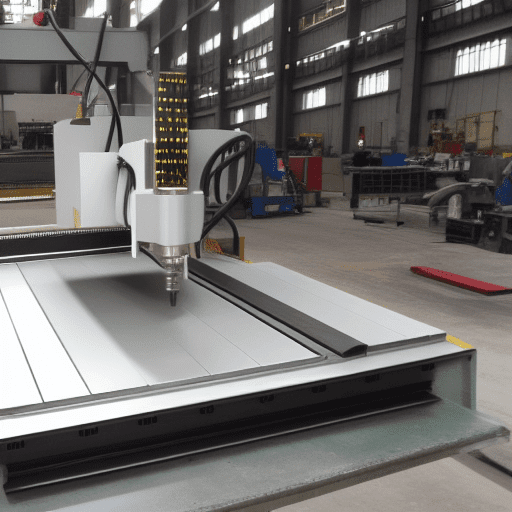

Can you cut metal with a CNC router?

Yes, you can cut metal with a CNC router. CNC routers are computer-controlled machines that are used to cut and shape materials such as wood, plastic, and metal. CNC routers are capable of cutting metal with a variety of tools, including end mills, drill bits, and engraving tools. The type of tool used will depend on the type of metal being cut and the desired finish. For example, end mills are used to cut aluminum, while drill bits are used to cut steel.

When cutting metal with a CNC router, it is important to use the correct cutting speed and feed rate. The cutting speed should be set to the recommended speed for the material being cut, and the feed rate should be set to the recommended rate for the tool being used. It is also important to use the correct cutting fluid to reduce friction and heat buildup.

In addition to the correct cutting speed and feed rate, it is important to use the correct cutting depth. The cutting depth should be set to the recommended depth for the material being cut. If the cutting depth is too shallow, the material may not be cut properly, and if the cutting depth is too deep, the material may be damaged.

Finally, it is important to use the correct cutting tool. The cutting tool should be chosen based on the type of metal being cut and the desired finish. For example, end mills are used to cut aluminum, while drill bits are used to cut steel. It is also important to use the correct cutting fluid to reduce friction and heat buildup.

Overall, CNC routers are capable of cutting metal with a variety of tools, including end mills, drill bits, and engraving tools. It is important to use the correct cutting speed and feed rate, cutting depth, and cutting tool for the material being cut. In addition, the correct cutting fluid should be used to reduce friction and heat buildup.

Can you CNC stainless steel?

Yes, it is possible to CNC stainless steel. CNC stands for Computer Numerical Control, and it is a process that uses computer-controlled machines to cut and shape materials. Stainless steel is a popular material for CNC machining because it is strong, durable, and corrosion-resistant. It is also relatively easy to machine, making it a great choice for a variety of applications.

When CNC machining stainless steel, the material is typically cut with a high-speed spindle and a cutting tool. The cutting tool is usually made of carbide or diamond, and it is designed to cut through the material quickly and accurately. The spindle is used to control the speed and direction of the cutting tool, and it is usually powered by a motor.

The CNC machining process begins with the creation of a 3D model of the part that needs to be machined. This model is then used to create a program that will control the machine and guide it through the machining process. The program will tell the machine how to move the cutting tool, how fast to move it, and how deep to cut into the material. Once the program is complete, the machine can begin machining the stainless steel.

The CNC machining process is highly accurate and can produce parts with tight tolerances. It is also relatively fast, making it a great choice for high-volume production. However, it is important to note that CNC machining stainless steel can be expensive, as the cutting tools and spindles used in the process are typically quite expensive. Additionally, stainless steel is a hard material, so it can be difficult to machine and may require special cutting tools.

How thick of metal can a CNC machine cut?

The thickness of metal that a CNC machine can cut depends on the type of CNC machine being used. Generally, CNC machines are capable of cutting metal up to 6 inches thick, although some machines are capable of cutting metal up to 12 inches thick. The type of metal being cut also affects the thickness that can be cut. For example, softer metals such as aluminum can be cut more easily than harder metals such as steel. Additionally, the type of cutting tool being used will also affect the thickness of metal that can be cut. For example, a plasma cutter is capable of cutting thicker metal than a router. The speed and power of the CNC machine also affects the thickness of metal that can be cut. Generally, the faster and more powerful the CNC machine, the thicker the metal it can cut.

Can routers cut metal?

No, routers cannot cut metal. Routers are woodworking tools that are used to cut and shape wood, plastic, and other soft materials. They are typically used to create decorative edges, hollow out an area in the middle of a piece of wood, or create grooves and slots. Routers are not designed to cut metal, and attempting to do so can cause serious damage to the router and the material being cut.

