CNC technology is a manufacturing process that uses computerized controls to operate and manipulate machine and cutting tools to produce precision parts and components. This advanced manufacturing method employs pre-programmed software to dictate the movement of factory machinery and tools, allowing for highly accurate and repeatable production of complex three-dimensional shapes. CNC technology is widely used across various industries, including aerospace, automotive, electronics, and medical devices. It enables manufacturers to create intricate parts with tight tolerances, reduce human error, increase production efficiency, and minimize material waste.

Common CNC machines include mills, lathes, routers, and plasma cutters, each designed for specific manufacturing tasks. The technology has revolutionized modern manufacturing by offering enhanced precision, consistency, and automation capabilities, making it an essential tool for producing everything from small electronic components to large aircraft parts. As CNC technology continues to evolve, it is increasingly integrated with other advanced manufacturing techniques, such as 3D printing and robotics, further expanding its applications and potential in the industrial sector.

- CNC technology uses preprogrammed computer software to automate machine tools.

- G-code language controls the movement and functioning of CNC machines.

- CNC technology offers benefits like cost reduction, waste reduction, and improved worker safety.

- CNC machines are used in industries such as aerospace, medical, automotive, electronics, oil and gas, and marine.

- CNC technology enables contour machining capabilities for precise part production.

How Does CNC Technology Work?

CNC technology, short for computer numerical control, operates through a sophisticated and automated process. Understanding how CNC technology works is essential in comprehending its role in modern manufacturing.

The process begins with engineers creating a detailed CAD drawing of the desired part to be manufactured. The CAD drawing serves as a digital representation of the physical object.

Once the CAD drawing is created, it is translated into G-code, a programming language understood by CNC machines. The G-code contains specific instructions that dictate the machine’s movements, tool paths, speeds, and other parameters.

After the G-code is generated, it is loaded onto the CNC machine. Before the actual production run, a test run is performed to verify the accuracy of the program and ensure that there are no errors or collisions.

During the manufacturing process, the CNC machine follows the G-code program precisely. It controls the movement of various machine tools, such as drills, lathes, or milling cutters, to shape and form the raw material according to the CAD design.

CNC systems can operate in either open-loop or closed-loop systems. In open-loop systems, the machine follows the programmed instructions without any feedback or error correction capabilities. In contrast, closed-loop systems use sensors and feedback mechanisms to monitor the machine’s performance and make real-time adjustments if necessary.

The use of CNC technology in manufacturing offers several advantages. It automates the manufacturing process, eliminating the need for manual intervention and reducing the likelihood of errors. CNC machines can achieve high levels of precision and repeatability, resulting in consistent and accurate parts.

Additionally, CNC technology allows for contour machining, enabling the creation of complex shapes and geometries that would be challenging or impossible with traditional methods.

| Advantages of CNC Technology | Description |

|---|---|

| Automation of Manufacturing Processes | CNC technology automates the manufacturing process, reducing the need for manual intervention and allowing for continuous operation without fatigue. |

| Precision and Accuracy | CNC machines offer high precision and accuracy in manufacturing, ensuring consistent quality and adherence to exact specifications. |

| Contour Machining Capabilities | They are capable of complex contour machining, allowing for the creation of intricate and detailed designs that would be difficult or impossible to achieve manually. |

| Reduced Human Error | By automating processes, CNC technology significantly reduces the chances of human error, leading to fewer mistakes and waste. |

| Increased Efficiency and Productivity | CNC machines can operate at a faster rate than manual processes, increasing overall efficiency and productivity in manufacturing. |

| Improved Safety for Workers | CNC machines minimize the need for direct human interaction with dangerous tools and machinery, enhancing safety in the manufacturing environment. |

The integration of CNC technology with CAD and CAM software further enhances its capabilities. This integration streamlines the design-to-production process, allowing engineers to create complex designs and convert them into machine-readable programs efficiently.

CNC technology revolutionizes modern manufacturing with its ability to automate processes, achieve precise results, and optimize efficiency. By embracing CNC technology, industries can embrace advanced techniques and stay competitive in a rapidly evolving global market.

