A CNC turner is a type of machine tool that is used to shape metal and other materials into a desired shape or size. It is a type of computer numerical control (CNC) machine, which means that it is operated by a computer program that is programmed to control the machine’s movements. The CNC turner is used to create parts with a high degree of accuracy and repeatability. It is capable of producing parts with complex shapes and intricate details.

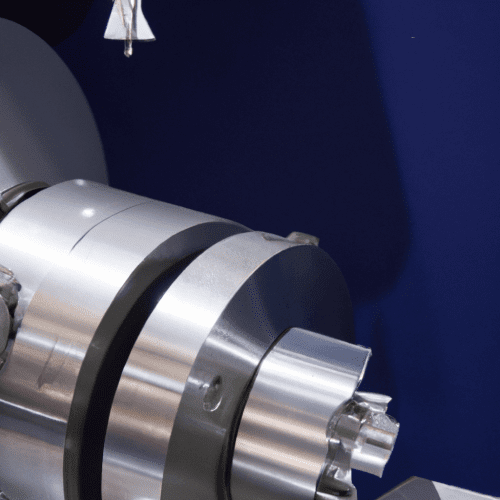

The CNC turner is composed of several components, including a spindle, a tool holder, a tool changer, and a workpiece holder. The spindle is the rotating part of the machine that holds the cutting tool. The tool holder is used to hold the cutting tool in place. The tool changer is used to change the cutting tool when needed. The workpiece holder is used to hold the workpiece in place while the cutting tool is used to shape it.

The CNC turner is operated by a computer program that is programmed to control the machine’s movements. The program is used to control the speed and direction of the spindle, the feed rate of the cutting tool, and the depth of the cut. The program also controls the tool changer and the workpiece holder.

The CNC turner is used to create parts with a high degree of accuracy and repeatability. It is capable of producing parts with complex shapes and intricate details. It is used in a variety of industries, including automotive, aerospace, medical, and electronics.

What is a CNC turning lathe?

A CNC (Computer Numerical Control) turning lathe is a type of machine tool used for producing precision parts from a variety of materials. It is a specialized type of lathe that uses computer-controlled commands to rotate a workpiece and cut it into a desired shape. The CNC turning lathe is capable of producing complex shapes and intricate details with a high degree of accuracy and repeatability. It is used in a variety of industries, including automotive, aerospace, medical, and electronics.

The CNC turning lathe consists of a spindle, a tool holder, and a bed. The spindle is the rotating part of the machine that holds the cutting tool. The tool holder is used to secure the cutting tool in place. The bed is the base of the machine and provides support for the spindle and tool holder.

The CNC turning lathe is operated by a computer program that is programmed with the desired cutting parameters. The program is then loaded into the machine and the cutting process is initiated.

What does CNC stand for?

CNC stands for Computer Numerical Control. It is a type of automation technology used in the manufacturing industry to control machine tools such as lathes, mills, routers, and grinders. CNC machines are programmed with a set of instructions that tell the machine what to do and how to do it. The instructions are written in a computer language called G-code, which is a numerical code that tells the machine what to do. CNC machines are used to produce a wide variety of products, from simple parts to complex components. CNC machines are used in many industries, including aerospace, automotive, medical, and consumer products. CNC machines are highly accurate and can produce parts with very tight tolerances. CNC machines are also very efficient, allowing for faster production times and lower costs.

What is a CNC turning tool?

A CNC (Computer Numerical Control) turning tool is a type of cutting tool used in machining operations. It is a specialized tool that is used to shape and cut metal, plastic, and other materials. The tool is typically mounted on a CNC machine, which is a computer-controlled machine that is programmed to move the tool in a specific pattern to create a desired shape. The CNC turning tool is usually made of high-speed steel or carbide and is designed to rotate at high speeds. The tool is used to create a variety of shapes, including threads, grooves, and contours. It is also used to create complex shapes, such as those used in aerospace and automotive components. The CNC turning tool is typically used in conjunction with other cutting tools, such as drills, milling cutters, and reamers, to create the desired shape.

What is CNC milling and turning?

CNC (Computer Numerical Control) milling and turning are two of the most common machining processes used in the manufacturing industry. CNC milling is a subtractive manufacturing process that uses computer-controlled cutting tools to remove material from a workpiece in order to create a desired shape or geometry. CNC turning is a subtractive manufacturing process that uses computer-controlled cutting tools to remove material from a rotating workpiece in order to create a desired shape or geometry.

CNC milling is typically used to create complex shapes and features in a workpiece, such as slots, pockets, and contours. The cutting tool is typically a rotating end mill that is moved in three axes (X, Y, and Z) to create the desired shape. The cutting tool is usually held in a spindle that is driven by a motor. The workpiece is typically held in a vise or clamped to a table.