Metal cutting requires specialized tools such as saws, shears, and lathes. Saws are used to cut metal into pieces of a specific size and shape. Shears are used to cut metal into thin strips or sheets. Lathes are used to shape metal into round or cylindrical shapes. Each of these tools is designed to cut metal and can do so safely and efficiently.

In summary, routers are not designed to cut metal and attempting to do so can cause serious damage to the router and the material being cut. Metal cutting requires specialized tools such as saws, shears, and lathes.

Can you use a CNC machine for wood and metal?

Yes, you can use a CNC machine for both wood and metal. CNC stands for Computer Numerical Control, and it is a type of automated machining process that uses computer-controlled commands to cut and shape materials. CNC machines are used in a variety of industries, including woodworking, metalworking, and plastics manufacturing.

CNC machines are capable of cutting and shaping both wood and metal materials. For woodworking, CNC machines are used to create intricate designs and shapes, such as furniture, cabinetry, and musical instruments. For metalworking, CNC machines are used to create parts for cars, airplanes, and other machinery.

CNC machines are highly precise and can be programmed to cut and shape materials with great accuracy. They are also capable of producing complex shapes and designs that would be difficult or impossible to achieve with traditional machining methods.

CNC machines are also relatively easy to use and require minimal setup time. They can be programmed to cut and shape materials with a variety of tools, such as routers, drills, and saws. This makes them ideal for both large-scale and small-scale projects.

Overall, CNC machines are a great tool for both woodworking and metalworking. They are highly precise, easy to use, and capable of producing complex shapes and designs.

Can a CNC machine cut aluminum?

Yes, a CNC machine can cut aluminum. CNC stands for Computer Numerical Control, and it is a type of machining process that uses computer-controlled tools to cut and shape materials. CNC machines are used to cut a variety of materials, including aluminum. The process of cutting aluminum with a CNC machine involves using a cutting tool, such as a drill bit, to cut the aluminum into the desired shape. The cutting tool is attached to the CNC machine and is programmed to move in a specific pattern to cut the aluminum. The CNC machine is then able to cut the aluminum with precision and accuracy.

The type of cutting tool used to cut aluminum with a CNC machine depends on the type of aluminum being cut. For example, softer aluminum can be cut with a drill bit, while harder aluminum may require a router bit or end mill. The cutting tool is also chosen based on the desired finish of the aluminum. For example, a drill bit may be used to create a rough finish, while a router bit or end mill may be used to create a smoother finish.

The speed and accuracy of the CNC machine also affects the quality of the cut. The speed of the CNC machine is determined by the type of cutting tool being used and the type of aluminum being cut. The accuracy of the CNC machine is determined by the programming of the machine and the quality of the cutting tool.

In conclusion, a CNC machine can be used to cut aluminum. The type of cutting tool used, the speed of the CNC machine, and the accuracy of the CNC machine all affect the quality of the cut.

What do you call a machine that cuts metal?

A machine that cuts metal is typically referred to as a metal cutting machine. This type of machine is used to cut metal into various shapes and sizes. It can be used to cut sheet metal, bar stock, and even pipes. Metal cutting machines come in a variety of shapes and sizes, and can be powered by electricity, hydraulics, or pneumatics. Some of the most common types of metal cutting machines are shears, saws, lathes, milling machines, and laser cutters. Shears are used to cut sheet metal into various shapes, while saws are used to cut bar stock and pipes. Lathes are used to shape metal into cylindrical shapes, while milling machines are used to cut metal into flat shapes. Laser cutters are used to cut metal into intricate shapes with high precision. Metal cutting machines are used in a variety of industries, including automotive, aerospace, and construction.

What can a CNC machine cut?

A CNC (Computer Numerical Control) machine is a type of automated machine tool that is used to cut and shape a variety of materials. It is programmed to move in a specific pattern and can be used to cut a wide range of materials, including metals, plastics, composites, and wood. CNC machines are used in a variety of industries, including aerospace, automotive, medical, and consumer products.

CNC machines can be used to cut a variety of materials, including aluminum, brass, copper, steel, stainless steel, titanium, and other metals. They can also be used to cut plastics, composites, and wood. CNC machines are capable of cutting intricate shapes and patterns, as well as producing complex 3D shapes. They can also be used to cut intricate details, such as threads, grooves, and slots.

