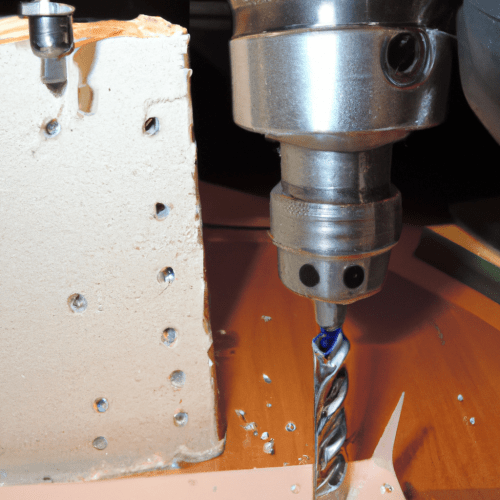

A milling drill is a type of power tool used for drilling into materials such as wood, metal, and plastic. It is a versatile tool that can be used for a variety of applications, including drilling holes, countersinking, reaming, and tapping. The milling drill is equipped with a rotating cutting tool, usually a drill bit, that is used to cut into the material. The drill bit is held in place by a chuck, which is tightened or loosened to adjust the depth of the cut. The milling drill is powered by an electric motor, which is connected to a gearbox that controls the speed and torque of the drill bit. The speed and torque of the drill bit can be adjusted to suit the material being drilled and the desired result. The milling drill is a powerful tool that can be used to create precise and intricate shapes in a variety of materials. It is an essential tool for any workshop or job site.

What is a milling drill used for?

A milling drill is a type of drill used for milling, which is a machining process that involves the use of rotary cutters to remove material from a workpiece. This type of drill is typically used to create precise holes and shapes in a variety of materials, including metal, wood, and plastic. It is also used to create slots, grooves, and other features in a workpiece. The milling drill is typically used in industrial settings, such as factories and workshops, but can also be used in home workshops and other settings.

The milling drill is a versatile tool that can be used for a variety of tasks. It can be used to create holes for screws, bolts, and other fasteners, as well as to create slots for hinges and other components. It can also be used to create grooves and other features in a workpiece. The milling drill is also used to create intricate shapes and patterns in a workpiece, such as those used in decorative woodworking.

Whats the difference between milling and drilling?

Milling and drilling are two common machining processes used in manufacturing. Milling is a machining process that uses a rotating cutting tool to remove material from a workpiece. The cutting tool is moved in a linear direction across the surface of the workpiece, removing material in the form of small chips. Milling can be used to create a variety of shapes and features on a workpiece, including slots, pockets, and contours.

Drilling is a machining process that uses a rotating cutting tool to create a hole in a workpiece. The cutting tool is moved in a linear direction into the workpiece, creating a hole with a diameter equal to the diameter of the cutting tool. Drilling can be used to create a variety of hole sizes and shapes, including straight, tapered, and countersunk holes.

The main difference between milling and drilling is the type of cutting tool used and the direction of the cutting tool relative to the workpiece.

Whats the difference between a milling machine and a drill press?

The main difference between a milling machine and a drill press is the type of work they are used for. A milling machine is a versatile tool used for shaping and cutting metal and other materials, while a drill press is mainly used for drilling holes into materials.

Milling machines are typically larger and more complex than drill presses, and are capable of performing a variety of operations, including cutting, drilling, shaping, and grinding. They are also capable of performing more complex operations such as contouring, slotting, and threading. Milling machines are usually used for larger projects and require more setup time than a drill press.

Drill presses, on the other hand, are mainly used for drilling holes into materials. They are typically smaller and simpler than milling machines, and are not capable of performing complex operations. Drill presses are usually used for smaller projects and require less setup time than a milling machine.

In summary, the main difference between a milling machine and a drill press is the type of work they are used for.

Can I mill with a drill press?

