CNC (Computer Numerical Control) milling is a process used in the manufacturing industry that employs computerized controls to operate and manipulate machine tools like lathes, mills, and grinders. CNC milling has several advantages over traditional manual milling, including increased precision, improved accuracy, increased productivity, and improved safety.

One of the primary advantages of CNC milling is increased precision. CNC machines are able to produce parts with tighter tolerances than manual machines, which can result in improved product quality and reduced scrap. CNC machines are also able to produce parts with a higher degree of accuracy than manual machines, which can result in improved product performance.

CNC milling also offers increased productivity. CNC machines are able to produce parts faster than manual machines, which can result in reduced lead times and improved customer satisfaction. CNC machines are also able to produce parts with a higher degree of complexity than manual machines, which can result in improved product design.

CNC milling also offers improved safety. CNC machines are able to operate without the need for manual intervention, which can reduce the risk of operator injury. CNC machines are also able to operate with a higher degree of accuracy than manual machines, which can reduce the risk of product defects.

One of the primary disadvantages of CNC milling is the cost. CNC machines are more expensive than manual machines, which can result in increased capital costs. CNC machines also require more maintenance than manual machines, which can result in increased operational costs.

CNC milling also requires a higher level of skill than manual milling. CNC machines require a higher level of programming knowledge than manual machines, which can result in increased training costs. CNC machines also require a higher level of operator skill than manual machines, which can result in increased labor costs.

What are the advantages and disadvantages of CNC?

The advantages of CNC (Computer Numerical Control) machines are numerous. CNC machines are highly accurate, repeatable, and can produce complex parts with a high degree of precision. They are also able to produce parts quickly and with minimal waste, making them cost-effective and efficient. CNC machines are also relatively easy to program and operate, and can be used to produce a wide variety of parts.

The disadvantages of CNC machines are also worth considering. CNC machines require a significant initial investment, and can be expensive to maintain and repair. They also require a certain level of expertise to program and operate, and can be difficult to troubleshoot if something goes wrong. Additionally, CNC machines are limited in their ability to produce parts with complex geometries, and can be difficult to modify or adjust if the design of the part changes.

Why is CNC important?

Computer Numerical Control (CNC) is an important technology in modern manufacturing. It is a process in which a computer is used to control the movement of tools and machinery in order to create parts and products with a high degree of accuracy and repeatability. CNC is used in a wide variety of industries, from aerospace and automotive to medical and consumer products.

CNC is important because it allows for the automation of complex manufacturing processes. By using a computer to control the movement of tools and machinery, CNC can produce parts and products with a high degree of accuracy and repeatability. This eliminates the need for manual labor and reduces the amount of time and money required to produce a product. Additionally, CNC can be used to produce parts and products with complex shapes and features that would be difficult or impossible to produce with traditional manufacturing methods.

What are the disadvantages of CNC?

CNC (Computer Numerical Control) is a type of automation technology used in the manufacturing industry to control machine tools such as lathes, mills, routers, and grinders. CNC machines are highly accurate and can produce complex parts with a high degree of precision. However, there are some disadvantages associated with CNC machines.

One of the main disadvantages of CNC machines is their high cost. CNC machines are more expensive than traditional machine tools, and the cost of the software and training required to operate them can add to the overall cost. Additionally, CNC machines require regular maintenance and repairs, which can be costly.

Another disadvantage of CNC machines is that they require a high level of skill to operate. CNC machines are programmed using a computer language, and operators must be familiar with the language in order to program the machine correctly. Additionally, CNC machines require a high level of precision, and operators must be able to make adjustments to the machine in order to achieve the desired results.

What is the biggest disadvantage of using CNC?

The biggest disadvantage of using CNC (Computer Numerical Control) is the cost. CNC machines are expensive to purchase and maintain, and require a significant amount of training to operate. Additionally, CNC machines require a large amount of energy to run, which can be costly. Furthermore, CNC machines are not as flexible as manual machines, as they are limited to the specific programming that is used to control them. This means that if a part needs to be changed or modified, the entire program must be re-written, which can be time consuming and costly. Finally, CNC machines are not as accurate as manual machines, as they are limited by the precision of the programming. This can lead to errors in the finished product, which can be costly to fix.

