What are different types of milling operations?

Milling operations are a type of machining process that uses a rotating cutting tool to remove material from a workpiece. The cutting tool can be a single-point cutting tool, such as a drill bit, or a multi-point cutting tool, such as a milling cutter. There are several different types of milling operations, each of which produces a different result.

One type of milling operation is face milling, which is used to create flat surfaces on a workpiece. This is done by using a cutter with multiple cutting edges that is mounted on a spindle and fed into the workpiece. The cutter rotates and moves along the surface of the workpiece, removing material as it goes.

Another type of milling operation is end milling, which is used to create a flat surface on the end of a workpiece. This is done by using a cutter with multiple cutting edges that is mounted on a spindle and fed into the end of the workpiece. The cutter rotates and moves along the end of the workpiece, removing material as it goes.

A third type of milling operation is peripheral milling, which is used to create a flat surface on the side of a workpiece. This is done by using a cutter with multiple cutting edges that is mounted on a spindle and fed into the side of the workpiece. The cutter rotates and moves along the side of the workpiece, removing material as it goes.

A fourth type of milling operation is contour milling, which is used to create a curved surface on a workpiece. This is done by using a cutter with multiple cutting edges that is mounted on a spindle and fed into the workpiece. The cutter rotates and moves along the surface of the workpiece, following the contour of the surface and removing material as it goes.

Finally, a fifth type of milling operation is form milling, which is used to create a specific shape on a workpiece. This is done by using a cutter with multiple cutting edges that is mounted on a spindle and fed into the workpiece. The cutter rotates and moves along the surface of the workpiece

What are the operations of milling machine?

Milling machines are a type of machine tool used for shaping solid materials and metals. They are often automated and operated by CNC (computer numerical control) and are typically used to machine flat surfaces, grooves, slots, gear teeth, threads, and other complex 3D shapes. The operations that can be performed on a milling machine include face milling, shoulder milling, end milling, slotting, drilling, reaming, tapping, and boring.

Face milling is the process of cutting flat surfaces into the workpiece. This is done by using a rotating cutter that moves in a straight line across the surface of the workpiece. Shoulder milling is the process of cutting a shoulder or a groove into the workpiece. This is done by using a rotating cutter that moves in a helical path along the surface of the workpiece. End milling is the process of cutting an end or a corner into the workpiece. This is done by using a rotating cutter that moves in a straight line along the end of the workpiece.

What operations can be performed on a vertical milling machine?

A vertical milling machine is a type of machine tool that is used for milling operations, which involves the removal of material from a workpiece by rotating a cutter against it. The vertical milling machine can perform a variety of operations, including drilling, boring, reaming, tapping, countersinking, and counterboring. It can also be used to create slots, grooves, and contours in a workpiece. Additionally, it can be used to create angled surfaces, as well as to cut threads and keyways. The vertical milling machine can also be used to perform operations such as facing, profiling, and pocketing. It can also be used to create complex shapes and patterns, as well as to perform operations such as helical interpolation and circular interpolation. The vertical milling machine is also capable of performing operations such as drilling, tapping, and milling in multiple axes.

What are the operations of milling machine step by step procedures?

Milling machines are used to shape solid materials such as metal, wood, and plastic. They are typically used to create precise shapes and sizes for products such as car parts, medical equipment, and consumer electronics. The operations of a milling machine can be broken down into several steps.

The first step is to select the type of milling machine that is best suited for the job. This will depend on the size and shape of the material that needs to be machined, as well as the desired accuracy and finish. Once the machine is selected, the material is loaded into the machine and secured in place.

The next step is to select the appropriate cutting tool for the job. This will depend on the material being machined and the desired finish. The cutting tool is then mounted onto the spindle of the milling machine.

The third step is to set the cutting parameters. This includes the speed of the spindle, the feed rate, and the depth of cut. These parameters will determine the quality of the finished product.

What are different types of milling machines?

Milling machines are tools used in the metalworking industry for shaping and cutting metal and other materials. There are several different types of milling machines, each with its own set of features and capabilities.

The most common type of milling machine is the vertical milling machine. This type of milling machine has a vertical spindle that moves in a perpendicular direction to the workpiece. It is used to cut slots, grooves, and other features into the workpiece. It can also be used to drill holes and perform other operations.

Another type of milling machine is the horizontal milling machine. This type of machine has a horizontal spindle that moves in a parallel direction to the workpiece. It is used to cut slots, grooves, and other features into the workpiece. It can also be used to drill holes and perform other operations.

What are the types of milling cutter?

