CNC machining, or CNC manufacturing, is a process using computer numerical control (CNC) in which pre-programmed computer software dictates the movement of factory tools and machinery. The cost of a CNC machine can vary widely depending on several factors, such as its size, complexity, and capabilities.

Are you looking to invest in a Laguna CNC machine? Understanding the pricing options is crucial for making an informed decision. In this guide, we will break down the cost of Laguna CNC machines and provide valuable insights to help you compare prices.

Key Takeaways

- CNC machines are widely used in various industries for precision manufacturing.

- Laguna CNC prices can range from affordable desktop machines to high-end commercial models.

- Factors such as size, complexity, and capabilities affect the cost of Laguna CNC machines.

- Comparing Laguna CNC prices will help you find the best option for your budget and requirements.

- Consider the specific needs of your project before deciding on a Laguna CNC machine.

What is CNC Machining/Milling?

CNC machining, or CNC manufacturing, is a process using computer numerical control (CNC) in which pre-programmed computer software dictates the movement of factory tools and machinery. It is a subtractive manufacturing process that employs code and machine tools to remove layers of material from a stock piece to produce a custom-designed part.

The cost of a Laguna CNC router will depend on the specific model and its capabilities.

Cost Comparison of Laguna CNC Routers

| Laguna CNC Router Model | Price | Key Features |

|---|---|---|

| Laguna Swift 4×8 | $19,995.00 | – Large cutting area – High precision – Industrial-grade components |

| Laguna IQ | $15,495.00 | – Compact size – User-friendly interface – Cutting-edge technology |

| Laguna SmartShop III | $79,175.00 | – Robust frame – Versatile capabilities – Advanced control system |

What is a CNC machine used for?

CNC milling machines are versatile tools that can be used for various applications in machining, shaping, and cutting materials. They are widely used in industries such as manufacturing, prototyping, woodworking, and metalworking. Here are some common uses of CNC milling machines:

- Machining and shaping parts: CNC milling machines are used to shape raw materials into precise and complex parts. Whether it’s creating intricate details or simple designs, these machines offer high precision and accuracy, ensuring consistent results.

- Prototyping: CNC milling machines are essential in the prototyping process as they allow designers to create physical models quickly. It enables them to test and refine their designs before mass production, saving time and resources.

- Production: CNC milling machines are used for large-scale production in industries such as automotive, aerospace, and furniture. They can efficiently produce multiple identical parts with minimal variations, ensuring high-quality and consistent output.

- Engraving and marking: CNC milling machines equipped with engraving tools can create intricate designs, logos, and text on various materials. This makes them valuable in industries such as signage, jewelry making, and customization.

- Woodworking: CNC milling machines are commonly used in woodworking to create intricate patterns, furniture components, and cabinetry. They offer precision and repeatability, allowing for efficient and accurate production.

- Metalworking: CNC milling machines can process various metals, including aluminum, steel, and brass. They can be used for cutting, drilling, and shaping metal parts with high precision and consistency.

The cost of a CNC milling machine can vary depending on its size, capabilities, and brand. Entry-level desktop CNC milling machines can start at around $2,000, while industrial-grade machines with advanced features can range from $20,000 to several hundred thousand dollars. It’s essential to consider your specific needs and budget when choosing a CNC milling machine.

How does a CNC Machine work?

CNC machines are automated machine tools that are controlled by a computer program. The machine moves the cutting tool along the path specified in the program, removing material from the workpiece to create the desired shape and dimensions. CNC stands for Computer Numerical Control, which refers to the use of computer software to control the machine’s movements.

At its core, a CNC machine consists of three main components: the computer, the controller, and the machine itself. The computer is used to design the part using CAD (Computer-Aided Design) software and convert it into a machine-readable format. The controller interprets the instructions from the computer and sends signals to the machine, telling it how to move and operate.

The process of CNC machining involves the following steps:

- Design: The part is designed using CAD software, which allows for precise specifications and measurements.

- CAM Programming: The CAD design is imported into CAM (Computer-Aided Manufacturing) software, which generates the toolpaths and instructions for the CNC machine.

- Setup: The workpiece is securely mounted onto the machine’s worktable, and the cutting tool is loaded into the machine.

