CNC (Computer Numerical Control) machining is a popular option for the production of parts due to its many advantages. CNC machining provides precise control over the entire machining process, allowing for the production of complex parts with a high degree of accuracy and repeatability. This type of machining also offers greater versatility and flexibility, allowing for the production of parts from a wide range of materials. Additionally, CNC machining is capable of producing parts with a wide range of surface finishes, from rough to highly polished, and can also be used to create intricate details and patterns. CNC machining also offers a number of cost benefits. Because the process is automated, the cost for producing parts is typically lower than with manual machining.

This cost savings is further enhanced by the reduced amount of material that is wasted, as CNC machining is able to produce parts with a high degree of accuracy, reducing scrap. Furthermore, CNC machining is capable of producing parts in a fraction of the time that it would take to produce them using manual machining. Overall, CNC machining is a cost-effective, efficient, and accurate method of producing parts. Its ability to produce parts with a high degree of precision, as well as with a variety of surface finishes and intricate details, makes it an attractive option for many applications.

Exploring the Benefits of CNC Machining for Parts Production

CNC machining is a process used to produce parts, components, and products from a variety of materials. This process is a combination of computer numerical control (CNC) and manual operations, such as drilling, milling, and turning. CNC machining has become increasingly popular in recent years due to its various advantages over traditional manufacturing processes. One of the primary benefits of CNC machining is its accuracy. The machine is programmed with precise coordinates, allowing it to accurately produce parts to exact specifications. This eliminates the need for manual operations such as filing and sanding, significantly reducing production time. Additionally, CNC machining is capable of producing complex parts with intricate geometries.

This allows for the production of parts that would be difficult or impossible to produce with traditional manufacturing processes. CNC machining is also highly efficient. The use of computers allows for a high degree of automation, resulting in a faster production rate and less waste. This is especially beneficial for high-volume production runs, where the cost savings can be significant. Additionally, CNC machining can be used with a variety of materials, allowing for greater flexibility in terms of product design. Finally, CNC machining offers greater safety than manual machining processes. Since the machine is operated by computer, there is no need for manual intervention and thus no risk of human error. This reduces the potential for accidents and injury. In conclusion, CNC machining is an ideal solution for parts production due to its accuracy, efficiency, and safety. The various benefits offered by CNC machining make it an attractive option for businesses in a wide range of industries.

The Precision and Accuracy of CNC Machining for Parts Manufacturing

CNC machining is a method of manufacturing parts and components that is becoming increasingly popular due to its ability to produce highly precise parts with high accuracy. CNC stands for Computer Numerical Control, and it involves the use of computer-controlled cutting tools to shape and fabricate parts from a variety of materials. CNC machining is often used to produce parts for a variety of industries, such as automotive, aerospace, medical, and electronics. CNC machining offers a number of advantages over traditional manufacturing methods, including higher accuracy and precision. Because the cutting tools are computer-controlled, the parts created through CNC machining are more precisely dimensioned and toleranced than those created through manual machining.

CNC machining also eliminates the need for manual calibration or adjustment of the cutting tools, which further increases the precision and accuracy of the finished product. Additionally, CNC machining can be used to produce complex shapes and curves that are difficult or impossible to achieve through manual machining. The accuracy and precision of CNC machined parts is determined by several factors, including the quality and precision of the cutting tools, the level of experience and skill of the machinist, and the quality of the CNC programming. The cutting tools used in CNC machining must be of high quality and properly maintained to ensure accurate, precise parts. The machinist’s level of experience and skill is also important in determining the accuracy and precision of CNC machined parts, as the machinist must have the knowledge and expertise to understand the CNC programming and operate the CNC machine efficiently.

Finally, the CNC programming must be of the highest quality, as even the most skillful machinist cannot overcome poor programming. In conclusion, CNC machining offers a number of advantages over traditional manufacturing methods, including improved accuracy and precision. By using high-quality cutting tools, experienced machinists, and high-quality CNC programming, CNC machining can produce parts with exceptional precision and accuracy.

The Cost-Effectiveness of CNC Machining for Parts Manufacturing

CNC machining is a process of cutting and shaping materials into complex shapes and designs utilizing computer numerical control (CNC) tools. This technology has revolutionized the manufacturing industry, allowing for the production of high-quality parts in large quantities in a fraction of the time and cost of traditional manufacturing methods. CNC machining is an increasingly popular option for parts manufacturing due to its cost-effectiveness, accuracy, and versatility. The cost-effectiveness of CNC machining for parts manufacturing is due in part to its time-saving capabilities.

