When it comes to manufacturing precision parts, CNC machining is a go-to solution. With the advancements in technology, it has become easier than ever to create custom CNC machine parts that meet specific requirements. Whether you need cylindrical parts, machine components, or intricate car parts, CNC machining can deliver the precision and efficiency you need.

Two commonly used processes in CNC machining are CNC turning and CNC milling. CNC turning is ideal for creating cylindrical parts that are hollow on the inside, such as screws, nuts, and shafts. On the other hand, CNC milling is a versatile process that can produce precision drilling in a wide range of industries, including machine components, car parts, and electronics.

Key Takeaways

- CNC machining allows for the creation of versatile machine parts.

- CNC turning is used for cylindrical parts, while CNC milling provides precision drilling.

- Various industries, including automotive, aerospace, and electronics, benefit from CNC machining.

- Materials such as metals and plastics are commonly used in CNC machining.

- CNC machining offers advantages such as precision, efficiency, and customization.

Understanding CNC Turning and CNC Milling

In the world of CNC machining services, two common processes stand out: CNC turning and CNC milling. These processes play a vital role in the creation of precision parts for various industries. Let’s take a closer look at these two methods to understand how they work and their significance in CNC machining.

CNC Turning

CNC turning involves the rotation of the material at high speeds while the cutting tools remain stationary. This process allows for the creation of cylindrical parts with excellent precision. By removing material from a rotating workpiece, CNC turning is ideal for manufacturing components such as screws, nuts, bolts, and shafts. The resulting parts are often hollow on the inside, making them suitable for a wide range of applications.

CNC Milling

On the other hand, CNC milling keeps the material stationary while the cutting tools move to accomplish precise cuts and shapes. The milling machine utilizes rotating cutting tools that remove material from the workpiece. This process is highly versatile and can produce intricate designs and complex shapes with exceptional accuracy. CNC milling is widely employed in crafting machine components, car parts, electronics, and various industrial applications.

Both CNC turning and CNC milling are indispensable technologies in the realm of CNC machining services. The selection of the appropriate method depends on the desired outcome and the specific requirements of the project. By leveraging these processes, CNC machining service providers can deliver customized parts that meet the exact specifications and quality standards of their clients.

Parts You Can Create with CNC Turning

CNC turning is a highly versatile machining process that is particularly well-suited for creating cylindrical parts. This method allows for the production of parts that are hollow on the inside, making it ideal for a wide range of applications in various industries.

Some of the parts that can be created using CNC turning include:

- Screws

- Nuts

- Shafts

- Connectors

- Machine parts

CNC turning offers precise control over the dimensions and surface finish of the parts, ensuring the desired specifications are met. The process can accommodate different materials, allowing for the creation of parts that are durable, functional, and of high quality.

Whether you need intricate connectors for electronics, precisely threaded screws, or custom machine parts, CNC turning provides the capability to produce these cylindrical components with precision and efficiency.

