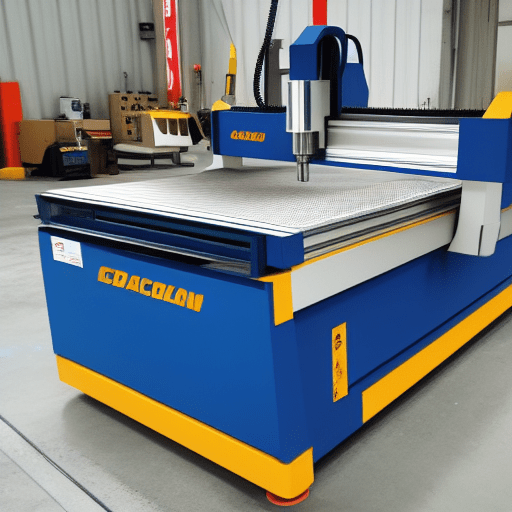

CNC routers are computer-controlled machines that are used to cut and shape materials such as wood, plastic, and metal. They are used in a variety of industries, including woodworking, metalworking, and plastics manufacturing. CNC routers are able to move in three dimensions, allowing them to create complex shapes and designs.

The way CNC routers move is through a combination of motors, gears, and linear motion systems. Motors are used to power the router, and gears are used to transfer the power from the motor to the router’s cutting head. Linear motion systems are used to control the router’s movement in the X, Y, and Z axes. The linear motion systems are typically driven by stepper motors, which are controlled by the CNC router’s computer.

The CNC router’s computer is programmed with instructions that tell the router how to move in the X, Y, and Z axes. The instructions are typically written in a language called G-code, which is a standard language used by CNC machines. The instructions tell the router how fast to move, how far to move, and what direction to move in. The instructions also tell the router how deep to cut into the material and how fast to cut.

Once the instructions are programmed into the CNC router’s computer, the router is able to move in the X, Y, and Z axes according to the instructions. The router is able to move quickly and accurately, allowing it to create complex shapes and designs with precision.

How does a CNC router work simple?

A CNC router is a computer-controlled cutting machine used to cut a variety of materials, such as wood, plastic, foam, and aluminum. It is a type of computer numerical control (CNC) machine, which is a computer-controlled cutting tool that uses a cutting tool to cut out shapes and designs from a material. The CNC router is programmed with a computer-aided design (CAD) program, which is used to create the design that will be cut out. The CNC router then uses a cutting tool, such as a router bit, to cut out the design.

The CNC router is programmed with a series of instructions that tell it how to move the cutting tool in order to cut out the design. The instructions are written in a language called G-code, which is a programming language specifically designed for CNC machines. The G-code instructions tell the CNC router how to move the cutting tool in order to cut out the design. The instructions also tell the CNC router how fast to move the cutting tool, how deep to cut, and how to adjust the cutting tool for different materials.

Once the CNC router is programmed with the G-code instructions, it is ready to begin cutting. The CNC router is connected to a computer, which is used to control the CNC router. The computer sends the G-code instructions to the CNC router, which then follows the instructions to cut out the design. The CNC router is also connected to a power source, which is used to power the cutting tool.

The CNC router is a powerful and precise tool that can be used to create a variety of shapes and designs. It is used in a variety of industries, such as woodworking, metalworking, and plastics manufacturing. It is also used in the production of signs, furniture, and other products.

Are CNC routers easy to use?

CNC routers are computer-controlled cutting machines used to create shapes and designs from a variety of materials. They are becoming increasingly popular for a variety of applications, from woodworking to metalworking. While CNC routers can be complex machines, they are relatively easy to use once you understand the basics.

The first step in using a CNC router is to create a design. This can be done using a variety of software programs, such as CAD or CAM. Once the design is complete, it is then loaded into the CNC router. The router then follows the instructions in the design to cut the material.

The CNC router is controlled by a computer, which allows for precise control of the cutting process. This makes it easier to create complex shapes and designs with a high degree of accuracy. The computer also allows for the use of a variety of cutting tools, such as end mills, drill bits, and saw blades.

