A CNC (Computer Numerical Control) lathe is a type of machine tool that uses computer-controlled processes to shape and cut materials. It is a specialized type of lathe that uses computer-controlled motors to move the cutting tool and workpiece in precise increments. CNC lathes are used to produce a wide variety of parts, from small precision components to large, complex shapes. The CNC lathe is capable of producing parts with high accuracy and repeatability, and can be used to produce parts with complex geometries. CNC lathes are used in a variety of industries, including automotive, aerospace, medical, and electronics.

CNC lathes are typically programmed using a computer-aided design (CAD) program, which allows the user to create a 3D model of the part to be machined. The CAD program then generates a set of instructions, known as G-code, which is used to control the CNC lathe. The G-code is used to control the speed, direction, and depth of the cutting tool, as well as the position of the workpiece. The CNC lathe is capable of producing parts with high accuracy and repeatability, and can be used to produce parts with complex geometries.

CNC lathes are used in a variety of industries, including automotive, aerospace, medical, and electronics. They are used to produce a wide variety of parts, from small precision components to large, complex shapes. CNC lathes are capable of producing parts with high accuracy and repeatability, and can be used to produce parts with complex geometries.

What is a CNC lathe and how does it work?

A CNC lathe is a computer numerical control (CNC) machine tool used for metalworking. It is a type of lathe that uses computer-controlled motors to rotate the workpiece and cutting tools to produce precise parts with complex shapes. The CNC lathe is a versatile machine tool that can be used to produce a variety of parts, from simple to complex.

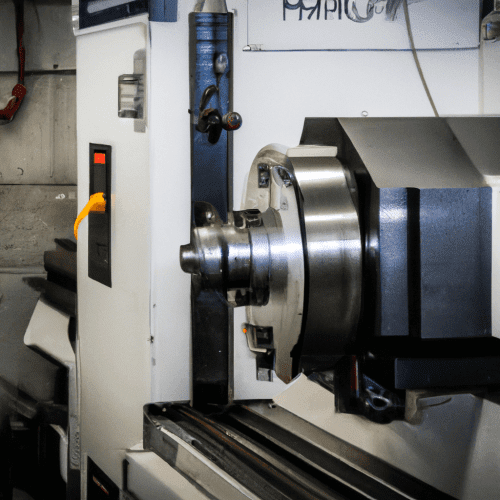

The CNC lathe is composed of several components, including a spindle, a bed, a tailstock, a tool holder, and a control system. The spindle is the rotating part of the machine that holds the workpiece and cutting tools. The bed is the base of the machine that supports the spindle and other components. The tailstock is a movable support that holds the workpiece in place while it is being machined. The tool holder is a device that holds the cutting tools in place. The control system is the computer that controls the machine’s movements and operations.

What can a CNC lathe make?

A CNC (Computer Numerical Control) lathe is a machine tool that uses computer-controlled processes to shape and cut materials into a desired shape. It is a type of metalworking lathe that is used to create parts with complex shapes and features. CNC lathes are used in a variety of industries, including automotive, aerospace, medical, and electronics.

CNC lathes are capable of producing a wide range of parts, from simple to complex. They can be used to create parts with intricate details, such as threads, grooves, and other features. CNC lathes can also be used to create parts with multiple features, such as holes, slots, and other shapes. Additionally, CNC lathes can be used to create parts with a variety of materials, including metals, plastics, and composites.

CNC lathes are also capable of producing parts with a high degree of accuracy and repeatability. This is due to the fact that the machine is programmed with precise instructions, which are then followed by the machine to create the desired part.

What is the difference between a lathe and a CNC lathe?

A lathe is a machine tool used to shape a variety of materials, such as metal, wood, and plastic, by rotating a workpiece against a cutting tool. It is used to create cylindrical parts, as well as other shapes, by cutting, drilling, and grinding. Lathes are used in a variety of industries, including automotive, aerospace, and medical.

A CNC lathe is a computer numerical control (CNC) machine tool that uses a computer to control the motion of the cutting tool. It is used to produce parts with complex shapes and high precision. CNC lathes are used in a variety of industries, including automotive, aerospace, and medical.

