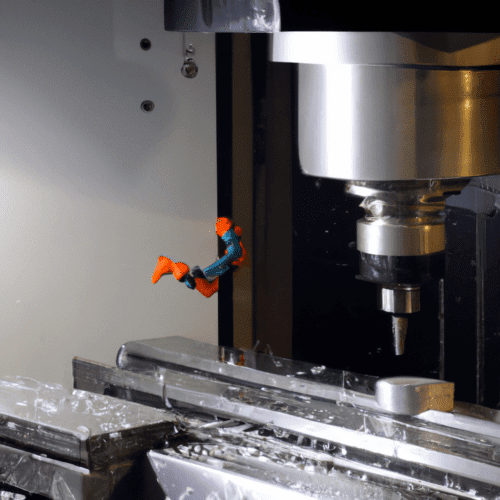

CNC milling is a method of machining parts which utilizes a computer-controlled cutting tool, typically a spinning end mill, to remove material from a workpiece. CNC milling is an effective and versatile manufacturing process which is widely used to produce precision components and parts of varying complexity and size. The main benefit of CNC milling is its high degree of accuracy and repeatability. By using a computer-controlled cutting tool to precisely move across a workpiece, CNC milling machines can produce highly accurate components with tight dimensional tolerances. This makes CNC milling especially suitable for producing parts with complex shapes and intricate details. CNC milling is also very versatile, as it can produce parts of varying complexity and size, from small components to large industrial parts.

The process can be used for a variety of materials, including aluminum, steel, stainless steel, brass, and plastic. Additionally, CNC milling machines are capable of performing a variety of machining operations, such as drilling, tapping, countersinking, and pocketing. Overall, CNC milling is an efficient and reliable way to produce precision parts of varying complexity and size. Its high degree of accuracy and repeatability, combined with its versatility and range of capabilities, make it a popular manufacturing process for a wide variety of industries.

Benefits of CNC Milling for Industrial Manufacturing

CNC (Computer Numerical Control) milling has become an invaluable tool for industrial manufacturing. This technology offers a variety of benefits for the production process, including increased precision, higher accuracy, faster production times, and improved product quality. CNC milling uses a computer-controlled machine to cut and shape material into the desired shape. This is done by using a cutting tool, which is operated by a CNC controller. The cutting tool is moved through the material, guided by the computer program. This allows for precise and accurate cuts. The cutting tool also moves in multiple directions, which increases the speed of production. CNC milling also offers increased accuracy and precision, since the cutting tool is guided by the computer program. This ensures that a product is produced with consistent dimensions and accuracy.

CNC milling also eliminates the need for manual labor, as the cutting tool is controlled by the computer program. This reduces the risk of human error, which could lead to an inaccurate product. CNC milling also leads to faster production times. Because the cutting tool is guided by the computer program, the cutting process can be done faster than with manual labor. This means that more products can be produced in a shorter amount of time. This helps to reduce production costs and improve efficiency. Finally, CNC milling leads to improved product quality. Because the cutting tool is guided by the computer program, the produced parts are more consistent in size, shape, and accuracy. This leads to a higher quality product that is more reliable and durable. Overall, CNC milling is an invaluable tool for industrial manufacturing. This technology offers increased precision, accuracy, faster production times, and improved product quality.

Exploring the Advantages of CNC Milling Over Traditional Machining

CNC (Computer Numerical Control) milling is a modern machining process that has revolutionized the manufacturing industry. It has become one of the most popular machining methods in the industry due to its many advantages over traditional machining. One of the primary benefits of CNC milling is its ability to produce parts with high precision and accuracy. CNC milling machines are programmed using computer software, meaning that every part produced will be exactly the same as the one before it. This level of precision is not achievable with traditional machining, as it is more difficult to control the exact movements of a cutting tool. Another advantage is the time savings associated with CNC milling. With traditional machining, a large amount of time is spent setting up the machine and moving it from one part to the next.

CNC machines, on the other hand, can be programmed to produce multiple parts automatically, eliminating the need for manual set up and saving time. The cost savings associated with CNC milling are also significant. CNC machines are able to produce parts quickly and accurately, meaning fewer materials are wasted during production. This, combined with the speed of CNC milling, allows manufacturers to produce parts at a lower cost. Finally, CNC milling is much safer than traditional machining. CNC machines are equipped with safety features such as automatic shut-off and emergency stops, reducing the risk of injury to operators. In conclusion, CNC milling has many advantages over traditional machining. It is able to produce parts with high precision and accuracy, save time, reduce costs, and increase safety. For these reasons, it has become one of the most popular machining methods in the industry.

