Mechanical equipment is any machinery or device that uses force or motion to achieve a specific purpose. It can include components such as engines, motors, pumps, compressors, and other electromechanical or mechanical devices. Mechanical equipment is used in a wide variety of industries, including manufacturing, construction, mining, and energy production. Mechanical equipment is designed to be durable and reliable while providing efficient operation.

Exploring the Basics of Mechanical Equipment: Types, Uses, and Best Practices

Mechanical equipment is used in a variety of industries to perform a number of tasks. Mechanical equipment can range from simple tools like hammers to complex machines like bulldozers. Understanding the different types of mechanical equipment, their uses, and best practices for operating them is essential for ensuring the safety of workers and the successful completion of projects. Types of Mechanical Equipment Mechanical equipment can be divided into two broad categories: tools and machines. Tools are hand-held and typically used for smaller projects or tasks. Examples of tools include hammers, screwdrivers, wrenches, and saws. Machines are larger, more complex, and used for more extensive projects. Examples of machines include bulldozers, forklifts, cranes, and tractors. Uses of Mechanical Equipment Mechanical equipment is used in various industries for a variety of tasks. In construction, for example, tools and machines are used to build structures, while in agriculture machines are used to plow fields and transport crops. Other industries, such as manufacturing, rely on machines to produce products.

Best Practices for Using Mechanical Equipment Due to the size and power of mechanical equipment, it is important to use best practices when operating it. The following are some tips for safely operating mechanical equipment:

- Wear the appropriate safety gear, such as protective eyewear, gloves, and steel-toed boots.

- Read and understand the manual for the equipment before operating it.

- Make sure all safety features are working properly.

- Always keep a safe distance from other people or objects when operating the equipment.

- Stay alert and be aware of your surroundings.

- Follow all safety instructions and warnings from the manufacturer.

Conclusion Mechanical equipment is essential for a variety of tasks in various industries. Understanding the different types of mechanical equipment, their uses, and best practices for operating them is essential for ensuring the safety of workers and the successful completion of projects.

How to Properly Maintain and Inspect Mechanical Equipment

Maintaining and inspecting mechanical equipment is essential for ensuring the longevity and safety of the equipment. The following steps should be taken when maintaining and inspecting mechanical equipment:

1. Visual Inspection: A visual inspection should be completed on a regular basis to look for any damages or signs of wear and tear. This includes checking for cracks, dents, and corrosion. If any damage is noticed, further investigation should be done to determine the cause.

2. Cleaning: The equipment should be cleaned with a soft cloth and mild detergent to remove any dirt, dust, or other debris. This will help ensure the equipment is running efficiently and reduce the risk of any problems.

3. Lubrication: If applicable, lubricate all moving parts of the equipment to ensure they are running smoothly. This should be done with the recommended type of lubricant as specified by the manufacturer.

4. Testing: Depending on the type of equipment, it may be necessary to run tests to ensure it is functioning properly. This could include running the equipment under load or performing electrical tests.

5. Inspection of Parts: Carefully inspect all components of the equipment to make sure they are in good condition. Replace any worn or damaged parts as soon as possible. By regularly maintaining and inspecting mechanical equipment, you can help ensure it is running safely and efficiently. Doing so will help reduce the risk of any accidents or damages that could occur due to neglect.