- Execution: The CAM program is loaded into the machine’s controller, and the machine is started. The controller reads the program and sends signals to the machine’s motors to move the cutting tool along the specified paths.

- Cutting: The cutting tool removes material from the workpiece, following the instructions in the program. The machine may perform multiple passes or tool changes to achieve the desired result.

- Finishing: Once the cutting process is complete, the workpiece may undergo additional finishing operations, such as sanding, polishing, or painting, to achieve the desired surface quality.

The cost of an affordable CNC machine will depend on its size and capabilities. Affordable CNC machines are generally smaller and simpler in design, making them suitable for hobbyists, small businesses, or those on a budget. These machines typically have fewer advanced features but can still produce high-quality results.

Different Kinds of CNC Machines

There are various types of CNC machines available, each designed to perform specific tasks and cater to different industries. Let’s explore some of the most common types:

CNC Mills

CNC mills are versatile machines used for milling and cutting operations. They can create complex shapes and prototypes with high precision. Prices for CNC mills can range from affordable models for hobbyists to expensive industrial-grade machines.

Lathes

Lathes are used to shape cylindrical objects by rotating them against a cutting tool. CNC lathes offer automation and enhanced precision compared to manual lathes. The price of CNC lathes can vary depending on their size and specifications.

Plasma Cutters

Plasma cutters use ionized gas to cut through metal sheets. CNC-controlled plasma cutters provide accurate and efficient cutting capabilities. The cost of CNC plasma cutters depends on factors such as cutting area size and power capacity.

Electric Discharge Machines (EDMs)

EDMs use electrical discharge to shape and cut conductive materials. They are often used in precision manufacturing processes. CNC-controlled EDMs offer improved accuracy and repeatability. Prices for CNC EDMs can range from affordable models for small-scale operations to high-end machines for industrial use.

Water Jet Cutters

Water jet cutters utilize a high-pressure jet of water mixed with abrasive materials to cut through various materials such as metal, stone, and glass. CNC water jet cutters offer precise cutting capabilities and can handle a wide range of materials. The price range for CNC water jet cutters can vary depending on the size and power of the machine.

These are just a few examples of the different kinds of CNC machines available in the market today. The price range for CNC machines can vary greatly depending on the type of machine and its specific features and capabilities.

Maslow CNC Router Kit

The Maslow CNC Router Kit is a budget-friendly option for DIY enthusiasts and hobbyists. This kit offers an affordable solution for those looking to delve into CNC machining without breaking the bank. Compared to most 4×8 routers on the market, the Maslow CNC Router Kit comes at a significantly lower cost, making it an attractive choice for individuals with limited budgets.

Although the Maslow CNC Router Kit offers a cost-effective option, it’s important to note that it may not be suitable for professional use or intricate projects. The kit utilizes a chain system, which may result in limited precision when compared to more advanced CNC machines. Therefore, it’s best suited for hobbyists, small-scale projects, and those who prioritize affordability over intricate details.

Comparison of Maslow CNC Router Kit and Commercial-grade CNC Machines

| CNC Machine | Cost | Precision | Suitability |

|---|---|---|---|

| Maslow CNC Router Kit | Affordable | Limited* | Hobbyists, DIY Enthusiasts |

| Laguna Swift 4×8 CNC Router | Mid-range | High | Professionals, Businesses |

*Due to the chain system used in the Maslow CNC Router Kit, precision may be limited compared to commercial-grade CNC machines.

MakerMade M2

The MakerMade M2 is an improved version of the Maslow CNC Router Kit. It offers better rigidity and precision, making it a suitable choice for hobbyists and simple woodworking needs. The price of the MakerMade M2 falls within the affordable range for CNC machines.

If you’re looking for a reliable and cost-effective option, the MakerMade M2 is worth considering. With its enhanced features and affordable price range, it provides excellent value for woodworking enthusiasts and hobbyists. Whether you’re working on personal projects or need a reliable machine for DIY woodworking, the MakerMade M2 delivers consistent performance without breaking the bank.

Key Features of the MakerMade M2:

- Improved rigidity for enhanced precision

- Easy to assemble and operate

- Compatible with various materials for versatility

- Designed for hobbyists and woodworking enthusiasts

- Affordable price range

Experience the capabilities of the MakerMade M2 and take your woodworking projects to the next level. Its cost-effectiveness and improved performance make it a reliable choice for both beginners and experienced users.

