Metal tube cutting offers numerous significant benefits for medical device manufacturing, enhancing precision, efficiency, and overall product quality. This advanced technique allows for the creation of intricate components with tight tolerances, crucial for devices such as catheters, endoscopes, and surgical instruments. By utilizing methods like laser cutting, electrical discharge machining (EDM), or CNC machining, manufacturers can achieve clean, burr-free cuts with minimal material waste. These processes also enable the production of complex geometries and micro-features that are essential for many medical applications.

Additionally, metal tube cutting techniques can improve the biocompatibility of devices by reducing surface contamination and maintaining material integrity. The ability to work with a wide range of metals, including stainless steel, titanium, and nitinol, further expands the possibilities for innovative medical device designs. Moreover, these cutting methods often result in reduced production times and costs, contributing to faster time-to-market for new medical technologies. The precision and consistency offered by metal tube cutting also enhance the reliability and performance of medical devices, ultimately leading to improved patient outcomes and safety in healthcare settings.

- Metal tubes offer precise dimensions and tight tolerances for medical device components.

- Advancements in materials enhance the performance of metal tubes in medical devices.

- Choosing the right material for specific applications is crucial.

- Cost factors should be considered when selecting metal tubing for medical device manufacturing.

- Metal tube cutting benefits include improved precision, efficiency, and cost-effectiveness.

Importance of Metal Tubing in the Medical Device Industry

Metal tubing plays a pivotal role in the medical device industry, serving as a foundational material for a wide range of applications. While plastic tubing has gained popularity in recent years, metal tubing remains an indispensable component in medical device machining and design.

The use of metal tubing in the medical device industry offers several unique advantages that make it a preferred choice for manufacturers. One of the key advantages is precision. Metal tubing allows for the production of components with the highest level of accuracy, ensuring a precise fit and performance in medical devices. The ability to achieve tight tolerances and small inside diameters enables the creation of intricate and complex designs.

Durability is another crucial attribute of metal tubing. Medical devices require materials that can withstand rigorous conditions and provide long-lasting performance. Metal tubing excels in these aspects, offering excellent resistance to wear, corrosion, and extreme temperatures. This durability ensures the reliability and longevity of medical devices in various healthcare applications.

Versatility is yet another notable advantage of metal tubing. It can be manufactured from a wide range of metals such as stainless steel, titanium, and nitinol, each with its own unique properties. This allows for customization based on the specific requirements of medical devices, enabling manufacturers to choose the most suitable material for their applications.

While the use of plastic tubing has increased in the medical device industry, metal tubing continues to be preferred due to its precision, durability, and versatility. Understanding the characteristics and applications of different materials is vital in making informed decisions and utilizing metal tubing effectively in medical devices.

| Advantages of Metal Tubing | Benefits for Medical Devices |

|---|---|

| Precision | Ensures accurate fit and performance |

| Durability | Withstands rigorous conditions for reliable performance |

| Versatility | Customizable based on specific requirements |

Benefits of Precision Cutting for Medical Devices

Precision cutting is a crucial aspect of medical device fabrication, offering numerous benefits to manufacturers. By utilizing precision cutting techniques in metal tube cutting, manufacturers can achieve accurate dimensions and tight tolerances, ensuring the quality and precision of each component.

Precision cutting is especially important in the production of intricate medical device parts such as catheters, stents, and implants. These components require precise measurements and designs to ensure proper functionality and performance.

By incorporating precision cutting methods, manufacturers can achieve consistent performance and improved quality control in the production process of medical devices. Precise cuts reduce errors and minimize the need for additional post-processing or modifications, streamlining the manufacturing workflow.

Overall, precision cutting in medical device fabrication enhances the accuracy, reliability, and quality of each component, contributing to improved performance and patient safety.