In addition to the computer, CNC routers also require a few other components. These include a spindle, which is the motor that drives the cutting tool, and a controller, which is the device that sends instructions to the spindle. The controller is usually connected to the computer via a USB cable.

Once the design is loaded into the CNC router and the components are connected, the router is ready to begin cutting. The user can then adjust the speed and depth of the cut, as well as the type of tool being used. This allows for a high degree of control over the cutting process.

Overall, CNC routers are relatively easy to use once you understand the basics. With the right software and components, they can be used to create complex shapes and designs with a high degree of accuracy.

Which describes machine tool movement in CNC?

Computer Numerical Control (CNC) is a technology that uses computers to control the movement of machine tools. CNC machines are programmed with a set of instructions that tell the machine how to move in order to produce a desired result. The instructions are typically written in a computer language such as G-code, which is a language specifically designed for CNC machines. The instructions tell the machine how to move in three dimensions: X, Y, and Z. The X-axis is the horizontal movement, the Y-axis is the vertical movement, and the Z-axis is the depth of the cut. The instructions also tell the machine how fast to move, how deep to cut, and how much material to remove.

CNC machines are used in a variety of industries, including automotive, aerospace, and medical. They are used to create parts for cars, airplanes, and medical devices. CNC machines are also used to create molds and dies for injection molding and die casting. CNC machines are highly accurate and can produce parts with very tight tolerances.

CNC machines are typically controlled by a computer program that is written in a computer language such as G-code. The program is loaded into the machine and the machine is then able to execute the instructions. The instructions tell the machine how to move in three dimensions, how fast to move, how deep to cut, and how much material to remove. The instructions also tell the machine when to stop and when to start. CNC machines are highly accurate and can produce parts with very tight tolerances.

Can a CNC router cut through wood?

Yes, a CNC router can cut through wood. CNC routers are computer-controlled machines that are used to cut and shape a variety of materials, including wood. They are typically used in woodworking, furniture making, and other manufacturing applications. CNC routers are capable of cutting through wood with precision and accuracy, and can be used to create intricate designs and shapes.

CNC routers use a variety of cutting tools, such as end mills, drill bits, and router bits, to cut through wood. The cutting tools are mounted on a spindle, which is driven by a motor. The motor is controlled by a computer, which is programmed with the desired cutting parameters. The cutting tools are then moved along the wood in a precise pattern, cutting out the desired shape.

CNC routers are capable of cutting through a variety of woods, including hardwoods, softwoods, and plywood. The type of wood and the thickness of the material will determine the type of cutting tool that is used. For example, a router bit is typically used to cut through hardwoods, while an end mill is used to cut through softer woods.

CNC routers are also capable of cutting through a variety of other materials, such as plastics, aluminum, and steel. The type of material and the thickness of the material will determine the type of cutting tool that is used. For example, a router bit is typically used to cut through plastics, while an end mill is used to cut through aluminum and steel.

CNC routers are a great tool for woodworking and other manufacturing applications. They are capable of cutting through wood with precision and accuracy, and can be used to create intricate designs and shapes.

What way does a router spin?

A router is a tool used to shape and cut materials such as wood, plastic, and metal. It is typically used to create grooves, slots, and other shapes in the material. The way a router spins is determined by the type of router being used.

The most common type of router is the fixed-base router, which is designed to be mounted to a workbench or table. This type of router has a motor that is connected to a spindle, which is the part that spins. The motor is typically powered by electricity, and the speed of the spindle is controlled by a variable speed dial. The spindle spins in a clockwise direction, which is the same direction as the motor.

Another type of router is the plunge router, which is designed to be held in the user’s hands. This type of router has a motor that is connected to a spindle, which is the part that spins. The motor is typically powered by electricity, and the speed of the spindle is controlled by a variable speed dial. The spindle spins in a counterclockwise direction, which is the opposite direction of the motor.

The last type of router is the trim router, which is designed to be used for trimming and edging. This type of router has a motor that is connected to a spindle, which is the part that spins. The motor is typically powered by electricity, and the speed of the spindle is controlled by a variable speed dial. The spindle spins in a clockwise direction, which is the same direction as the motor.