By using CNC machines, parts can be machined in a fraction of the time it would take to produce them using traditional methods, reducing labor costs and improving productivity. CNC machining is also more accurate than traditional manufacturing methods, allowing for precise and repeatable results with minimal waste of materials. This increases efficiency and lowers costs, as fewer materials are required to produce a given part. In addition to its cost-effectiveness, CNC machining is highly versatile. CNC machines can be programmed to produce parts with a wide range of shapes and sizes, offering greater flexibility than traditional methods. This allows manufacturers to produce custom-made parts quickly and efficiently, further reducing costs.

Finally, CNC machining is an environmentally friendly process. CNC machines produce minimal waste and require fewer chemicals and hazardous materials than other manufacturing methods, resulting in fewer emissions and improved air quality. Overall, CNC machining is a cost-effective and efficient method for parts manufacturing. It offers time-saving capabilities, accuracy, versatility, and environmental benefits, making it an ideal choice for manufacturers looking to reduce costs and increase productivity.

The Versatility of CNC Machining for Parts Production

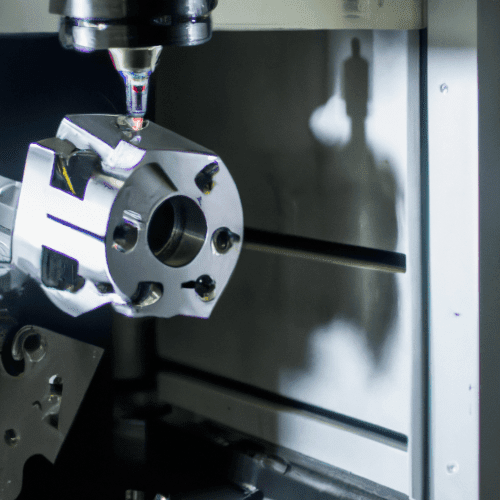

CNC (Computer Numerical Control) machining is a versatile process that is often used to produce parts of various shapes and sizes from a range of materials. It is a process that involves the use of computer-controlled machines and tools to shape materials into the desired design. The process is highly precise and efficient, enabling the production of parts with high accuracy and repeatability. CNC machining is a subtractive manufacturing process that starts with the raw material, which is then cut, shaped, and formed into the desired product. The process involves the use of high-speed cutting tools such as end mills and drills that are programmed by a computer to cut the material in a precise manner.

The tooling is mounted on a spindle that is controlled by the computer, ensuring that the cutting process is precise and accurate. The flexibility of CNC machining makes it an ideal choice for producing parts in various shapes and sizes. It is also well-suited for producing complex geometries and intricate features. With CNC machining, parts can be produced with tight tolerances, which is especially important for components used in industries such as aerospace, medical, and automotive. CNC machining is a cost-effective process that is capable of producing parts in large quantities. This makes it an ideal choice for production runs, as it is capable of producing large quantities of parts in short lead times. CNC machining is also easily scalable, enabling the production of both small and large parts. CNC machining can be used to produce parts from a wide range of materials, including plastics, metals, and composites. This makes it an ideal choice for many industries, as it is capable of producing parts from a variety of materials. The process is also capable of producing parts with complex geometries and intricate features, making it ideal for producing components with intricate designs.

Overall, CNC machining is a versatile process that is capable of producing parts in a variety of shapes and sizes from a range of materials. It is a cost-effective process that is capable of producing parts in large quantities with tight tolerances and intricate details. This makes it an ideal choice for production runs and for producing components with complex geometries.

The Time Savings of CNC Machining for Parts Production

CNC machining is an important production method in the manufacturing industry, allowing for significant time savings over traditional machining processes. By utilizing computer numerical control (CNC) machines, engineers are able to quickly produce complex parts with a high degree of accuracy and repeatability. In addition, CNC machining offers a number of other advantages that can help speed up the production process and improve the quality of finished parts. The primary benefit of CNC machining is the time savings it provides.

By utilizing CNC machines, engineers can quickly program the machine to produce parts from a variety of materials. This reduces the time required to manually set up the machine and create the parts from scratch, saving both time and money. Additionally, CNC machines are capable of producing parts with a high degree of accuracy and repeatability. This means that fewer parts need to be produced in order to achieve the desired results, resulting in a further time savings. CNC machining also offers a number of other advantages. For instance, CNC machines are capable of producing complex parts with a wide range of shapes and sizes. This can be especially helpful for parts that need to fit into tight spaces or have intricate designs. Additionally, CNC machines can produce parts with a high degree of surface finish, which can help reduce post-processing time and improve the overall quality of the finished product.

Overall, CNC machining offers a number of advantages that can help speed up the production process and improve the quality of parts. By utilizing CNC machines, engineers are able to quickly program the machine to produce parts from a variety of materials, resulting in significant time savings. Additionally, CNC machines are capable of producing parts with a high degree of accuracy and repeatability, reducing the amount of time required to achieve desired results. This helps reduce overall production time and improve the quality of finished parts.