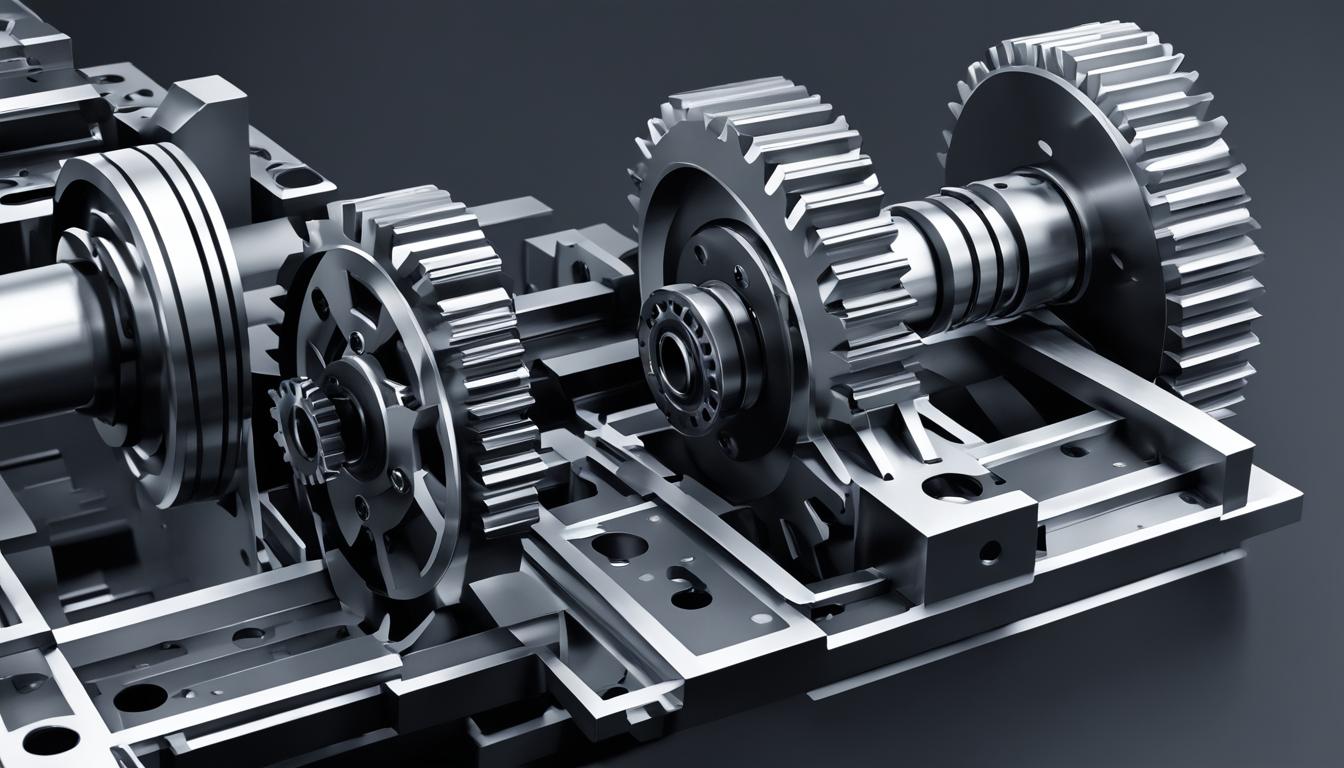

Take a look at the image below to see an example of a CNC turned part:

With the versatility of CNC turning, the possibilities for creating precise cylindrical parts are virtually endless. Let’s explore further in the next section how CNC milling can expand the range of parts that can be manufactured.

Parts You Can Create with CNC Milling

CNC milling is a versatile process that allows for precision drilling in various industries. With the capability to create complex shapes and intricate designs, CNC milling is used to produce a wide range of parts.

In the automotive industry, CNC milling is utilized to create car parts such as engine components, transmission parts, and chassis components. The precision drilling offered by CNC milling ensures the accurate production of these critical car components.

In the electronics industry, CNC milling is employed to manufacture precise and intricate parts for electronic devices. This includes components for printed circuit boards (PCBs) and electronic enclosures.

Furthermore, CNC milling is widely used in the production of machine components. From small machine parts to large industrial components, CNC milling ensures the precise drilling required for optimal functionality.

Other industries that benefit from CNC milling include the medical industry, where it is used to produce medical tools and instruments with precision and reliability. Additionally, CNC milling plays a vital role in the creation of jewelry, with intricate designs and high-quality finishes achievable through this process.

The military and defense sectors also rely on CNC milling for the production of various equipment and parts. CNC milling allows for the creation of military-grade components with precise drilling and dimensional accuracy.