In summary, the way a router spins is determined by the type of router being used. Fixed-base routers spin in a clockwise direction, plunge routers spin in a counterclockwise direction, and trim routers spin in a clockwise direction.

How many types of control systems in the CNC machine?

There are three main types of control systems used in CNC machines: open-loop, closed-loop, and hybrid. Open-loop control systems are the simplest type of CNC control system, and they rely on pre-programmed instructions to control the machine. This type of system does not use feedback from the machine to adjust the instructions, so it is not as precise as other types of control systems. Closed-loop control systems use feedback from the machine to adjust the instructions, making them more precise and accurate than open-loop systems. Finally, hybrid control systems combine elements of both open-loop and closed-loop systems to provide the most precise and accurate control of the machine. Each type of control system has its own advantages and disadvantages, so it is important to choose the right type of control system for the specific application.

How many types of CNC controllers are there?

There are several different types of CNC controllers available, each with its own unique features and capabilities. The most common types of CNC controllers are the open-loop controller, the closed-loop controller, the servo controller, the stepper controller, and the hybrid controller.

The open-loop controller is the simplest type of CNC controller, and it is used to control the motion of a machine by sending commands to the machine’s motors. This type of controller does not receive feedback from the machine, so it is not able to adjust its commands based on the machine’s performance.

The closed-loop controller is more complex than the open-loop controller, and it is used to control the motion of a machine by sending commands to the machine’s motors and receiving feedback from the machine. This type of controller is able to adjust its commands based on the machine’s performance, allowing for more precise control of the machine’s motion.

The servo controller is a type of closed-loop controller that is used to control the motion of a machine by sending commands to the machine’s servo motors. This type of controller is able to adjust its commands based on the machine’s performance, allowing for more precise control of the machine’s motion.

The stepper controller is a type of open-loop controller that is used to control the motion of a machine by sending commands to the machine’s stepper motors. This type of controller does not receive feedback from the machine, so it is not able to adjust its commands based on the machine’s performance.

The hybrid controller is a type of controller that combines the features of both the open-loop and closed-loop controllers. This type of controller is able to send commands to the machine’s motors and receive feedback from the machine, allowing for more precise control of the machine’s motion.

In summary, there are five main types of CNC controllers: the open-loop controller, the closed-loop controller, the servo controller, the stepper controller, and the hybrid controller. Each

Do CNC machines require any programming?

Yes, CNC machines do require programming. CNC stands for Computer Numerical Control, and the programming is what allows the machine to perform its automated functions. CNC programming is a language that is used to communicate instructions to the machine, telling it what to do and how to do it. The programming language is usually a combination of G-code and M-code, which are the two most common types of CNC programming. G-code is used to control the motion of the machine, while M-code is used to control the machine’s functions, such as spindle speed, coolant, and tool selection.

The programming language is usually written in a text editor, and then the program is loaded into the CNC machine’s memory. The program is then executed by the machine, which follows the instructions given in the program. The programming language is very precise and must be written correctly in order for the machine to perform its functions correctly.

CNC machines are used in a variety of industries, such as automotive, aerospace, and medical, and they are used to create a variety of products, from car parts to medical implants. CNC machines are highly precise and can produce complex shapes and parts with a high degree of accuracy. CNC programming is essential for the machine to be able to produce these complex shapes and parts. Without the programming, the machine would not be able to perform its automated functions.

What is CNC Tiktok?

CNC Tiktok is a Chinese-based social media platform that is similar to the popular app TikTok. It was created by the Chinese company ByteDance and is available in both Chinese and English. CNC Tiktok is a platform for users to create and share short videos, as well as interact with other users. It has a variety of features, including the ability to create and share videos, follow other users, comment on videos, and like and share videos. CNC Tiktok also has a variety of filters and effects that can be used to enhance videos. Additionally, users can create and join groups, as well as create and join challenges. CNC Tiktok also has a live streaming feature, which allows users to broadcast their videos to a larger audience. CNC Tiktok also has a variety of tools and features that can be used to help users create and share content, such as the ability to add music, text, and stickers to videos. CNC Tiktok also has a variety of safety features, such as the ability to block and report users, as well as the ability to set privacy settings.