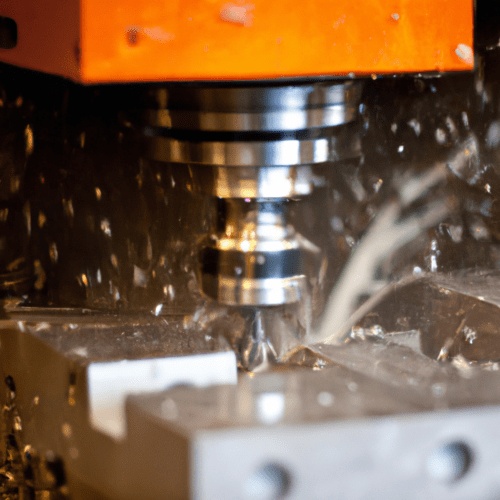

Computer numerical control (CNC) milling is a process used in the manufacturing industry that utilizes computerized controls and specialized cutting tools to produce parts and components from a variety of materials. The process involves the use of a rotating cutting tool, such as a drill bit, to remove material from the workpiece in precise and predetermined increments. CNC milling machines are programmed using specialized software and are capable of performing a variety of machining operations, including drilling, tapping, reaming, and milling. The software is used to specify the size, shape, and location of the cut, as well as the speed and depth of the cut. The machine then uses the programmed instructions to execute the operation. The CNC milling process is accurate and precise, and is often used to produce high-quality parts and components. The process is also relatively quick and cost-effective, making it a popular choice for many types of machining operations.

Introduction to CNC Milling Process and Its Benefits

CNC (Computer Numerical Control) milling is a machining process that uses computer-controlled cutting tools to create parts with a high level of precision and accuracy. This process allows for the production of complex shapes and designs with a high degree of repeatability. It is used in a variety of industries, from aerospace to automotive, and is becoming increasingly popular due to its numerous benefits. The CNC milling process begins with the creation of a numerical code which describes the desired shape and size of the part. This code is then used to control the CNC machine, which uses a cutting tool to shape the material. The machine can be programmed to cut at specific depths and angles, allowing for the production of intricate shapes and designs. It can also be programmed to create multiple parts with the same design in a single operation.

One of the greatest advantages of CNC milling is its accuracy and repeatability. CNC machines are able to produce parts with a high degree of precision, allowing for the production of complex designs with consistent results. In addition, the machines are able to repeat the same process multiple times, making it ideal for producing high volumes of parts with the same design. CNC milling is also highly cost-effective. The machines are able to produce parts quickly and efficiently, reducing the overall cost of production. Furthermore, the process requires minimal human intervention, which further reduces labor costs. Finally, CNC milling is incredibly versatile. The machines are able to work with a variety of materials, including metals, plastics, and composites. This makes them suitable for a wide range of applications, from medical device manufacturing to automotive production. CNC milling is an invaluable asset for any manufacturing operation. The process offers a variety of benefits, including accuracy, repeatability, cost-effectiveness, and versatility. It is an essential tool for the production of high-quality parts with complex designs.

Exploring the Different Types of CNC Milling Machines

CNC milling machines are a type of machining tool commonly used in industrial applications. They are computer-controlled machines that use a variety of cutting tools to shape a range of materials. CNC milling machines are used for a variety of purposes, from producing simple parts to creating intricate components and complex shapes. There are several different types of CNC milling machines available, each designed for specific applications. The most common types are vertical, horizontal, and universal. These machines can be used for a variety of applications, from fabricating parts for aerospace projects to creating components for medical devices. Vertical CNC milling machines are the most common type of CNC machine. They are designed for machining operations that require precision, accuracy, and repeatability. They are ideal for cutting metal, plastic, and wood materials. Vertical CNC machines are available in a variety of sizes and configurations, making them suitable for both large and small production runs.

Horizontal CNC milling machines are designed for machining operations that require a larger work area. They are ideal for producing large parts, such as engine blocks and molds. Horizontal CNC machines are also capable of producing complex shapes. Universal CNC milling machines are a combination of vertical and horizontal machines. They are designed for machining operations that require both precision and accuracy. Universal CNC machines are ideal for creating components for medical devices, aerospace projects, and electronic circuit boards. CNC milling machines are a valuable tool for creating a variety of components and parts. They are precise, repeatable, and reliable, making them an essential part of any industrial operation. There are several different types of CNC milling machines available, each designed for specific applications. Understanding the different types of CNC milling machines and their capabilities can help you choose the right machine for your needs.