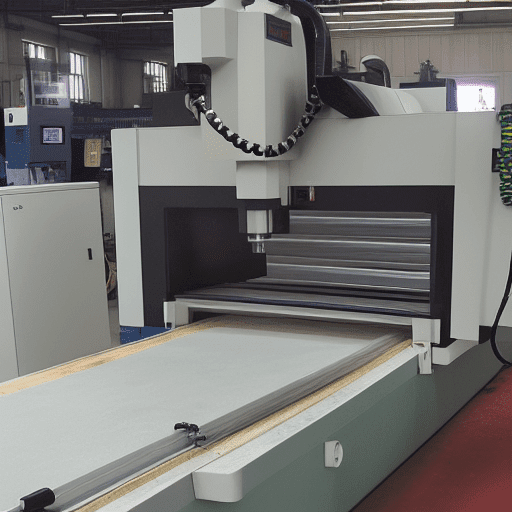

What is a CNC milling machine?

A CNC (Computer Numerical Control) milling machine is a type of machining tool that uses computer-controlled commands to cut and shape materials. It is a versatile tool that can be used to create a variety of shapes and components, from simple to complex. CNC milling machines are typically used in the manufacturing industry to create precision parts and components.

CNC milling machines are equipped with a variety of tools, such as drills, end mills, and routers, which are used to cut and shape the material. The machine is programmed with a set of instructions that tell it how to move the tool and what type of material to cut. The instructions are typically written in a computer language such as G-code. The machine then follows the instructions to cut the material to the desired shape and size.

CNC milling machines are highly accurate and can produce complex shapes with a high degree of precision. They are also capable of producing parts with a high degree of repeatability, meaning that the same part can be produced multiple times with the same results.

What is CNC?

CNC stands for Computer Numerical Control, and it is a type of automation technology used in the manufacturing industry. It is a process in which a computer is used to control the movement of a machine tool, such as a lathe, milling machine, router, or grinder. The computer is programmed with a set of instructions that tell the machine tool how to move and what operations to perform. CNC machines are used to produce a wide variety of products, from simple parts to complex components.

CNC machines are highly accurate and can produce parts with very tight tolerances. They are also very efficient, as they can produce parts quickly and with minimal waste. CNC machines are also very versatile, as they can be programmed to perform a variety of operations, such as drilling, milling, turning, and grinding.

What’s the advantages and disadvantages?

The advantages and disadvantages of something depend on the context in which it is being discussed. Generally speaking, advantages refer to positive outcomes or benefits, while disadvantages refer to negative outcomes or drawbacks.

Advantages can include increased efficiency, cost savings, better quality, improved customer service, increased safety, and more. Disadvantages can include increased costs, decreased efficiency, decreased quality, increased risk, and more.

For example, if a company is considering implementing a new technology, the advantages could include increased efficiency, cost savings, better quality, improved customer service, increased safety, and more. The disadvantages could include increased costs, decreased efficiency, decreased quality, increased risk, and more.

In addition, advantages and disadvantages can also be subjective. For example, a new technology may be seen as an advantage by some people, while others may view it as a disadvantage. It is important to consider all perspectives when evaluating the advantages and disadvantages of something.

Which of the following is a disadvantage of machining processes such as CNC milling or turning?

One of the main disadvantages of machining processes such as CNC milling or turning is the cost associated with them. Machining processes require specialized equipment and highly trained personnel, which can be expensive to acquire and maintain. Additionally, machining processes are often time-consuming, as they require precise measurements and calculations to be made in order to produce the desired result. This can lead to longer lead times for production, which can be a disadvantage for businesses that need to produce parts quickly.

Another disadvantage of machining processes is the potential for errors. Machining processes require a high level of precision, and any errors in the measurements or calculations can lead to parts that are not up to the desired specifications. This can lead to costly rework or scrap, which can be a significant financial burden for businesses.

Finally, machining processes can be limited in terms of the materials that can be used. Certain materials may not be suitable for machining processes, or may require special tools or techniques in order to be machined.

What are the advantages of using the CNC lathe?

The CNC lathe is a computer-controlled machine tool that is used to shape metal and other materials into a variety of shapes and sizes. It is a highly precise and automated machine that can produce complex parts with a high degree of accuracy and repeatability. The advantages of using a CNC lathe include:

1. Increased Productivity: CNC lathes are able to produce parts quickly and accurately, which increases productivity and reduces costs. The machine can be programmed to produce multiple parts in a single setup, which eliminates the need for multiple setups and reduces the amount of time needed to produce a part.

2. Increased Accuracy: CNC lathes are able to produce parts with a high degree of accuracy and repeatability. This is due to the fact that the machine is programmed with precise instructions and is able to follow them precisely. This eliminates the need for manual adjustments and ensures that the parts produced are of the highest quality.