CNC (Computer Numerical Control) machining services are an essential part of the modern manufacturing process. CNC machining offers a wide range of benefits for businesses of all sizes, making it an increasingly popular choice for many industrial applications. CNC machining is a process which uses a computer controlled device to produce parts, components, and products from a wide range of materials. The process is highly automated and can be used to create complex shapes and intricate details with an extremely high degree of accuracy. This makes it ideal for producing parts that have tight tolerances and require precise measurements.

The accuracy of CNC machining also makes it a great choice for producing highly complex components, such as turbine blades or medical implants. The process also allows for the production of components with intricate features, such as threads, grooves, and even inlays. This allows for the production of parts that are both strong and aesthetically pleasing. CNC machining also offers a high degree of flexibility and customization, allowing businesses to create components that are perfectly suited to their needs. The process can be used to create parts with unique shapes, sizes, and configurations, allowing businesses to create parts that are ideal for their specific application.

Finally, CNC machining offers businesses a cost-effective solution to their manufacturing needs. The process is highly efficient and can reduce manufacturing costs significantly, allowing businesses to stay competitive in the global market. Overall, CNC machining services offer a range of benefits for businesses of all sizes. From precision and accuracy to flexibility and cost savings, CNC machining is an invaluable tool in the modern manufacturing process.

Benefits of CNC Machining Services for Manufacturing Companies

CNC machining services have become increasingly popular in recent years for their many benefits to manufacturing companies. CNC machining is a process that computer numeric control machines are programmed to complete a variety of automated machining tasks. The CNC machining process is more accurate and efficient than traditional machining methods, allowing manufacturers to produce higher quality products with fewer errors and in less time. One of the primary benefits of CNC machining services is that it significantly reduces waste and improves accuracy. CNC machines are programmed to follow the exact specifications of the product, resulting in fewer mistakes and less material wasted during the manufacturing process.

This helps to reduce costs and increase efficiency for the manufacturer. CNC machining also allows for greater flexibility in manufacturing. CNC machines are capable of producing complex parts that are difficult or impossible to make with traditional machining methods. This allows manufacturers to produce customized parts that meet exact specifications quickly and easily. Additionally, it enables manufacturers to produce parts with unique features, such as grooves, threads, or complex shapes. Moreover, CNC machining services can reduce the need for manual labor. CNC machines can be programmed to complete repetitive tasks quickly and accurately, reducing the amount of time required for manual labor. This allows manufacturers to reduce labor costs while producing higher quality products in less time.

Finally, CNC machining services are cost-effective. CNC machines require minimal maintenance and are relatively inexpensive to operate. This makes CNC machining an attractive option for manufacturers looking to maximize their profits while minimizing their costs. All in all, CNC machining services are a great option for manufacturing companies looking to reduce costs, improve efficiency, and create higher quality products. With its accuracy, flexibility, and cost-effectiveness, CNC machining is an excellent choice for any manufacturer.

Understanding the Process of CNC Machining for Precision Parts

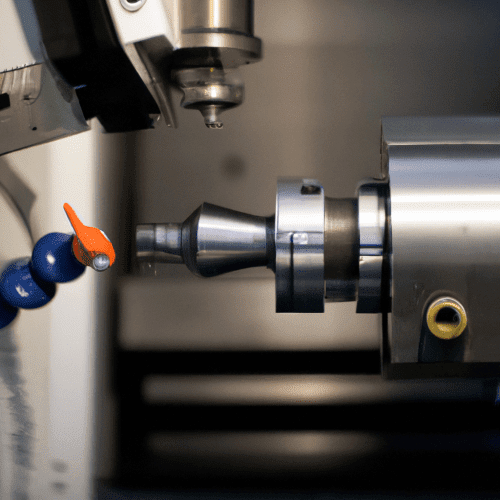

CNC machining is an advanced process used to produce precision parts, components, and tools. It is an automated process that uses computer numerical control (CNC) technology to operate a machine tool. The process involves the use of programmable controls and specialized software to precisely guide the machine tool and produce parts with a high degree of accuracy and repeatability. The process begins with the creation of a computer-aided design (CAD) file that includes the geometry of the part or component that needs to be machined. This file is then imported into a CNC controller that is connected to the machine tool. The CNC controller interprets the CAD file and uses the information to generate a series of instructions for the machine tool.

These instructions control the movement of the cutting tools, feed rates, spindle speeds, and other parameters as they relate to the machining process. Once the CNC controller has generated the instructions, the machine tool begins to cycle through the machining operation. The cutting tools are guided by the CNC controller to cut away material from the part until the desired shape and size is achieved. Depending on the complexity of the part, the machining process can involve multiple cycles and operations to produce the finished part. Throughout the machining process, the CNC controller monitors the machine tool and its cutting tools to ensure that the desired tolerances and specifications are met.