CNC machines are used in a variety of industries, including aerospace, automotive, medical, and consumer products. In the aerospace industry, CNC machines are used to cut and shape aircraft components, such as wings, fuselages, and landing gear. In the automotive industry, CNC machines are used to cut and shape car parts, such as engine blocks, transmissions, and exhaust systems. In the medical industry, CNC machines are used to cut and shape medical implants, such as prosthetics and orthotics. In the consumer products industry, CNC machines are used to cut and shape products, such as furniture, toys, and electronics.

CNC machines are highly precise and can be used to cut materials with a high degree of accuracy. They are also capable of cutting complex shapes and patterns, as well as producing intricate details. CNC machines are used in a variety of industries and can be used to cut a wide range of materials, including metals, plastics, composites, and wood.

Can a CNC machine cut sheet metal?

Yes, a CNC machine can cut sheet metal. CNC stands for Computer Numerical Control, and it is a type of automated machine that is used to cut and shape materials such as metal, wood, and plastic. CNC machines are programmed with a computer-aided design (CAD) software, which allows the machine to accurately cut and shape the material according to the programmed instructions. CNC machines are used in a variety of industries, including automotive, aerospace, and medical, and they are capable of cutting a wide range of materials, including sheet metal.

When cutting sheet metal with a CNC machine, the material is typically placed on a flat surface and secured in place. The CNC machine is then programmed with the desired cutting parameters, such as the type of tool to be used, the speed and depth of the cut, and the feed rate. Once the parameters are set, the CNC machine will then begin to cut the sheet metal according to the programmed instructions. Depending on the type of CNC machine being used, the cutting process can be done with a variety of tools, such as a router, drill, or laser.

CNC machines are capable of cutting sheet metal with a high degree of accuracy and precision, and they are often used to create complex shapes and designs. CNC machines are also capable of cutting sheet metal at a much faster rate than manual cutting methods, which makes them ideal for large-scale production runs. Additionally, CNC machines are relatively easy to operate and maintain, making them a popular choice for many manufacturing applications.

Can you cut stainless steel on a CNC router?

Yes, you can cut stainless steel on a CNC router. CNC routers are computer-controlled machines that are used to cut and shape materials such as wood, plastic, and metal. They are used in a variety of industries, including aerospace, automotive, and medical. Stainless steel is a type of metal that is highly resistant to corrosion and is often used in applications that require a high level of durability. It is also a popular choice for decorative applications.

When cutting stainless steel on a CNC router, it is important to use the right type of cutting tool. High-speed steel (HSS) tools are the most common type of cutting tool used for stainless steel. HSS tools are designed to cut through hard materials such as stainless steel and are available in a variety of shapes and sizes. It is also important to use the right cutting speed and feed rate for the material being cut. The cutting speed should be slow enough to prevent the tool from overheating, while the feed rate should be fast enough to ensure a clean cut.

In addition to using the right cutting tool and speed, it is also important to use the right type of coolant when cutting stainless steel on a CNC router. Coolants are used to reduce friction and heat buildup during the cutting process. Water-soluble coolants are the most common type of coolant used for stainless steel, as they are effective at reducing friction and heat buildup. It is also important to use the right type of lubricant when cutting stainless steel on a CNC router. Lubricants are used to reduce friction and wear on the cutting tool, and they can also help to reduce the amount of heat generated during the cutting process.

Overall, it is possible to cut stainless steel on a CNC router, but it is important to use the right type of cutting tool, cutting speed, feed rate, coolant, and lubricant. By using the right combination of these factors, it is possible to achieve a clean, precise cut on stainless steel.

How thick steel can laser cut?

Laser cutting is a process that uses a focused beam of light to cut through materials such as steel. The thickness of steel that can be cut with a laser depends on the type of laser being used, the material composition of the steel, and the thickness of the steel. Generally, laser cutting is most effective for steel that is up to 1/4 inch thick. However, some lasers are capable of cutting steel up to 1 inch thick.

The type of laser used for cutting steel is important because it determines the power of the laser beam and the speed at which it can cut. CO2 lasers are the most common type of laser used for cutting steel, and they are capable of cutting steel up to 1/4 inch thick. Fiber lasers are more powerful than CO2 lasers and can cut steel up to 1 inch thick.

The material composition of the steel also affects the thickness that can be cut. Steel that is harder or thicker will require a more powerful laser to cut through it. Steel that is softer or thinner can be cut with a less powerful laser.

Finally, the thickness of the steel also affects the laser cutting process. Thicker steel requires more power and a longer cutting time, while thinner steel can be cut more quickly.

In conclusion, the thickness of steel that can be cut with a laser depends on the type of laser being used, the material composition of the steel, and the thickness of the steel. Generally, laser cutting is most effective for steel that is up to 1/4 inch thick, although some lasers are capable of cutting steel up to 1 inch thick.