Below is a representation of the diverse parts that can be created with CNC milling:

| Industry | Parts Created with CNC Milling |

|---|---|

| Automotive | Engine components, transmission parts, chassis components |

| Electronics | PCB components, electronic enclosures |

| Machine Components | Precision machine parts |

| Medical | Medical tools, surgical instruments |

| Jewelry | Intricate jewelry designs |

| Military | Military equipment, precision parts |

CNC Machining in Different Industries

CNC machining is widely used in various industries for its precision and efficiency. Let’s explore how CNC machining is utilized in different sectors:

1. Automotive Industry

In the automotive industry, CNC machining plays a vital role in producing high-quality engine components, transmission parts, and chassis components. With CNC machining, manufacturers can achieve the tight tolerances and intricate designs required for optimal performance.

2. Aerospace Industry

The aerospace industry relies heavily on CNC machining for the production of complex and critical parts. Turbine blades, landing gear parts, and other intricate components are manufactured using CNC machining due to its ability to achieve precision and maintain strict quality standards.

3. Electronics Industry

In the electronics industry, CNC machining is utilized for the fabrication of printed circuit boards (PCBs) and electronic enclosures. CNC machines are capable of creating intricate designs on PCBs, ensuring the precise placement of components and enabling the production of high-quality electronics.

4. Medical Industry

CNC machining plays a significant role in the medical industry, where precision is paramount. Surgical instruments, implants, and prosthetics are produced using CNC machining to achieve the required accuracy and ensure optimal performance and patient satisfaction.

5. Energy Industry

The energy industry relies on CNC machining for the production of various components. CNC machines are used to manufacture turbine components, pump and valve bodies, and drilling equipment parts. The precision and efficiency of CNC machining contribute to the reliability and performance of these critical energy components.

By leveraging the capabilities of CNC machining, industries can achieve exceptional precision, streamline production processes, and produce high-quality parts that meet industry standards and customer expectations.

| Industry | Applications |

|---|---|

| Automotive | Engine components, transmission parts, chassis components |

| Aerospace | Turbine blades, landing gear parts |

| Electronics | Printed circuit boards, electronic enclosures |

| Medical | Surgical instruments, implants, prosthetics |

| Energy | Turbine components, pump and valve bodies, drilling equipment parts |

Common Materials Used in CNC Machining

CNC machining is a versatile process that can work with a wide range of materials. The choice of material for CNC machining depends on various factors such as mechanical properties, environmental conditions, and tolerance requirements. Some commonly used materials in CNC machining include metals like aluminum, stainless steel, titanium, brass, and steel, as well as plastics like ABS, nylon, polycarbonate, polypropylene, and acrylic.

When it comes to CNC machining with metals, different metals offer unique properties and characteristics. For example, aluminum is lightweight, corrosion-resistant, and has excellent thermal conductivity, making it suitable for aerospace components and consumer electronics. Stainless steel is durable, resistant to corrosion, and commonly used in automotive parts and medical equipment. Titanium is known for its high strength-to-weight ratio and is often used in the aerospace industry. Brass offers good electrical conductivity and is often utilized in electrical components and plumbing fittings. Steel, on the other hand, is strong, versatile, and widely used in various industries.

For CNC machining with plastics, different types of plastics offer different properties and advantages. ABS is a versatile thermoplastic that is impact-resistant and widely used in the automotive industry and consumer products. Nylon is known for its durability, flexibility, and resistance to wear and tear, making it suitable for gears, bearings, and mechanical components. Polycarbonate is transparent, highly impact-resistant, and commonly used in industries such as aerospace, electronics, and medical. Polypropylene is lightweight, chemical-resistant, and often utilized in packaging, automotive parts, and appliances. Acrylic is a transparent material used in signage, displays, and protective barriers.

Overall, the choice of material in CNC machining is crucial in determining the final properties, performance, and functionality of the machined parts. By selecting the right material based on the specific requirements of the application, CNC machining can achieve precise and high-quality results.