Types of CNC Operations

CNC technology offers a versatile range of operations that cater to specific manufacturing needs. Each operation utilizes advanced computer-controlled machinery to achieve precise results. Let’s explore some of the most common types:

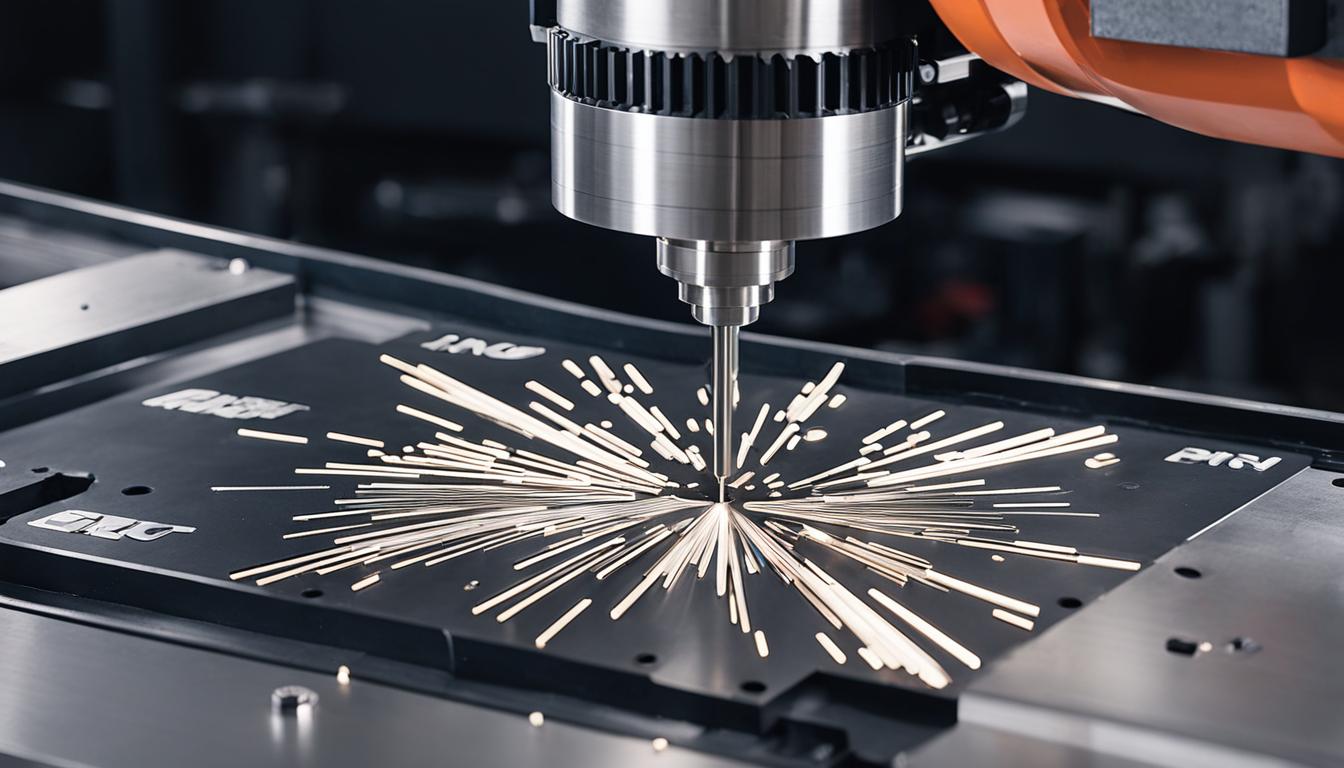

CNC Milling

CNC milling involves the use of rotating cutting tools to remove material and create complex shapes. It is widely used in industries such as automotive, aerospace, and prototyping.