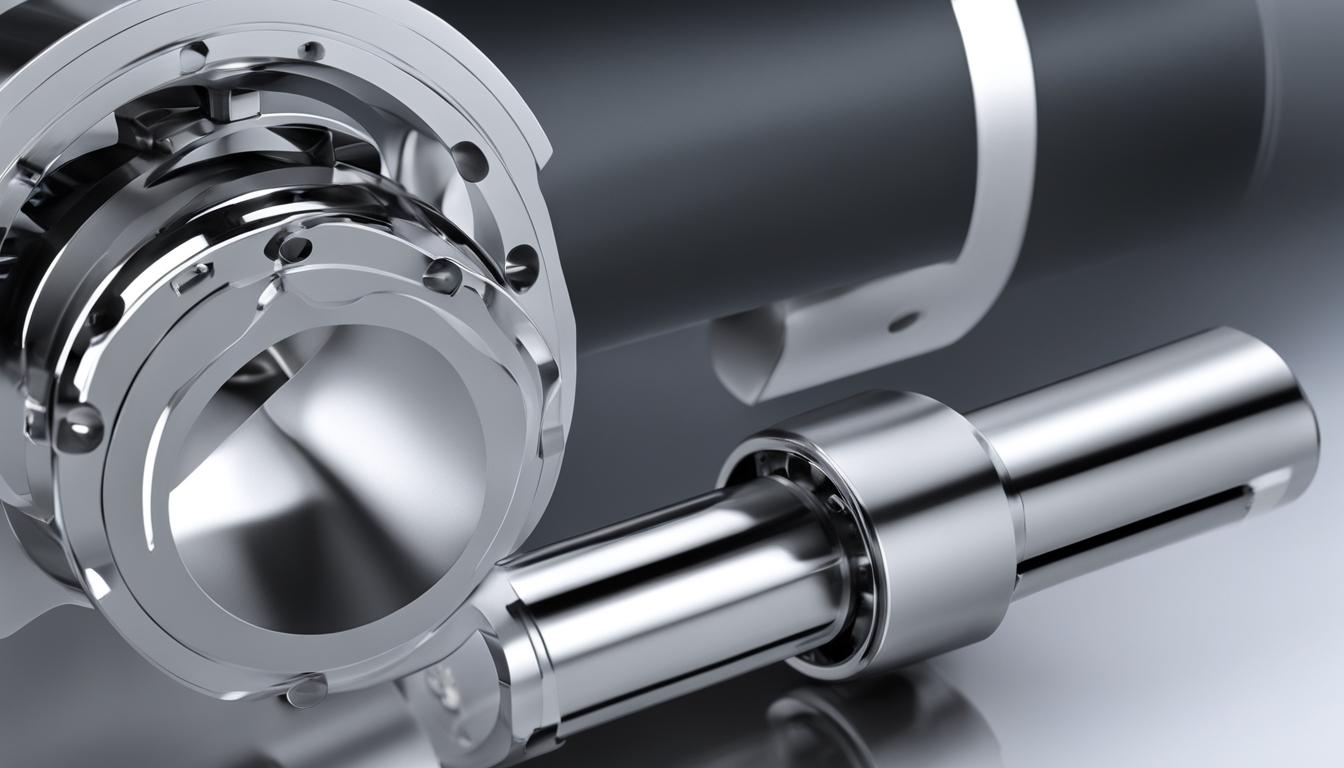

Figure: Precision cutting ensures accurate dimensions and tight tolerances in medical device fabrication.

Efficiency in Medical Tube Cutting

Efficiency plays a crucial role in the process of medical tube cutting, directly impacting the overall productivity and manufacturing of medical devices. With the advancement of cutting technologies, such as tube laser cutting machines, manufacturers can achieve enhanced efficiency, leading to increased productivity in medical device manufacturing.

Tube laser cutting machines offer high precision and speed, allowing manufacturers to produce a larger volume of parts in a shorter period. The use of automated systems and integrated work cells further enhances efficiency by reducing setup and cycle times, optimizing material usage, and streamlining the manufacturing workflow. These efficiency improvements contribute to increased productivity and reduced costs in the medical device industry.

One of the key benefits of enhanced efficiency in medical tube cutting is the ability to produce a higher quantity of accurately cut parts within a shorter timeframe. This not only increases the output of medical devices but also allows for faster fulfillment of market demands. In addition, reduced setup and cycle times result in optimized utilization of resources and improved overall manufacturing workflow.

Moreover, advanced cutting technologies enable manufacturers to achieve precise cuts with minimal material waste, leading to cost savings. By optimizing material usage, manufacturers can minimize material costs and reduce production waste, further enhancing the cost-effectiveness of medical tube cutting processes.

Overall, the enhanced efficiency in medical tube cutting brings several advantages to medical device manufacturing, such as increased productivity, reduced costs, and streamlined production processes. By leveraging advanced cutting technologies and optimizing workflow, manufacturers can meet the growing demands of the medical device industry while improving the overall production efficiency.

