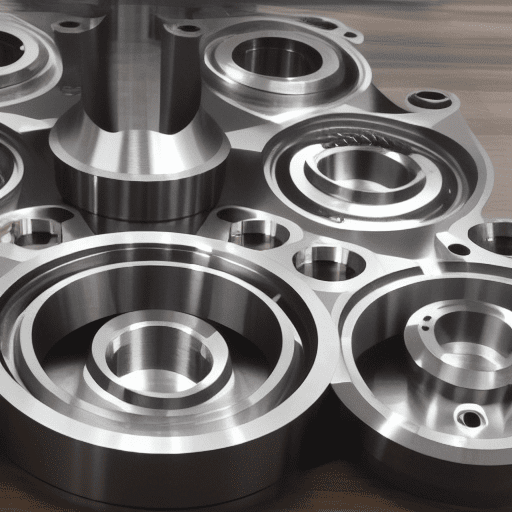

Machined parts are components that have been created through a machining process. Machining is a manufacturing process that involves the use of specialized tools and machines to shape and cut materials into desired shapes and sizes. Machined parts can be made from a variety of materials, including metals, plastics, and composites. The machining process typically involves the use of a cutting tool, such as a drill, lathe, milling machine, or router, to remove material from the workpiece. The cutting tool is guided by a computer numerical control (CNC) system, which is programmed with the desired shape and size of the part. The machined part is then finished with additional processes such as grinding, polishing, and heat treating. Machined parts are used in a variety of industries, including automotive, aerospace, medical, and consumer products. They are used to create components for products such as engines, medical implants, and consumer electronics. Machined parts are also used in the construction of buildings and other structures.

What is the purpose of machining?

The purpose of machining is to shape and finish a workpiece by removing excess material in order to create a desired shape and size. Machining is used in a variety of industries, including automotive, aerospace, medical, and manufacturing. It is used to create parts for machines, tools, and other products. Machining is also used to create components for products such as engines, turbines, and other mechanical systems.

Machining is a process that involves cutting, shaping, and forming a workpiece using a variety of tools and machines. It is a subtractive manufacturing process, meaning that material is removed from the workpiece in order to create the desired shape and size. Machining can be done manually or with the help of computer numerical control (CNC) machines.

The purpose of machining is to create parts and components with precise dimensions and shapes. It is used to create parts for machines, tools, and other products. It is also used to create components for products such as engines, turbines, and other mechanical systems.

What is sheet metal forming machine?

A sheet metal forming machine is a type of machine used to shape and form sheet metal into desired shapes and sizes. It is typically used in the manufacturing of products such as car bodies, aircraft wings, and other metal components. Sheet metal forming machines use a variety of tools and techniques to shape the metal, including cutting, bending, rolling, and stamping. The type of machine used depends on the desired shape and size of the finished product. Sheet metal forming machines can be manual, semi-automatic, or fully automated. Manual machines require the operator to manually move the sheet metal through the machine, while semi-automatic and fully automated machines use a variety of sensors and motors to move the sheet metal through the machine. Sheet metal forming machines are used in a variety of industries, including automotive, aerospace, and construction.

Why do we need advanced machining processes?

Advanced machining processes are necessary in order to produce parts and components with greater precision and accuracy than what is achievable with traditional machining methods. Advanced machining processes allow for the production of parts with complex geometries, intricate details, and tight tolerances that are not possible with traditional machining methods. Advanced machining processes also allow for the production of parts with improved surface finishes, which can be beneficial for certain applications. Additionally, advanced machining processes can be used to produce parts with improved strength and durability, which can be beneficial for certain applications. Finally, advanced machining processes can be used to produce parts with improved dimensional stability, which can be beneficial for certain applications. All of these benefits make advanced machining processes an essential part of modern manufacturing.

What does CNC machining mean?

CNC machining is a manufacturing process that uses computer numerical control (CNC) machines to shape and cut materials into a desired shape or size. CNC machining is a subtractive manufacturing process, meaning that material is removed from a solid block or sheet to create the desired shape. CNC machining is used to create parts with complex shapes and high precision. It is used in a variety of industries, including aerospace, automotive, medical, and consumer products.

CNC machining is a process that involves the use of computer-controlled machines to shape and cut materials into a desired shape or size. The machines are programmed with a set of instructions that tell them how to move and cut the material. The instructions are written in a computer language called G-code. The machines are then able to move and cut the material according to the instructions.

CNC machining is a very precise process, and it is used to create parts with complex shapes and high precision. It is used in a variety of industries, including aerospace, automotive, medical, and consumer products.

Is machining a manufacturing process?

Yes, machining is a manufacturing process. Machining is a process in which material is removed from a workpiece to create a desired shape or finish. It is a subtractive process, meaning that material is removed from the workpiece to achieve the desired shape or finish. Machining is used to create parts for a variety of industries, including automotive, aerospace, medical, and consumer products.

Machining is a versatile process that can be used to create a wide variety of shapes and finishes. It can be used to create parts with complex geometries, such as those used in aerospace and medical applications. It can also be used to create parts with a high degree of accuracy and repeatability.

Machining is typically done using a variety of tools, such as lathes, milling machines, and drill presses. These tools are used to cut, shape, and finish the workpiece. The tools used in machining are typically powered by electricity, compressed air, or hydraulics.

What is metal machining?

Metal machining is a process of cutting and shaping metal materials into desired shapes and sizes. It is a manufacturing process that involves the use of specialized tools and machines to remove material from a workpiece in order to create a desired shape or size. The process of metal machining can be divided into two main categories: subtractive machining and additive machining.

Subtractive machining is the process of removing material from a workpiece in order to create a desired shape or size. This is done by using tools such as drills, milling machines, lathes, and grinders. These tools are used to cut away material from the workpiece in order to create the desired shape or size.

Additive machining is the process of adding material to a workpiece in order to create a desired shape or size. This is done by using tools such as welding, brazing, soldering, and casting. These tools are used to add material to the workpiece in order to create the desired shape or size.

How important is machining in manufacturing?

Machining is an essential part of the manufacturing process. It is a process that involves cutting, shaping, and forming materials to create a desired product. Machining is used to create parts and components for a variety of industries, including automotive, aerospace, medical, and consumer products.

The importance of machining in manufacturing is due to its ability to create precise and accurate parts and components. Machining can be used to create parts with tight tolerances and intricate shapes. This is especially important in industries such as aerospace, where parts must be able to withstand extreme temperatures and pressures. Machining also allows for the creation of complex parts that would be difficult or impossible to create using other methods.

In addition to its precision and accuracy, machining is also important because it is a relatively fast process. This is especially important in industries such as automotive, where parts must be produced quickly and efficiently. Machining also allows for the production of parts in large quantities, which is important for industries such as consumer products.