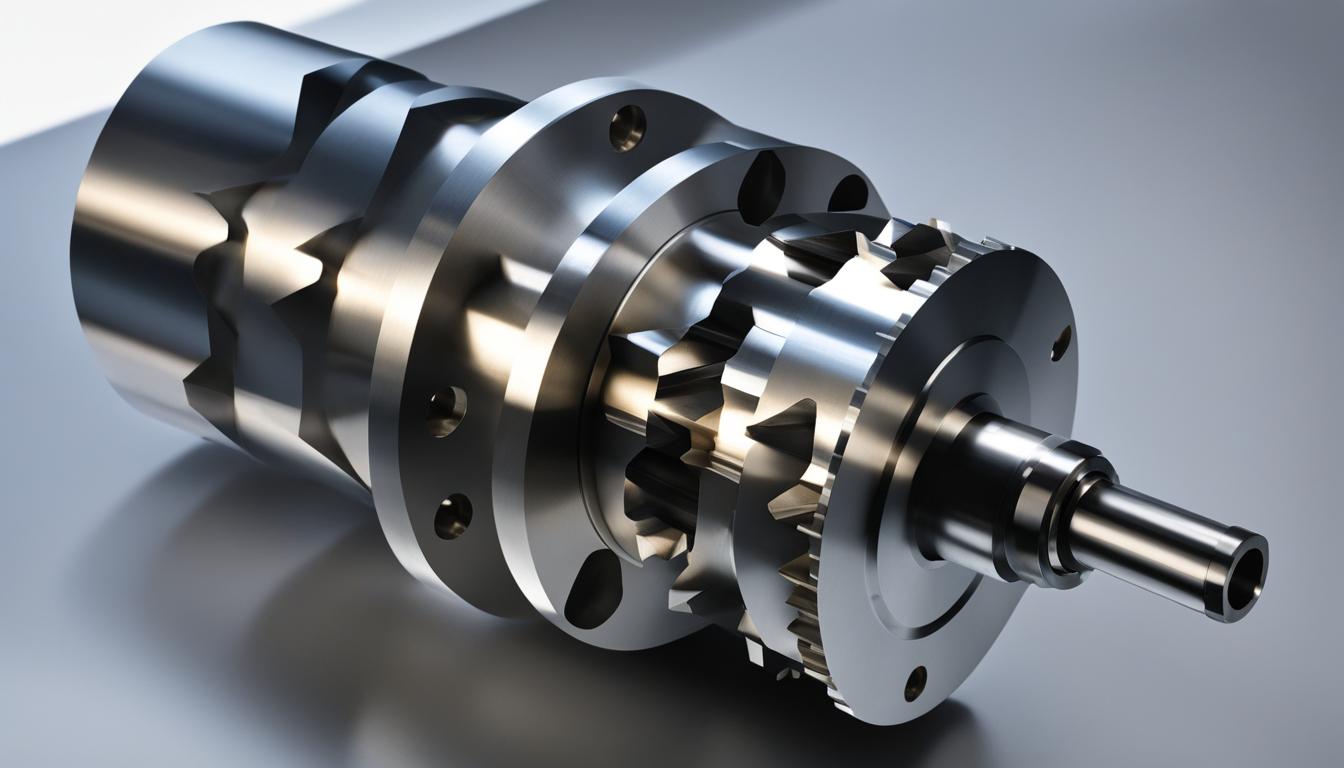

CNC Turning

CNC turning is employed when a workpiece rotates while a cutting tool shapes it. This operation is commonly used in the production of cylindrical shapes like shafts, valves, and fittings.

CNC Drilling

CNC drilling machines are designed to create precise holes in various materials. This operation ensures accuracy and consistency in hole placement, making it vital for industries such as construction and manufacturing.

CNC Laser Cutting and Plasma Cutting

CNC laser cutting and plasma cutting utilize high-energy lasers or plasma jets to accurately cut through materials. These operations are suitable for industries that require intricate and precise cuts, such as automotive, architecture, and signage.

CNC Waterjet Cutting

CNC waterjet cutting employs high-pressure water combined with abrasive materials to cut through different types of materials. This operation is particularly useful for industries that work with fragile or heat-sensitive materials.

CNC Routing

CNC routing is used to hollow out areas of materials, creating intricate designs and patterns. It is commonly used in woodworking, signage, and the fabrication of decorative elements.

CNC 3D Printing/Additive Manufacturing

CNC 3D printing, also known as additive manufacturing, builds 3D objects layer by layer using various materials. It finds applications in industries such as aerospace, medical, and product prototyping.

CNC Electrical Discharge Machining

CNC electrical discharge machining (EDM) shapes materials using electrical sparks. EDM is ideal for creating intricate details and complex forms in metals that are difficult to machine using traditional methods.

These different types of CNC operations showcase the versatility and precision of modern manufacturing processes. Each operation plays a vital role in various industries, enabling the production of high-quality and intricate components.