CNC turning is typically used to create cylindrical shapes and features in a workpiece, such as threads, grooves, and tapers.

What is the difference between CNC lathe and CNC turning?

CNC lathe and CNC turning are both types of computer numerical control (CNC) machining processes. CNC lathe is a type of CNC machining process that uses a rotating cutting tool to shape a workpiece. The cutting tool is typically a single-point cutting tool, such as a drill bit, that is moved along the workpiece in a linear direction. CNC turning is a type of CNC machining process that uses a rotating cutting tool to shape a workpiece. The cutting tool is typically a multi-point cutting tool, such as a milling cutter, that is moved along the workpiece in a circular direction.

The main difference between CNC lathe and CNC turning is the type of cutting tool used. CNC lathe uses a single-point cutting tool, while CNC turning uses a multi-point cutting tool. Additionally, CNC lathe is a linear process, while CNC turning is a circular process.

What is the difference between lathe and CNC?

The primary difference between a lathe and a CNC (Computer Numerical Control) machine is the way in which they are operated. A lathe is a manual machine tool that is used to shape a piece of material, such as metal or wood, by rotating it against a cutting tool. The cutting tool is held in a stationary position and the material is rotated against it. This allows the operator to shape the material into a desired shape. A CNC machine, on the other hand, is a computer-controlled machine tool that is used to shape a piece of material by moving the cutting tool along a predetermined path. The cutting tool is moved by a computer-controlled motor, and the material is moved along a predetermined path.

The main advantage of a CNC machine is that it is much more precise than a lathe. CNC machines are programmed to follow a specific path, and the cutting tool is moved along that path with great accuracy. This allows for much more precise cuts and shapes than can be achieved with a lathe.

How does a CNC lathe work?

A CNC (Computer Numerical Control) lathe is a type of machine tool that uses computer-controlled instructions to shape and cut materials. It is a type of automated lathe that is used to produce precision parts with a high degree of accuracy and repeatability. The CNC lathe is programmed with a set of instructions that tell the machine how to move and shape the material.

The CNC lathe consists of a spindle, a tool holder, a bed, and a control panel. The spindle is the rotating part of the machine that holds the cutting tool. The tool holder is the part of the machine that holds the cutting tool in place. The bed is the part of the machine that holds the material being cut. The control panel is the part of the machine that allows the operator to input instructions and control the machine.

The CNC lathe is programmed with a set of instructions that tell the machine how to move and shape the material. The instructions are written in a computer language called G-code.

What is a CNC lathe machinist?

A CNC (Computer Numerical Control) lathe machinist is a skilled worker who operates a CNC lathe machine to produce parts and components with a high degree of precision. CNC lathe machines are automated machines that use computer-controlled programs to shape and cut materials into desired shapes and sizes. The CNC lathe machinist is responsible for setting up the machine, loading the material, and programming the machine to produce the desired parts. The machinist must also monitor the machine during operation to ensure that it is running correctly and producing the desired results.

The CNC lathe machinist must have a thorough understanding of the machine and its capabilities, as well as the materials being used. They must also be able to read and interpret blueprints and technical drawings to ensure that the parts being produced meet the required specifications. The machinist must also be able to troubleshoot any problems that may arise during the operation of the machine.

Why is CNC turning important?

CNC (Computer Numerical Control) turning is an important machining process in the manufacturing industry because it allows for the production of complex parts with high precision and repeatability. CNC turning is a subtractive manufacturing process that uses a rotating cutting tool to remove material from a workpiece in order to create a desired shape. This process is advantageous because it is highly automated, allowing for the production of complex parts with a high degree of accuracy and repeatability. Additionally, CNC turning is a cost-effective process that can be used to produce parts in large quantities.

CNC turning is also a versatile process that can be used to produce a wide variety of parts. It can be used to produce parts with complex geometries, such as those with curved surfaces, tapers, and threads. Additionally, CNC turning can be used to produce parts with tight tolerances, which is important for ensuring that parts fit together properly and function as intended.

What is a 3 axis CNC lathe?

A 3 axis CNC lathe is a type of computer numerical control (CNC) machine tool that is used to shape and finish metal parts. It is a specialized type of lathe that is capable of performing multiple operations in a single setup, such as turning, drilling, boring, and threading. The 3 axes refer to the three directions in which the cutting tool can move: the X-axis, Y-axis, and Z-axis. The X-axis is the horizontal axis, the Y-axis is the vertical axis, and the Z-axis is the depth axis.

The 3 axis CNC lathe is a highly versatile machine tool that can be used to produce a wide variety of parts. It is capable of performing complex operations such as contouring, taper turning, and threading. It is also capable of producing parts with high accuracy and repeatability. The 3 axis CNC lathe is typically used in the production of parts for the automotive, aerospace, and medical industries.