Clean and Accurate Metal Tube Cutting

In the medical device industry, clean and accurate metal tube cutting is crucial to ensure the production of high-quality and reliable medical tubes. Advanced cutting techniques, such as rolled tube technology, play a significant role in achieving precise cuts with complex features. This reduces the need for additional operations and costly processing, resulting in a streamlined production process for medical tubes.

One notable advancement in metal tube cutting is the integration of laser cutting equipment in CNC machines. This integration allows for precise cutting and machining in a single setup, eliminating the risk of misaligned features. The use of automated work cells and inspection systems further ensures the cleanliness and accuracy of each cut, minimizing errors and enhancing the overall quality of medical tubes.

By employing clean and accurate metal tube cutting methods, manufacturers can optimize their production processes and deliver medical tubes that meet the highest standards of quality. This not only improves the efficiency of the manufacturing process but also enhances the reliability and performance of medical devices.

Cost-Effectiveness in Cutting for Medical Devices

Cost-effectiveness is a crucial consideration in the manufacturing of medical devices. When it comes to metal tube cutting, there are several cost advantages to take into account. One cost-effective cutting technique is rolled tube technology, which can significantly reduce component and subassembly costs, particularly for single-use surgical devices. By optimizing material usage and minimizing waste through fully integrated systems and automated work cells, manufacturers can lower overall manufacturing costs.

Furthermore, considering various cost factors can further enhance cost-effectiveness in metal tube cutting for medical devices. The selection of materials plays a significant role in determining the overall cost of production. Manufacturers need to carefully evaluate the costs associated with different materials in terms of availability, durability, and compatibility with specific medical device applications. Additionally, choosing the right machining processes and volume requirements can help optimize production costs and ensure efficient manufacturing of medical devices.

Quality Control in Metal Tube Cutting

Quality control plays a vital role in the metal tube cutting process, ensuring that medical devices are reliable, functional, and safe. The use of advanced automation systems in metal tube cutting machines enables manufacturers to achieve a high degree of accuracy, precision, and uniformity in each cut. Automated processes provide improved quality control, reducing human errors and maintaining consistent performance throughout the production process.

In-line inspection using vision systems is an essential quality control measure in metal tube cutting. These systems enable manufacturers to inspect each component in real-time, ensuring that they meet the specified requirements. By incorporating automated quality control measures, manufacturers can identify any deviations or defects early on, preventing the production of faulty parts and ensuring the production of high-quality medical devices.

Automated processes in metal tube cutting machines not only improve quality control but also enhance overall part quality. The precision and accuracy achieved through automation result in consistent dimensions, tight tolerances, and smooth finishes for each component. This improved part quality translates to better performance, reliability, and longevity of the medical devices.

Additionally, the use of automation reduces the potential for human errors during the cutting process. Automated systems follow predefined parameters and cutting specifications, minimizing the risk of human mistakes. By eliminating human errors, manufacturers can maintain a high level of part quality and ensure that each component meets the required standards.

To summarize, quality control in metal tube cutting is critical for ensuring the reliability, functionality, and safety of medical devices. By leveraging advanced automation systems and implementing in-line inspection measures, manufacturers can achieve improved part quality, reduce human errors, and maintain consistent performance throughout the production process.

Increased Productivity in Medical Device Manufacturing

The use of tube laser cutting in medical device manufacturing has revolutionized the industry, leading to increased productivity and efficiency. Tube laser cutting machines offer numerous benefits that contribute to streamlining the production process and meeting the growing demand for medical devices.

One of the key advantages of tube laser cutting is its high speed and precision. These machines can cut through metal tubes with exceptional accuracy, ensuring consistent quality and reducing the need for manual adjustments. With faster cutting speeds, manufacturers can produce a larger volume of parts in less time, significantly increasing productivity.

Automated work cells and integrated systems further enhance productivity by minimizing setup time and combining multiple operations into one seamless process. By eliminating the need for manual intervention and reducing downtime between tasks, manufacturers can maximize efficiency and output without compromising quality.

The productivity benefits of tube laser cutting extend beyond the cutting process itself. These machines can integrate with other manufacturing systems and technologies, such as robotic arms and computer numerical control (CNC) systems, enabling a smooth and synchronized workflow. This integration eliminates unnecessary handling and transfers, minimizing the risk of errors and bottlenecks, and ultimately increasing productivity.