The main difference between a lathe and a CNC lathe is that a CNC lathe is automated and can be programmed to produce parts with complex shapes and high precision. A CNC lathe is also able to produce parts with a higher degree of accuracy than a manual lathe.

What is a CNC turning lathe?

A CNC (Computer Numerical Control) turning lathe is a type of machine tool used for producing precision parts from a variety of materials. It is a specialized form of a lathe, which is a machine tool used for shaping and cutting metal and other materials. The CNC turning lathe is a computer-controlled version of the traditional lathe, and is used to produce parts with a high degree of accuracy and repeatability.

The CNC turning lathe is composed of several components, including a spindle, a bed, a tailstock, and a tool holder. The spindle is the rotating part of the machine, and is used to hold and rotate the workpiece. The bed is the base of the machine, and is used to support the spindle and the tailstock. The tailstock is a movable part of the machine, and is used to hold the cutting tool. The tool holder is used to hold the cutting tool in place.

What does CNC stand for?

CNC stands for Computer Numerical Control. It is a manufacturing process that uses computer-controlled machines to cut and shape materials such as metal, wood, and plastic. CNC machines are programmed with a set of instructions that tell the machine what to do and how to do it. The instructions are written in a computer language called G-code, which is a language specifically designed for CNC machines. CNC machines are used in a variety of industries, including aerospace, automotive, and medical device manufacturing. They are used to create precision parts and components with high accuracy and repeatability. CNC machines are also used in the production of furniture, musical instruments, and other consumer goods. CNC machines are highly automated and require minimal human intervention, making them ideal for mass production.

How does a lathe work?

A lathe is a machine tool used to shape a variety of materials, such as metal, wood, and plastic, by rotating a workpiece against a cutting tool. The cutting tool is typically held in a tool holder that is mounted on the headstock of the lathe. The headstock is the part of the lathe that is mounted on the bed and contains the motor that drives the spindle. The spindle is the part of the lathe that rotates the workpiece. The tailstock is the part of the lathe that is mounted on the bed and holds the cutting tool.

The cutting tool is typically held in a tool holder that is mounted on the headstock of the lathe. The tool holder is adjustable so that the cutting tool can be positioned at different angles and depths. The cutting tool is then moved along the length of the workpiece as the spindle rotates the workpiece. The cutting tool is used to remove material from the workpiece in order to shape it into the desired shape.

What is the difference between CNC lathe and CNC milling machine?

The primary difference between a CNC lathe and a CNC milling machine is the way in which they cut materials. A CNC lathe uses a rotating cutting tool to shape the material, while a CNC milling machine uses a stationary cutting tool to shape the material.

CNC lathes are typically used to produce cylindrical parts, such as shafts, spindles, and bushings. The cutting tool is fed into the rotating material, and the cutting tool is moved along the material’s surface to shape it. CNC lathes are capable of producing complex shapes and intricate details.

CNC milling machines, on the other hand, are used to produce flat surfaces, slots, and other features. The cutting tool is fed into the stationary material, and the cutting tool is moved along the material’s surface to shape it. CNC milling machines are capable of producing complex shapes and intricate details.

Which type of machine is a CNC lathe machine?

A CNC (Computer Numerical Control) lathe machine is a type of automated machine tool that is used to shape and form metal and other materials. It is a specialized type of lathe that uses computer-controlled motors and other components to precisely control the cutting and shaping of the material. The CNC lathe is programmed with a set of instructions that tell the machine how to move and shape the material. The instructions are typically written in a computer language such as G-code or CNC programming language.

The CNC lathe is used to produce a variety of parts, including complex shapes and intricate details. It is used in a variety of industries, including automotive, aerospace, medical, and electronics. The CNC lathe is capable of producing parts with high accuracy and repeatability, and can be used to produce parts with complex geometries.

The CNC lathe is typically composed of several components, including a spindle, a bed, a tool holder, and a control system. The spindle is the rotating part of the machine that holds the cutting tool.