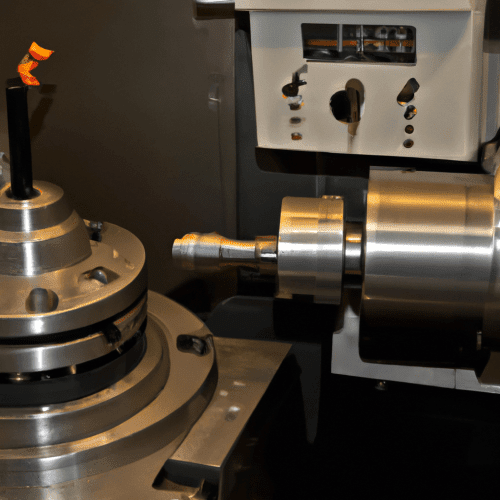

A CNC (Computer Numerical Control) miller is a type of machining tool used to shape and cut materials such as metal, wood, and plastic. It is a type of automated machine that is programmed to move in a specific way to create a desired shape or cut. The CNC miller is typically used in industrial settings to create parts for machines, tools, and other products.

The CNC miller is programmed with a computer-aided design (CAD) program, which is used to create a 3D model of the desired shape or cut. The CNC miller then reads the CAD program and uses its motors to move the cutting tool in the desired direction and at the desired speed. The cutting tool is usually a drill bit, end mill, or router bit, and is used to cut away material from the workpiece. The CNC miller can also be programmed to perform other operations such as drilling, tapping, and reaming.

The CNC miller is a versatile tool that can be used to create a variety of shapes and cuts. It is used in a variety of industries, including automotive, aerospace, medical, and electronics. It is also used in the production of furniture, toys, and other consumer products. The CNC miller is a powerful tool that can be used to create complex shapes and cuts with precision and accuracy.

Why is CNC milling used?

CNC (Computer Numerical Control) milling is a manufacturing process that uses computer-controlled cutting tools to remove material from a workpiece in order to create a custom-designed part or product. CNC milling is used for a variety of applications, including the production of complex parts with intricate contours, as well as the production of components with precise dimensions and tolerances. CNC milling is also used to create complex shapes and features, such as slots, grooves, and threads.

CNC milling is a popular choice for many manufacturers due to its accuracy, repeatability, and cost-effectiveness. CNC milling machines are able to produce parts with tight tolerances and intricate details that would be difficult or impossible to produce with traditional machining methods. CNC milling also offers a high degree of automation, allowing for the production of large quantities of parts with minimal operator intervention. Additionally, CNC milling machines are capable of producing parts with a wide range of materials, including metals, plastics, and composites.

What does a CNC machine do?

A CNC (Computer Numerical Control) machine is a type of automated machine tool that uses computer programs to control the movement and operation of the machine. CNC machines are used to produce high-precision parts with complex shapes in a variety of materials. The machine is programmed with a series of instructions that tell it how to move and operate. The instructions are typically written in a computer language called G-code.

CNC machines are used in a variety of industries, including aerospace, automotive, medical, and consumer products. They are used to produce parts for a wide range of products, from medical implants to aircraft components. CNC machines are also used to produce molds and dies for injection molding and die casting.

CNC machines are highly accurate and can produce parts with tight tolerances. They are also capable of producing complex shapes and intricate details. CNC machines are also very efficient, as they can produce parts quickly and with minimal waste.

CNC machines are typically operated by a computer program, which is written in a computer language such as G-code.

How do I become a CNC Miller?

Becoming a CNC Miller requires a combination of education, experience, and technical skills. To become a CNC Miller, you should first obtain a high school diploma or equivalent. After that, you should consider enrolling in a post-secondary program in machining, manufacturing, or a related field. This will provide you with the necessary technical knowledge and skills to become a CNC Miller. Additionally, you should consider gaining experience in the field by working as an apprentice or intern in a machine shop. This will give you the opportunity to learn the trade from experienced professionals and gain hands-on experience with CNC machines.

Once you have the necessary education and experience, you should consider obtaining certification in CNC machining. This will demonstrate to employers that you have the necessary skills and knowledge to work as a CNC Miller. Additionally, you should consider joining a professional organization such as the National Institute for Metalworking Skills (NIMS). This will provide you with access to resources and networking opportunities that can help you advance your career.

How much can a CNC business make?

The amount of money a CNC business can make depends on a variety of factors, including the size of the business, the type of services offered, the number of clients, and the cost of materials and labor. Generally speaking, a CNC business can make anywhere from a few thousand dollars to millions of dollars in revenue each year.

The size of the business is a major factor in determining how much money a CNC business can make. Smaller businesses may only make a few thousand dollars in revenue each year, while larger businesses may make millions of dollars in revenue. The type of services offered by the business is also important. If the business specializes in high-end services, such as custom machining or prototyping, it can charge higher rates and make more money. The number of clients is also important, as more clients means more potential revenue.

The cost of materials and labor is also a major factor in determining how much money a CNC business can make.

What can you make on a CNC lathe?

A CNC lathe is a computer-controlled machine tool used for machining metal parts. It is capable of producing a wide variety of shapes and sizes, from simple to complex. It is used in a variety of industries, including automotive, aerospace, medical, and electronics.

The most common type of CNC lathe is the turning center, which is used to produce cylindrical parts. It is capable of producing parts with a variety of shapes, including round, hexagonal, square, and rectangular. It can also produce parts with complex contours, such as threads, grooves, and tapers.

The CNC lathe can be used to produce a variety of parts, including shafts, pins, bushings, and other components. It can also be used to produce complex parts, such as gears, sprockets, and pulleys. It can also be used to produce parts with intricate details, such as intricate patterns and engravings.

What do machine shops make?

Machine shops are manufacturing facilities that specialize in the machining of metal parts. They use a variety of tools and machines to cut, shape, and form metal into the desired shape or size. Machine shops typically use lathes, milling machines, drill presses, and other specialized equipment to create parts for a variety of industries, including automotive, aerospace, medical, and industrial.

The parts created by machine shops can range from simple components such as screws and bolts to complex parts such as engine blocks and turbine blades. Machine shops can also create custom parts for specific applications, such as medical implants or aerospace components.

In addition to machining metal parts, machine shops can also provide services such as heat treating, welding, and finishing. Heat treating is a process used to strengthen metal parts by heating and cooling them in a controlled environment. Welding is a process used to join two pieces of metal together, while finishing is a process used to give metal parts a smooth, polished look.