With increased productivity, medical device manufacturers can meet the growing demand for innovative devices, reduce lead times, and gain a competitive edge in the market. By leveraging the advantages of tube laser cutting, companies can streamline their manufacturing processes, optimize resource utilization, and deliver high-quality medical devices to healthcare providers and patients in a timely manner.

Advancements in Tube Laser Cutting Technology

Tube laser cutting technology in the medical field is continuously evolving, with several advancements and future trends on the horizon. These advancements are driving improvements in efficiency, accuracy, and productivity in the cutting process, ultimately benefiting medical device manufacturing.

Integration of Artificial Intelligence and Machine Learning Algorithms

One of the notable advancements in tube laser cutting technology involves the integration of artificial intelligence (AI) and machine learning algorithms. By leveraging AI capabilities, cutting parameters can be optimized based on real-time data analysis. This optimization enhances efficiency and accuracy, resulting in improved productivity and reduced material waste during the cutting process.

Advancements in Laser Technology

Advancements in laser technology have also contributed to the progress in tube laser cutting. Higher power lasers have been developed, increasing cutting speeds and capabilities. This allows for faster and more precise cutting of medical tubes, reducing production time and improving overall efficiency.

Automation and Robotics

The role of automation and robotics in tube laser cutting is expected to grow significantly in the future. Automated systems offer improved productivity and reduced human intervention, resulting in consistent and reliable cutting processes. The integration of robotics further enhances precision and flexibility, enabling complex cutting patterns and designs.

Embracing New Technologies

To stay ahead in the industry, it is crucial for medical device manufacturers to embrace these advancements and adopt new technologies. By keeping up with the latest developments in tube laser cutting, manufacturers can benefit from increased efficiency, improved quality, and reduced costs in the production of medical devices.

The future of tube laser cutting technology in the medical field holds immense potential for innovation and optimization. Continued research and development in this area will drive further advancements, leading to improved cutting techniques and enhanced manufacturing processes for medical devices.

Safety Considerations in Tube Laser Cutting for Medical Devices

Safety is of utmost importance when utilizing tube laser cutting machines in the medical field. Proper safety protocols and precautions should be followed to protect operators and create a safe working environment.

First and foremost, operators should always wear appropriate personal protective equipment (PPE) to safeguard against potential hazards. This may include safety glasses, gloves, and ear protection, depending on the specific requirements of the laser cutting machine being used.

Operators should also be highly aware of their surroundings and exercise caution when operating the machine. This includes keeping a safe distance from the laser beam, avoiding any potential obstructions, and ensuring proper ventilation in the workspace.

Additionally, it is crucial to follow the manufacturer’s instructions and guidelines for operating the tube laser cutting machine. Manufacturers design these machines with safety features in place, such as encased lasers and emergency stop buttons, to minimize risks and ensure safe operation.

Adhering to safety guidelines and maintaining a safety-conscious approach is crucial in preventing accidents and injuries during the tube laser cutting process. By prioritizing safety, operators can work confidently and efficiently, knowing that they are taking the necessary precautions to protect themselves and those around them.

| Common Safety Protocols for Tube Laser Cutting Machines |

|---|

| 1. Always wear appropriate personal protective equipment (PPE). |

| 2. Be aware of your surroundings and exercise caution. |

| 3. Follow the manufacturer’s instructions and guidelines. |

| 4. Keep a safe distance from the laser beam. |

| 5. Ensure proper ventilation in the workspace. |

| 6. Take regular breaks to prevent fatigue. |

| 7. Regularly inspect and maintain the machine. |

| 8. Train and educate all operators on machine safety. |

How to Choose a Tube Laser Cutting Machine for Medical Applications

When it comes to selecting a tube laser cutting machine for medical applications, there are several crucial factors to consider. First and foremost, it is essential to determine the types of materials that will be cut. Whether you’ll be working with ferrous or non-ferrous materials, choosing a machine specifically designed for those materials is paramount.

Another important consideration is the thickness of the material. You’ll want to ensure that the cutting speed of the machine aligns with the thickness of the tubes you’ll be working with. This will help you maintain optimal precision and efficiency throughout the cutting process.

Setting a budget is also a crucial step in the decision-making process. It’s essential to consider the price range of different tube laser cutting machine models and select one that meets your specific requirements without overspending. By taking the time to evaluate these factors thoroughly, healthcare professionals and manufacturers can choose the right tube laser cutting machine for their medical applications, maximizing its potential in the field.