The Advantages of Using CNC Milling Process for Complex Parts

CNC milling is an automated machining process used to create complex parts from a variety of materials, such as aluminum, steel, and plastics. It is one of the most widely used processes in the manufacturing industry and has numerous advantages when compared to traditional machining processes. CNC milling offers greater accuracy, repeatability, and control over complex parts, making it a popular choice for the production of complex components. One of the greatest advantages of using CNC milling is its accuracy. The accuracy of CNC milling is far superior to traditional machining processes, as it is able to create parts with tight tolerances and high levels of precision. This high level of precision means that complex parts can be manufactured with fewer defects and fewer machining errors, resulting in a higher quality finished product.

Additionally, CNC milling allows for a greater level of repeatability in the production process, allowing for multiple parts to be produced with the same exact specifications. Another advantage of CNC milling is its level of control. CNC milling machines are able to quickly and accurately process complex parts, allowing for more complex geometries and shapes to be created. This level of control also helps to reduce costs by avoiding rework and scrap, as the machine can accurately create parts with minimal waste. Finally, CNC milling processes are also able to produce intricate details in a shorter amount of time, reducing the overall cost of production. CNC milling machines can be programmed to create intricate features in a matter of minutes, allowing for more complex parts to be produced in a shorter amount of time. This means that more complex parts can be produced in less time, reducing overall production costs. Overall, CNC milling offers numerous advantages over traditional machining processes for the production of complex parts. Its accuracy, repeatability, and control make it an ideal choice for the production of intricate and precise parts, while its ability to quickly and accurately produce intricate features helps to reduce production costs. By using CNC milling processes, manufacturers can create complex parts with higher levels of accuracy, repeatability, and control in a shorter amount of time.

Understanding CNC Milling Machine Programming

CNC milling machine programming is a vital part of any CNC machining process. It is the source code that tells the CNC machine what to do and how to do it. Understanding this programming language is essential for anyone who wants to use CNC machines effectively. At its most basic level, CNC milling machine programming is written in a computer language called G-code. This code consists of a series of commands that tell the machine what to do and how to do it. Each command consists of a letter and a number that tell the machine what type of action to take. For example, the G01 command tells the machine to move in a straight line. One of the most important aspects of CNC milling machine programming is the ability to understand coordinate systems. Coordinate systems are used to define the position of the cutting tool relative to the workpiece. This information is essential for the machine to know how to move and in what direction. In addition to coordinate systems, CNC milling machine programming also involves understanding the types of tools that can be used. Different types of tools are used for different types of cuts and operations.

For example, a drill bit is used to make holes in the workpiece, while an end mill is used to make more intricate shapes. Understanding the types of tools available and how they are used is essential for any CNC machinist. Finally, CNC milling machine programming involves understanding how to create programs. Programs are written in a language called G-code and they are the instructions that tell the machine how to move and what operations to perform. Writing programs requires a good understanding of G-code commands and the ability to think logically. CNC milling machine programming is a complex subject, but with a good understanding of the basics and some practice, anyone can become proficient in this skill. With a combination of knowledge and experience, CNC machinists can achieve amazing results and create intricate designs with their machines.

Tips for Achieving Maximum Precision with CNC Milling Processes

1. Use the Correct Machine Setup: Achieving maximum precision from CNC milling processes depends largely on having the right machine setup. Carefully adjust the cutting tool, spindle, and feed rate to ensure that the machinery is properly aligned and able to produce accurate results.

2. Use High-Quality Tooling: High-quality cutting tools are essential for achieving maximum precision with CNC milling processes. Investing in high-quality cutting tools can reduce the risk of errors and ensure that the end product is precise and accurate.

3. Utilize CAD/CAM Software: Utilizing CAD/CAM software can help streamline the CNC milling process and ensure accuracy. The software can be used to create detailed 3D models that can be used to program and control the machine.

4. Use a High-Quality Workpiece: Using a high-quality workpiece is essential for achieving maximum precision with CNC milling processes. Investing in high-quality raw materials can help reduce the risk of errors and ensure that the end product is accurate and precise.

5. Use High-Precision Measurement Tools: Using high-precision measurement tools is an essential part of achieving maximum precision with CNC milling processes. Investing in quality measurement tools can help reduce the risk of errors and ensure that the end product is accurate and precise.

6. Regularly Check and Adjust the Machine: Regularly checking and adjusting the machine is essential for achieving maximum precision with CNC milling processes. Checking the machine for wear and tear and making necessary adjustments can help reduce the risk of errors and ensure that the end product is accurate and precise.