Milling cutters are cutting tools typically used in milling machines or machining centers to perform milling operations (and occasionally in other machine tools). They remove material by their movement within the machine (e.g., a ball nose mill) or directly from the cutter’s shape (e.g., a form tool such as a hobbing cutter).

There are several types of milling cutters, including:

End Mills: End mills are the most common type of milling cutter and are used for a variety of applications such as slotting, profiling, and plunging. They are typically made from high-speed steel or carbide and have a variety of shapes and sizes.

Router Bits: Router bits are used for cutting and shaping wood, plastic, and other materials. They are typically made from high-speed steel or carbide and come in a variety of shapes and sizes.

Face Mills: Face mills are used for cutting flat surfaces and are typically made from high-speed steel or carbide.

How do you classify the different types of milling cutters explain any six?

Milling cutters are cutting tools typically used in milling machines or machining centers to perform milling operations (and occasionally in other machine tools). They remove material by their movement within the machine (e.g., a ball nose mill) or directly from the cutter’s shape (e.g., a form tool such as a hobbing cutter).

There are several types of milling cutters, each of which is designed for a specific purpose. The most common types are end mills, face mills, shell mills, and slitting saws.

End Mills: End mills are the most common type of milling cutters. They have cutting edges on the end and sides of the cutting body. They are used for making slots, grooves, and other features in a workpiece. They can also be used for drilling, reaming, and countersinking.

Face Mills: Face mills are used for cutting flat surfaces. They have a large diameter and multiple cutting edges on the face of the cutter.

What is column and knee type milling?

Column and knee type milling is a form of milling machine that uses a vertical spindle and a horizontal table to cut and shape materials. The spindle is mounted on a vertical column, which is connected to the base of the machine. The table is mounted on a knee, which is connected to the column and can be adjusted up and down. The spindle is driven by a motor, which is connected to the column and can be adjusted to different speeds.

The column and knee type milling machine is one of the most versatile and widely used milling machines. It is capable of performing a variety of operations, including cutting, drilling, boring, and reaming. It is also capable of performing complex operations such as contouring, profiling, and helical milling. The column and knee type milling machine is used in a variety of industries, including automotive, aerospace, and medical.

The column and knee type milling machine is a versatile and reliable machine that can be used for a variety of operations.

What is milling in manufacturing process?

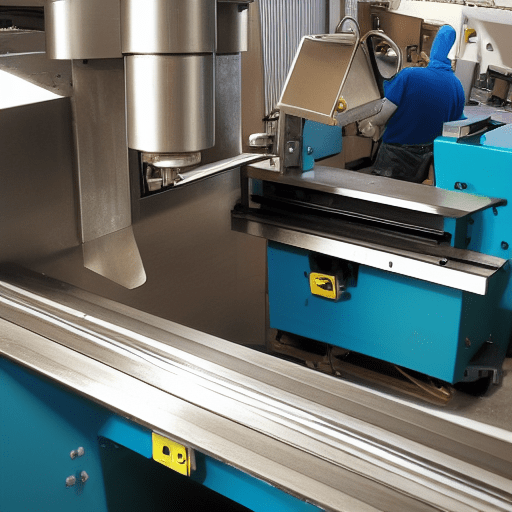

Milling is a manufacturing process that involves the use of a milling machine to shape and form materials such as metal, wood, or plastic. The milling machine uses a rotating cutting tool to cut away material from the workpiece in order to create the desired shape. The cutting tool is usually a multi-point cutting tool, such as an end mill, which is capable of cutting in multiple directions. The milling machine is also capable of performing other operations such as drilling, tapping, and reaming.

Milling is a versatile process that can be used to create a variety of shapes and features on a workpiece. It is commonly used to create flat surfaces, slots, grooves, and other features on the workpiece. It can also be used to create complex 3D shapes and contours. The milling process is often used in the production of parts for the automotive, aerospace, and medical industries.

Which type of machining can be done by milling machine?

Milling machines are a type of machine tool used for machining solid materials such as metal, wood, and plastic. They are capable of cutting and shaping a variety of materials, including metal, wood, plastic, and composites. Milling machines are used in a variety of industries, including automotive, aerospace, medical, and industrial manufacturing.

Milling machines are capable of performing a variety of operations, including cutting, drilling, boring, reaming, tapping, and threading. They can also be used to create complex shapes and contours. Milling machines are typically used to produce parts with precise dimensions and shapes. They are also used to create intricate patterns and designs.

Milling machines are capable of performing a variety of operations, including face milling, shoulder milling, end milling, slotting, and contouring. Face milling is used to create flat surfaces on a workpiece. Shoulder milling is used to create a shoulder on a workpiece. End milling is used to create a flat surface on the end of a workpiece.