Choosing the Right Material for CNC Machined Parts

When it comes to CNC machined parts, selecting the right material is crucial for ensuring functionality, durability, and cost-effectiveness. Several factors should be considered during the material selection process, including mechanical properties, material compatibility with the application, cost and availability, machinability, industry standards and certifications, tolerance requirements, heat resistance, and corrosion resistance.

The mechanical properties of the material play a vital role in determining its suitability for the intended application. Factors such as strength, hardness, elasticity, and wear resistance should be evaluated to ensure that the material can withstand the required load and environmental conditions.

Material compatibility is another important consideration. It is essential to choose a material that is chemically compatible with the application to prevent corrosion, degradation, or failure. For example, in industries where exposure to harsh chemicals is common, selecting a material with excellent chemical resistance is crucial.

Cost and availability are significant factors that can impact the feasibility of using a particular material. It is important to consider the cost-effectiveness of the material throughout the manufacturing process, including the procurement, machining, and finishing stages. Availability of the material should also be taken into account to ensure a consistent supply chain.

Machinability refers to the ease with which a material can be shaped, drilled, and finished during the CNC machining process. Choosing a material with good machinability can help optimize production time and reduce costs.

Industry standards and certifications are essential, especially in regulated industries. It is important to select materials that meet the required standards and certifications to ensure compliance with industry regulations and quality standards.

Specific tolerance requirements need to be considered when choosing a material. Some applications may require tight tolerances, while others may have more lenient tolerance requirements. Selecting a material that can achieve the desired tolerance is crucial for the success of the project.

Heat resistance is another consideration, particularly in applications where the parts will be exposed to high temperatures. Choosing a material with good heat resistance can help prevent deformation or failure under extreme heat conditions.

Corrosion resistance is essential in applications where the parts may come into contact with moisture, chemicals, or other corrosive substances. Selecting a material with excellent corrosion resistance properties can prolong the lifespan of the CNC machined parts.

Overall, the right material choice is crucial in CNC machining to ensure that the final product meets the required specifications and performs optimally in its intended application. Considering factors such as mechanical properties, material compatibility, cost and availability, machinability, standards and certifications, tolerance requirements, heat resistance, and corrosion resistance will help in selecting the most suitable material for CNC machined parts.

Additional Product Ideas for CNC Machining

Looking to explore more creative possibilities with CNC machining? In addition to the commonly made parts, this versatile process opens up a whole new realm of product ideas. From personal accessories to unique collectibles, the sky’s the limit. Here are some exciting product ideas that can be brought to life with CNC machining:

- Pet tags: Customizable tags for your furry friends, ensuring their safety and style.

- Unique knives: Exquisite and one-of-a-kind pieces for knife collectors and enthusiasts.

- Desk accessories: Elevate your workspace with CNC-machined pen holders and car models.

- Metal artwork: Intricate and visually stunning pieces of decorative metal artwork.

- Keyholders: Functional yet stylish keyholders to keep your keys organized.

- Phone stands: Hands-free convenience with sleek and innovative phone stands.

- Car badges: Custom-designed badges that add a touch of personalization to your vehicle.

- Machine spare parts: Precise replacement parts to keep your machines running smoothly.

- Custom engravings: Add a personal touch to various items with custom engravings.

- Stamps: Create unique designs for stamps, perfect for adding a personal touch to paper crafts or business branding.

- Toys: CNC-machined toys that are not only fun to play with but also beautifully crafted.

- Jewelry: Exquisite and intricate jewelry pieces with fine details and precision.

Whether you’re looking to express your creativity, showcase your brand, or add a touch of uniqueness to everyday items, CNC machining offers endless possibilities. Let your imagination soar and turn your product ideas into reality with the precision and quality that CNC machining provides.

Advantages of CNC Machining

CNC machining offers several advantages that make it a preferred choice in the manufacturing industry. Let’s explore these benefits:

Precision

CNC machining ensures precise and accurate results. With advanced computer-controlled systems, CNC machines can achieve consistent precision and high-quality output. This level of accuracy is essential for industries that require tight tolerances and intricate designs.