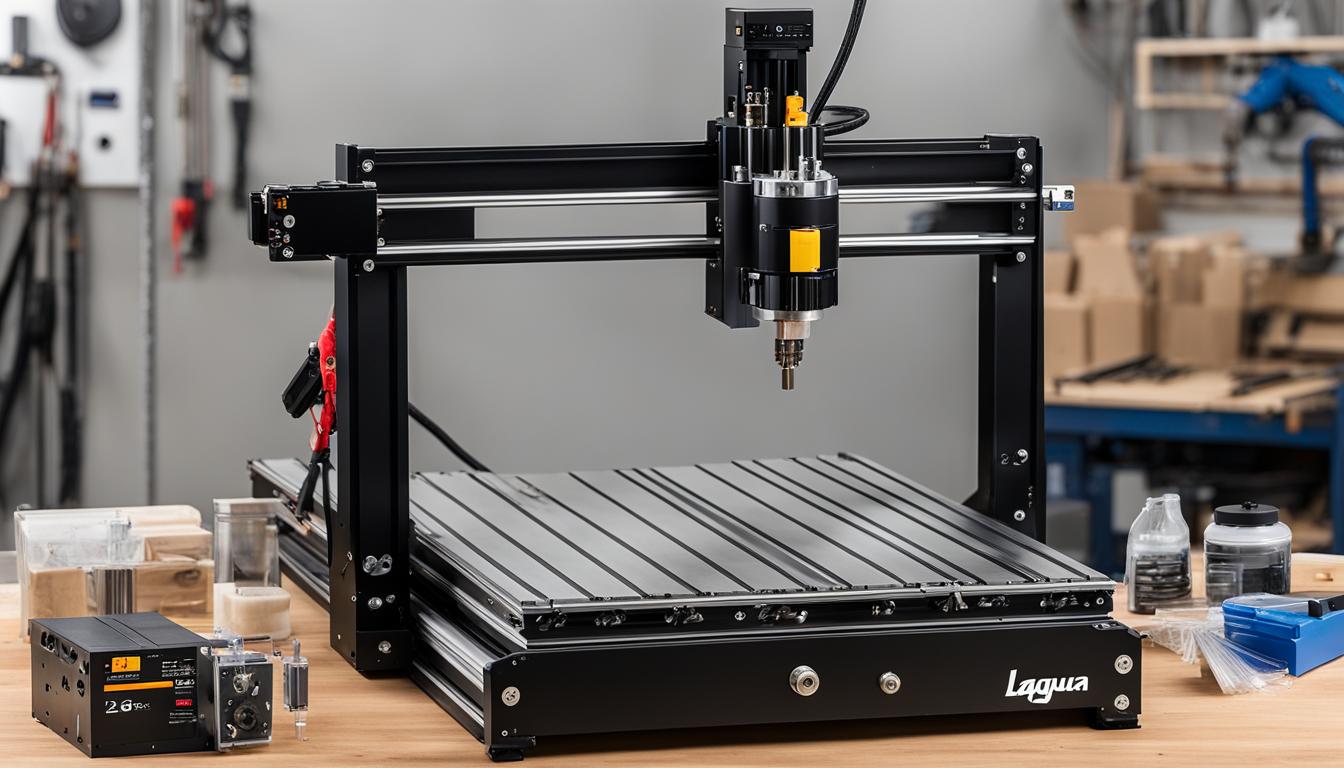

Laguna Swift 4×8 CNC Router

The Laguna Swift 4×8 CNC Router is a high-quality commercial-grade machine that offers exceptional performance and precision. With its advanced features and capabilities, this CNC router is specifically designed to meet the demands of businesses and professionals in various industries.

One of the standout features of the Laguna Swift 4×8 CNC Router is its expansive 4×8 cutting area, allowing for larger and more complex projects. This makes it an ideal choice for businesses that require increased production capacity and the ability to work with larger workpieces.

When it comes to pricing, the Laguna Swift 4×8 CNC Router falls within the mid-range category, making it a cost-effective option for businesses looking to invest in a reliable and high-performing CNC machine. The exact cost of the Laguna Swift 4×8 CNC Router will depend on the specific model and its additional features.