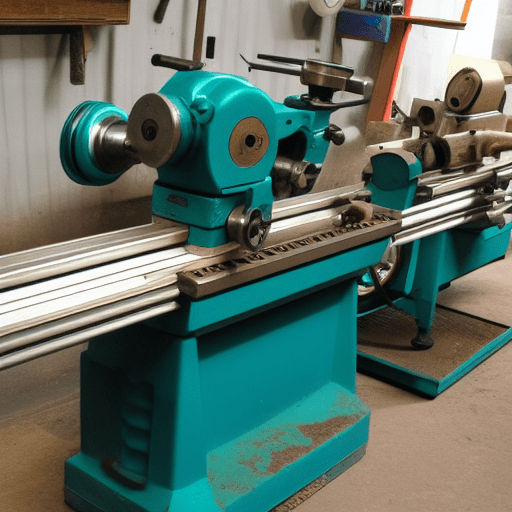

A lathe is a machine tool used for shaping metal, wood, or other materials by cutting, sanding, knurling, drilling, deformation, facing, and turning with tools that are applied to the workpiece to create an object with symmetry about an axis of rotation. While a lathe is a versatile tool that can be used to create a variety of shapes and objects, there are certain tasks that it cannot do.

One of the main limitations of a lathe is that it cannot be used to cut internal threads. This is because the cutting tool must be able to reach the internal thread in order to cut it, and the cutting tool on a lathe is limited to the outside of the workpiece. Additionally, a lathe cannot be used to cut complex shapes, such as those with curved surfaces or intricate details. This is because the cutting tool is limited to a single axis of rotation, and therefore cannot reach all of the necessary points on the workpiece.

Another limitation of a lathe is that it cannot be used to cut materials that are too hard or too thick. This is because the cutting tool is limited in its ability to cut through the material, and if the material is too hard or too thick, it will not be able to cut through it. Additionally, a lathe cannot be used to cut materials that are too soft, as the cutting tool will not be able to hold the material in place while it is being cut.

Finally, a lathe cannot be used to cut materials that are too small. This is because the cutting tool is limited in its ability to reach the small parts of the workpiece, and therefore will not be able to cut them. Additionally, a lathe cannot be used to cut materials that are too large, as the cutting tool will not be able to reach the entire workpiece.

What are the limitations of a lathe?

A lathe is a machine tool used for shaping metal, wood, or other materials by cutting, sanding, knurling, drilling, deformation, facing, and turning. It is one of the most versatile tools in a machinist’s arsenal, but it does have some limitations.

One of the main limitations of a lathe is its size. Lathes are typically limited to the size of the material that can be held in the chuck. This means that larger pieces of material must be cut down to size before they can be machined. Additionally, the size of the lathe itself can limit the size of the parts that can be machined.

Another limitation of a lathe is its accuracy. While a lathe can produce parts with a high degree of accuracy, it is limited by the accuracy of the cutting tools used. If the cutting tools are not sharp or are not properly aligned, the parts produced will not be as accurate as they could be.

What are the advantages of using a lathe machine?

A lathe machine is a versatile tool used in a variety of industries for a variety of purposes. It is used to shape and form materials such as wood, metal, and plastic into a desired shape. The advantages of using a lathe machine include:

1. Precision: Lathe machines are capable of producing highly precise and accurate parts. This is due to the fact that the cutting tool is held in a fixed position and the material is rotated against it. This allows for a high degree of accuracy and repeatability.

2. Versatility: Lathe machines can be used to produce a wide variety of shapes and sizes. This makes them ideal for producing complex parts with intricate details.

3. Efficiency: Lathe machines are capable of producing parts quickly and efficiently. This is due to the fact that the cutting tool is held in a fixed position and the material is rotated against it. This allows for a high degree of accuracy and repeatability.

What materials can a lathe cut?

A lathe is a machine tool used to shape materials such as metal, wood, plastic, or stone. It is used to cut, shape, and form materials into a variety of shapes and sizes. Lathes are used in a variety of industries, including automotive, aerospace, and medical.

Lathes can cut a variety of materials, including metals, plastics, wood, and stone. Metals are the most common material cut on a lathe, and they can be cut into a variety of shapes and sizes. Common metals that can be cut on a lathe include aluminum, brass, copper, steel, and titanium. Plastics can also be cut on a lathe, and they are often used to create custom parts for a variety of applications. Common plastics that can be cut on a lathe include acrylic, polycarbonate, and polyethylene.

Wood is another material that can be cut on a lathe. Wood is often used to create custom furniture, musical instruments, and other decorative items.

What are the disadvantages of machining?

Machining is a process that involves cutting and shaping materials to create a desired product. While it is a very useful and versatile process, there are some disadvantages associated with it.

One of the main disadvantages of machining is the cost. Machining is a labor-intensive process that requires specialized tools and equipment, which can be expensive to purchase and maintain. Additionally, the cost of labor for machining can be high, as it requires skilled workers to operate the machines.

Another disadvantage of machining is the time it takes to complete a job. Machining is a slow process, and it can take a long time to complete a job, depending on the complexity of the product. This can be a problem for businesses that need to produce products quickly.

Machining also produces a lot of waste material. This is because the process involves cutting away material to create the desired shape, which results in a lot of scrap material. This can be costly for businesses, as they have to pay for the disposal of the waste material.