No, you cannot mill with a drill press. A drill press is designed to drill holes, while a milling machine is designed to cut and shape material. A drill press is limited in its ability to shape material, as it only moves up and down in a single axis. A milling machine, on the other hand, can move in multiple axes and is capable of cutting and shaping material in a variety of ways. Additionally, a milling machine is equipped with a spindle that rotates at high speeds, allowing it to cut and shape material more quickly and accurately than a drill press.

What is the difference between milling and grinding?

Milling and grinding are two common machining processes performed in the manufacturing industry. They both involve the removal of material from a workpiece, and they both support a wide variety of materials, such as metal, wood, plastics, and ceramics. The primary difference between the two processes is the manner in which the material is removed.

Milling is a cutting process that uses a milling cutter to remove material from the surface of a workpiece. The milling cutter is a rotary cutting tool with multiple cutting points. As the milling cutter rotates, the cutting points on the tool remove material from the workpiece, creating a flat surface. Milling can be used to create a variety of features on a workpiece, including slots, pockets, and grooves.

Grinding is an abrasive machining process that uses a grinding wheel as the cutting tool. A grinding wheel is a wheel composed of an abrasive compound and used for various grinding (abrasive cutting) and abrasive machining operations.

What is a mill drill ESL?

A mill drill ESL is a type of machine tool that combines the functions of a milling machine and a drill press. It is typically used for drilling, reaming, counterboring, and tapping operations, as well as for milling operations such as slotting, profiling, and contouring. It is designed to be used in a variety of applications, from light-duty home workshops to heavy-duty industrial production.

The mill drill ESL is a versatile machine that can be used for a variety of operations. It is designed to be used in a variety of applications, from light-duty home workshops to heavy-duty industrial production. It is capable of drilling, reaming, counterboring, and tapping operations, as well as milling operations such as slotting, profiling, and contouring. It is also capable of performing other operations such as boring, facing, and threading.

What is the difference between turning and milling?

Milling and turning are two common machining processes used in the manufacturing industry. Both processes involve the removal of material from a workpiece, but the manner in which the material is removed and the results that are produced are different.

Milling is a machining process that uses a rotating multi-point cutting tool to remove material from the surface of a workpiece. The cutting tool is fed into the workpiece in a linear direction, and the material is removed in the form of chips. Milling is used to produce flat surfaces, grooves, slots, and complex shapes. It is also used to produce parts with a high degree of accuracy and repeatability.

Turning is a machining process that uses a single-point cutting tool to remove material from the surface of a rotating workpiece. The cutting tool is fed into the workpiece in a radial direction, and the material is removed in the form of chips. Turning is used to produce cylindrical parts with a high degree of accuracy and repeatability.

What is the difference between milling and boring?

Milling and boring are two different machining processes used in the manufacturing industry. Milling is a machining process that uses a rotating cutting tool to remove material from a workpiece. The cutting tool is moved in a linear direction across the surface of the workpiece, removing material in the form of small chips. Milling can be used to create a variety of shapes and features on a workpiece, including flat surfaces, contoured surfaces, grooves, slots, and complex 3D shapes.

Boring, on the other hand, is a machining process that is used to enlarge or finish the internal surface of a workpiece. Boring is typically used to create a cylindrical hole in a workpiece, but can also be used to create other shapes. The boring tool is inserted into the workpiece and rotated to remove material from the internal surface. Boring is typically used to create precise, smooth, and uniform surfaces on the internal surface of a workpiece.

What is the difference between a lathe and a milling machine?

A lathe and a milling machine are both used in manufacturing and fabrication, but they have very different functions. A lathe is a machine tool that rotates a workpiece about an axis of rotation to perform various operations such as cutting, sanding, knurling, drilling, or deformation. It is used to shape a variety of materials, including metal, wood, and plastic. A milling machine is a machine tool used to machine solid materials. It uses a rotating cutting tool to remove material from the workpiece in a variety of directions. It can be used to drill, bore, cut gears, and produce slots.

The main difference between a lathe and a milling machine is the way in which they cut material. A lathe uses a stationary cutting tool to shape the material, while a milling machine uses a rotating cutting tool to shape the material. Lathes are generally used to shape cylindrical objects, while milling machines are used to shape flat surfaces.