Benefits of CNC Technology

CNC technology revolutionizes the manufacturing industry by offering numerous benefits to businesses. Let’s explore some of its key advantages:

1. Cost Reduction

CNC machines play a crucial role in reducing costs for manufacturers. By automating production processes, CNC technology improves efficiency and scalability, leading to higher productivity and lower labor costs. Moreover, the precise control provided by CNC machines minimizes material waste, resulting in significant savings.

2. Improved Worker Safety

Worker safety is prioritized with the introduction of CNC technology. By automating tasks that involve heavy machinery and equipment, the risk of accidents and injuries is greatly reduced. CNC machines require minimal human interaction during operation, ensuring a safer working environment.

3. Human Error Reduction

CNC technology eliminates the possibility of human error, leading to enhanced precision, speed, and repeatability. With pre-programmed instructions, CNC machines consistently produce accurate and high-quality parts, reducing the need for manual intervention and ensuring consistent results.

4. Waste Reduction

CNC machines incorporate simulations and optimizations that help minimize waste during the manufacturing process. By optimizing tool paths and material utilization, CNC technology maximizes efficiency and reduces material waste, contributing to a more sustainable manufacturing process.

5. Contour Machining

One of the key advantages of CNC technology is its ability to perform contour machining, enabling the precise milling of complex and contoured shapes. This capability is particularly beneficial in industries such as aerospace, automotive, and medical, where intricate and customized parts are often required.

6. Faster MCU Programming

CNC systems integrated with CAD and CAM software enable faster programming of machine control units (MCUs). This integration streamlines the design-to-production process by automating the translation of CAD designs into machine-readable instructions. As a result, time-consuming programming tasks are reduced, allowing for faster production turnaround.

7. Improved Operational Intelligence

CNC technology, when integrated with enterprise resource planning (ERP) software, enhances operational intelligence. The integration facilitates real-time monitoring of production metrics, optimizing resource allocation, and improving overall operational efficiency. This data-driven approach enables businesses to make informed decisions and drive continuous improvement.

8. No Bottlenecks

CNC machines capable of automated production eliminate bottlenecks in the manufacturing process. With the ability to run continuously and efficiently, CNC technology ensures smooth and uninterrupted production, allowing businesses to meet deadlines and fulfill customer demands more efficiently.

As evident from the above benefits, CNC technology brings a multitude of advantages to manufacturers, ranging from cost reduction and waste reduction to improved worker safety and operational intelligence. The integration of CNC technology empowers businesses to thrive in today’s competitive manufacturing landscape.

Applications of CNC Technology

CNC technology plays a crucial role in various industries and sectors, enabling precise and efficient manufacturing processes. Let’s explore some of the key applications of CNC technology in different industries:

Aerospace

In the aerospace industry, CNC machines are extensively used to manufacture complex and high-precision components for aircraft and spacecraft. CNC technology ensures accuracy and consistency, meeting the stringent requirements of the aerospace sector.

Medical Equipment

CNC machines are instrumental in the production of medical equipment, especially during times of increased demand such as the COVID-19 pandemic. These machines enable the manufacturing of specialized and high-quality medical devices and components, contributing to the advancement of healthcare.

Automotive

CNC machining plays a vital role in the automotive industry for prototyping, mass production, and customization of parts. CNC machines enable the precise manufacturing of engine components, chassis parts, interior fittings, and more, fostering innovation and efficiency in the automotive sector.

Electronics

The electronics industry benefits greatly from CNC technology’s accuracy and adaptability. CNC machines are used to manufacture intricate and precise electronic components such as circuit boards, connectors, and housings. These machines ensure high-quality production and contribute to the advancement of electronic devices.

Oil and Gas

In the oil and gas industry, CNC technology is utilized for the production of precise parts used in drilling rigs, refineries, and offshore platforms. CNC machines enable the manufacturing of complex components with tight tolerances, ensuring optimal performance and safety in the oil and gas sector.

Marine

The marine industry relies on CNC machines for the production of highly precise parts that are essential for the smooth operation of ships and vessels. CNC technology enables the manufacturing of propellers, valves, pump components, and other critical marine parts, ensuring reliability and efficiency in maritime operations.

These are just a few examples of how CNC technology is applied in various industries. The versatility and precision of CNC machines make them indispensable in modern manufacturing, driving innovation and efficiency across sectors.