How to Choose the Right CNC Milling Machine for Your Needs

Choosing the right CNC milling machine for any project is an important decision. With so many options available, it can be difficult to decide which machine is right for you. Here are some factors to consider when selecting a CNC milling machine.

1. Budget: What is your budget for the machine? Consider both the cost of the machine itself and any associated costs, such as software and training.

2. Space: How much space do you have to work with? CNC milling machines range in size from small desktop machines to large industrial models. Make sure the machine you select will fit in the space you have available.

3. Features: What features are important to you? CNC milling machines come with a variety of features, such as automatic tool changing and built-in safety features. Consider which features are most important to you and make sure the machine you choose has them.

4. Materials: What types of materials will you be working with? Different materials require different tools and processes. Make sure the machine you choose is capable of working with the materials you need.

5. Support: Does the manufacturer provide good support? Make sure the manufacturer you select provides good customer service and technical support. By considering these factors, you can make sure you select the right CNC milling machine for your needs.

Understanding the Different Types of CNC Milling Tools and Their Uses

CNC milling is a precise process that utilizes computer numerical control to shape and cut materials with precision. It is a popular choice for machining operations due to its ability to produce intricate parts with high levels of accuracy. CNC milling tools are the key components that make CNC milling possible. There are many different types of CNC milling tools available, each with their own unique purpose and application. End Mills are the most common type of CNC milling tool. They are typically used for cutting and shaping the material in the form of slots, pockets, and contours. They come in two main varieties: the “roughing” end mill, which is used for rapid material removal, and the “finishing” end mill, which is used for more precise cutting and shaping.

End mills are available in a variety of sizes and shapes, and can be used with both manual and CNC milling machines. Drills are another type of CNC milling tool. They are primarily used for creating holes in a material, but can also be used for cutting other shapes. Drills come in a variety of sizes and shapes, and are available with both standard and specialized cutting tips. Reamers are a type of CNC milling tool used for finishing the internal surfaces of holes. They are available in a variety of shapes and sizes, and can be used with both manual and CNC milling machines. Counterbores and Countersinks are CNC milling tools used for creating recesses in a material. They are available in a variety of sizes and shapes, and can be used for both manual and CNC milling machines. Taps are a type of CNC milling tool used for creating internal threads in a material. They come in a variety of sizes and shapes, and can be used with both manual and CNC milling machines.

Finally, Form Tools are a type of CNC milling tool used for creating complex shapes and profiles in a material. They are available in a variety of sizes and shapes, and can be used with both manual and CNC milling machines. CNC milling tools are essential for any machining operation. Each type of tool has its own unique purpose and application, and can be used to create intricate parts with high levels of accuracy. Knowing which type of tool to use for a particular job is key

The Benefits of Automation in CNC Milling for New Product Development

Automation in CNC milling is becoming increasingly popular in new product development due to its many benefits. CNC (Computer Numerical Control) milling is a process which utilizes computer software to control the movement of a cutting tool, allowing for precision machining of complex shapes and geometries. Automation of this process can significantly reduce the time and cost associated with creating products, as well as the labor involved. Automation of CNC milling can provide faster and more accurate results than manual machining. This is due to the ability of the computer to precisely control the cutting tool’s speed and depth of cut, as well as the angle of approach, which can be adjusted as needed for different materials and geometries. Automated CNC milling also eliminates the need for manual inspection of each part as part of the production process, as the computer is able to detect and correct any errors in the cutting process.

In addition to the improved accuracy and speed, automation in CNC milling also makes it easier to modify existing designs. Since the programming is done by a computer, it is easy to modify the design or make minor adjustments without having to start from scratch. This can save time and money, as it eliminates the need to make costly and time-consuming changes to the original design. Finally, automation in CNC milling can also improve safety by eliminating the need for manual handling of the cutting tools. This reduces the chances of injury and increases the overall safety of the work environment. Overall, automation in CNC milling can provide a wide range of benefits for new product development, including improved accuracy and speed, reduced labor costs, improved safety, and increased design flexibility. Automation of CNC milling can help make production processes more efficient and cost-effective, leading to faster development times and higher quality products.