The CNC controller can also be programmed to make automated adjustments to the toolpath or cutting parameters if the machine tool begins to drift away from the desired tolerances. By utilizing CNC machining, manufacturers are able to produce parts with a high degree of accuracy and repeatability in a fraction of the time that would be required with traditional manufacturing methods. The process can also be used to produce complex geometries that are difficult or impossible to produce with manual processes.

How CNC Machining Services Increase Productivity and Efficiency

CNC machining services can be a valuable asset in any production facility, as they offer a number of advantages that can help increase productivity and efficiency. CNC stands for Computer Numerical Control, and it is a process that uses computers to control the movement of machine tools such as lathes, mills, routers, and grinders. CNC machining services utilize the computer to accurately control the movements of the cutting tools, ensuring precision and accuracy in the production of parts and components. The main benefit of CNC machining services is that they can significantly improve the speed of production and reduce the amount of time and labor required to complete a project. With CNC machining, parts and components can be produced quickly and accurately, reducing the need for manual labor and resulting in shorter lead times.

This increased speed and efficiency can help to reduce costs and improve the overall productivity of the production facility. Another advantage of CNC machining services is that they can reduce the risk of human error during the production process. Since the computers are controlling the cutting tools, the possibility of human error is greatly reduced, resulting in higher quality parts and components. CNC machining can also reduce the amount of scrap material generated during the production process, reducing costs and improving the overall efficiency of the production line. Finally, CNC machining services can help to improve the consistency of the parts and components produced. By using the same cutting tools and programming, the same exact parts and components can be produced each time, ensuring a consistent quality of products. This consistency helps to ensure that customers receive the same quality product each time they order, reducing customer complaints and increasing customer satisfaction.

Overall, CNC machining services can provide a number of advantages that help to increase productivity and efficiency in any production facility. By reducing the amount of manual labor and scrap material generated, reducing the risk of human error, and improving the consistency of the parts produced, CNC machining services can help to improve the overall efficiency of any production line.

The Advantages of Automated CNC Machining Services

Automated CNC machining services are becoming increasingly popular, and for good reason. Automated CNC machining services offer a variety of advantages over traditional non-automated machining processes, particularly when it comes to accuracy, repeatability, and cost savings. In this article, we will discuss the advantages of automated CNC machining services. One of the biggest advantages of automated CNC machining services is their high level of accuracy. Automated CNC machining services are able to produce parts with extremely tight tolerances since the machines are programmed using precise CAD/CAM software. This helps to ensure that parts produced are exactly as they should be and that no mistakes are made during production.

Another advantage of automated CNC machining services is their ability to replicate the same results over and over again. Once a program is written and the machine is set up, parts can be produced with the exact same specifications every time. This makes automated CNC machining services ideal for producing large quantities of identical parts. Finally, automated CNC machining services offer cost savings as well. Because the machines are programmed to produce parts quickly and accurately, there is less human labor involved. This can help to reduce the cost of labor and materials, resulting in a lower overall cost. Additionally, since the machines can run for extended periods of time without needing additional programming, they also help to reduce overhead costs. In conclusion, automated CNC machining services offer a variety of advantages over traditional non-automated machining processes.

These advantages include the ability to produce parts with high levels of accuracy, the ability to replicate the same results over and over again, and cost savings from reduced labor and material costs. For these reasons, automated CNC machining services are becoming increasingly popular.

Exploring the Different Types of CNC Machining Services Available

CNC machining is a method of manufacturing that uses computer numerical control (CNC) technology to create highly accurate components, parts, and tools. It is a popular choice for a wide range of industries, from automotive to medical, and is used to create components of all shapes and sizes. There are many different types of CNC machining services available, each with its own unique set of advantages and disadvantages. From the most basic milling and turning to more advanced processes such as wire erosion, waterjet cutting, and EDM (electrical discharge machining), there is a CNC machining solution for almost any application.

Milling is one of the most common types of CNC machining services. It is used to create complex shapes and features on materials such as metals, plastics, composites, and wood. Milling machines typically use rotary cutters to remove material from the workpiece. Turning is another form of CNC machining that can be used to create a variety of components. It is ideal for producing symmetrical parts with precise dimensions. The process typically involves the use of a lathe, which uses cutting tools to shape the workpiece as it rotates. Wire erosion is a type of CNC machining that uses an electrical current to erode a material. This process is often used to create intricate features and shapes on materials such as metal and plastic. It is ideal for applications where high precision is required. Waterjet cutting is a CNC machining process that uses a high-pressure stream of water to cut through materials.

This process is often used to create complex shapes and intricate features on materials such as metal, stone, and composites. EDM (electrical discharge machining) is a type of CNC machining that uses sparks of electricity to erode a material. EDM is ideal for creating intricate shapes and features on materials such as metal and plastic. These are just some of the different types of CNC machining services available. Each process has its own unique advantages and disadvantages, so it’s important to consider the specific needs of your application before deciding which one is right for you.