History of CNC Technology

The history of CNC technology traces back to the mid-20th century, with key advancements and milestones that have shaped modern manufacturing processes.

In the late 1940s and early 1950s, the first numerical control (NC) machines were developed. These early machines used punched paper tapes to control the movement of machine tools. While revolutionary at the time, they lacked the digital precision of modern CNC technology.

It was in the late 1950s that John T. Parsons and his team at the Massachusetts Institute of Technology (MIT) made a groundbreaking development. Parsons devised a method to control machine tools directly using digital data, marking a significant transition in CNC operations.

The commercialization of CNC machines gained momentum in the 1960s, making these cutting-edge technologies more accessible to manufacturers. With advancements in microprocessors and computer technology in the 1970s, CNC machines became more compact, affordable, and powerful.

One of the notable advancements in the 1980s was the integration of CNC machines with computer-aided design (CAD) and computer-aided manufacturing (CAM) software. This integration streamlined the design-to-production workflow, enabling seamless collaboration and increased efficiency.

Key Milestones in the History of CNC Technology:

| Year | Milestone |

|---|---|

| 1940s-1950s | Development of the first numerical control (NC) machines using punched paper tapes for machine tool control. |

| Late 1950s | John T. Parsons and his team at MIT develop a method for controlling machine tools directly using digital data. |

| 1960s | Commercialization of CNC machines. |

| 1970s | Advancements in microprocessors and computer technology make CNC machines more compact and affordable. |

| 1980s | Integration of CNC machines with CAD and CAM software for streamlined design-to-production processes. |

The history of CNC technology has seen continuous evolution and integration with other cutting-edge technologies. These advancements have revolutionized manufacturing processes, enabling greater precision, efficiency, and design freedom.

CNC Machine Programming

CNC machine programming plays a crucial role in turning CAD designs into machine-readable instructions. These instructions, known as G-code, dictate the precise movements, speed, and cutting actions of the CNC machine. The programming process requires precision and attention to detail to ensure accurate and consistent manufacturing.

There are two types of CNC systems: open-loop and closed-loop systems. Open-loop systems operate with one-way communication between the controller and motor, while closed-loop systems have feedback capabilities, allowing them to make real-time corrections. Closed-loop systems are preferred when high precision and accuracy are required.

When programming CNC machines, engineers create a part program that includes the necessary G-code instructions. The part program specifies the tooling, toolpath, cutting speeds, and any other relevant parameters. The G-code then guides the CNC machine in executing the programmed actions, resulting in the desired end product.

Table: Comparison of Open-Loop and Closed-Loop CNC Systems

| Open-Loop Systems | Closed-Loop Systems |

|---|---|

| One-way communication | Two-way communication with feedback |

| Less expensive | More expensive due to feedback components |

| No real-time error correction | Real-time error correction for greater accuracy |

| Suitable for less demanding applications | Ideal for high-precision manufacturing |

In summary, CNC machine programming is the vital process of translating CAD designs into machine-readable G-code instructions. This programming enables CNC machines to operate in both open-loop and closed-loop systems, with closed-loop systems offering real-time error correction and enhanced precision. By mastering CNC machine programming, manufacturers can achieve reliable and efficient manufacturing processes.

Future of CNC Technology

The future of CNC technology holds immense potential, driven by continuous advancements in machining capabilities and integration with other cutting-edge technologies. As industry demands evolve, CNC machines are expected to become more advanced, offering increased automation and seamless integration with artificial intelligence (AI).

One exciting development in the future of CNC technology is the integration with additive manufacturing, also known as 3D printing. This combination of technologies opens up new possibilities for precision manufacturing, enabling the creation of complex geometries and the production of intricate parts with exceptional accuracy.

With the integration of artificial intelligence, CNC machines will be able to analyze vast amounts of data, make real-time decisions, and optimize manufacturing processes. This integration will enhance production efficiency, reduce errors, and enable predictive maintenance, ultimately leading to improved productivity and cost savings.

Furthermore, the future of CNC technology will witness a significant increase in automation. CNC machines will be capable of performing a wide range of tasks with minimal manual intervention, streamlining operations and reducing human error. This automation will not only improve overall productivity but also create a safer working environment by minimizing the risk of accidents.