Efficiency

Compared to traditional machining methods, CNC machining is highly efficient. It eliminates the need for manual operation, reducing human errors and increasing productivity. CNC machines can work continuously, allowing for faster production and shorter lead times.

Flexibility in Customization

CNC machining offers remarkable flexibility when it comes to customization. It can produce complex designs and intricate details with ease, enabling the creation of unique and customized parts. Whether it’s prototyping or small-scale production, CNC machines can handle various designs and specifications.

High Accuracy

Accuracy is a crucial aspect of CNC machining. The computer-controlled precision of CNC machines ensures that each part is produced with consistent quality and dimensional accuracy. This reliability is vital in industries where precise and reliable components are required.

These advantages of CNC machining make it an invaluable tool in the modern manufacturing landscape. The precision, efficiency, customization capabilities, and high accuracy offered by CNC machining contribute to improved product quality and streamlined production processes.

| Advantages of CNC Machining |

|---|

| Precision |

| Efficiency |

| Flexibility in Customization |

| High Accuracy |

Affordable CNC Machines for Hobbyists and DIYers

CNC machines are no longer limited to industrial settings. Thanks to advancements in technology and user-friendly software, CNC machines have become more affordable and accessible to hobbyists and DIYers. This opens up a world of possibilities for individuals who want to bring their creative ideas to life.

With affordable CNC machines, hobbyists and DIYers can now explore the realms of precision manufacturing and turn their concepts into reality. These machines offer the same level of accuracy and precision as industrial-grade CNC machines but at a fraction of the cost.

Benefits of Affordable CNC Machines

1. Affordability: The cost of CNC machines has significantly reduced over the years, making them more accessible to individual users.

2. User-Friendly Software: CNC machines now come with intuitive and user-friendly software that simplifies the operation process. Even those with minimal experience can quickly learn how to operate the machines.

3. Precision: Affordable CNC machines offer excellent precision, allowing hobbyists and DIYers to create intricate designs and complex parts with ease.

4. Versatility: These machines can work with various materials including metals, plastics, and wood, giving users the flexibility to bring their ideas to life using a wide range of materials.

Examples of CNC Machine Projects for Hobbyists and DIYers

1. Customized Engravings: Use a CNC machine to create custom engravings on different materials such as wood, acrylic, or metal.

2. Desk Accessories: Design and manufacture unique desk accessories like pen holders, phone stands, or desktop organizers, personalized to suit your style and needs.

3. Metal Artwork: CNC machines can be used to create intricate metal artwork, such as wall decor, sculptures, or metal signs.

4. Keyholders and Car Badges: Design and produce personalized keyholders or car badges to add a unique touch to your belongings or vehicles.

5. DIY Toys: CNC machines allow you to design and fabricate your own toys, giving them a personal touch and making them memorable keepsakes.

With affordable CNC machines, hobbyists and DIYers can turn their ideas into reality without breaking the bank. Whether you want to create customized gifts, unique home décor, or even launch your own small-scale production, CNC machines provide the tools you need to bring your creative visions to life.

Conclusion

CNC machining is a versatile process that plays a crucial role in the manufacturing industry. With the use of CNC turning and CNC milling, a wide range of precision parts can be created to meet the demands of various industries. Whether it’s cylindrical parts for machinery, intricate components for cars, or essential elements for electronics, CNC machining delivers high-quality and reliable results.

The advantages of CNC machining are manifold. Its precision allows for the creation of complex designs with consistent accuracy. The efficiency of CNC machining ensures streamlined production processes, reducing both time and cost. Furthermore, CNC machining offers customization options, allowing for the creation of unique parts tailored to specific requirements.

The precision and efficiency of CNC machining make it an indispensable tool for manufacturers across industries. From aerospace and automotive to electronics and medical, CNC machining produces versatile parts that meet the highest standards. With CNC machining, manufacturers can achieve the desired precision, quality, and efficiency necessary for success in today’s competitive market.