The Latest Trends in Automation and Robotics for Mechanical Equipment

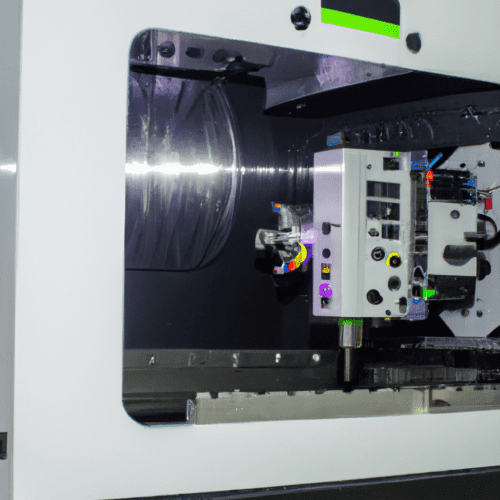

In recent years, the use of automation and robotics in mechanical equipment has grown exponentially. Automation and robotics are rapidly becoming an integral part of the manufacturing process, and they have the potential to revolutionize the way products are made. In order to stay competitive and keep up with the latest trends in automation and robotics, businesses must understand the different types of automation and robotics available and how they can be used to optimize their processes. One of the most popular automated systems is robotic assembly. This type of automation uses robotic arms to assemble parts and components into larger assemblies. This technology is often used in the automotive and aerospace industries, but it is also becoming increasingly popular in other industries such as electronics and medical device manufacturing. Another trend in automation and robotics is the use of computer numerical control (CNC) technology.

CNC technology is used to control and program robots and automated machinery. It allows for precise and accurate control of machine movements, and it can be used to program complex processes. CNC technology is becoming increasingly popular in the manufacturing sector, and many businesses are now using it to streamline and automate their processes. The use of 3D printing is another trend that is gaining popularity in the manufacturing sector. 3D printing is a process that uses special software and hardware to create 3D objects from a digital file. This technology can be used to produce prototypes and finished products quickly and economically. It has the potential to drastically reduce the cost of product development and production, making it an attractive option for businesses looking to reduce costs and maximize efficiency. Finally, the use of artificial intelligence (AI) is becoming increasingly common in the manufacturing sector. AI technology can be used to automate complex tasks and reduce the need for human labor. AI is being used to automate processes such as packaging, production scheduling, and inventory management.

As AI technology continues to improve, it is likely that more businesses will begin to utilize this technology to streamline their processes and reduce costs. Automation and robotics are rapidly becoming an integral part of the manufacturing process, and they have the potential to revolutionize the way products are made. In order to stay competitive and keep up with the latest trends in automation and robotics, businesses must understand the different types of automation and robotics available and how they can be used to optimize their processes. By understanding the potential of automation and robotics, businesses can ensure they are able to take advantage of the latest trends in order to maximize their efficiency and profitability.

What Are the Benefits of Investing in Mechanical Equipment?

Investing in mechanical equipment can provide a number of benefits for businesses. Mechanical equipment can increase production capacity and efficiency, as well as reduce labor costs and waste. By automating processes, businesses can improve quality control and reduce the risk of human error. In addition, mechanical equipment can reduce downtime and maintenance costs, while increasing energy efficiency and productivity. Investing in mechanical equipment can also help businesses keep up with the latest technology and stay competitive in the marketplace. Finally, mechanical equipment can improve safety in the workplace, minimize environmental impacts, and help businesses meet industry and regulatory standards.

How to Choose the Right Mechanical Equipment for Your Business Needs

When evaluating the right mechanical equipment for a business, there are several factors to consider. First and foremost, the purpose of the equipment should be identified. Is the equipment intended to increase production, improve safety or both? Knowing the intended purpose of the equipment will help determine the type of equipment that is necessary. Next, the size of the equipment must be taken into account. If the equipment is too large for the available space, it will not be able to function effectively. Additionally, it may be difficult to access or maintain. The size and weight of the equipment should be considered when evaluating the necessary space requirements. The cost of the equipment is also a factor when selecting the right mechanical equipment. Not only should the purchase price be taken into account, but also the maintenance costs. Some equipment may have a relatively low purchase price, but the cost of maintenance may be much higher.

Finally, the life expectancy of the equipment is an important factor to consider. Some equipment may have a relatively short life expectancy, while other equipment may have a much longer life expectancy. Investing in equipment with a longer life expectancy may save money in the long run, as it will not need to be replaced as often. By taking these factors into consideration, it will be easier to select the right mechanical equipment for a business’s needs. With careful research and planning, the right equipment can be identified that will provide the desired results and ensure the safety and well-being of the workers.