The hardest metal drills are those made from cobalt and titanium alloys. Cobalt drills are made from a combination of cobalt, chromium, and tungsten, and are known for their extreme hardness and durability. They are often used in applications where high heat and pressure are present, such as drilling through hardened steel. Titanium drills are made from a combination of titanium and other metals, and are known for their extreme strength and resistance to wear and tear. They are often used in applications where high precision and accuracy are required, such as drilling through thin metal sheets. Both cobalt and titanium drills are more expensive than other types of drills, but they are also more durable and can handle more difficult drilling tasks.

What’s the hardest metal drill to?

The hardest metal drill to use is typically one made of tungsten carbide. Tungsten carbide is an extremely hard and dense material that is often used in industrial applications, such as cutting and drilling. It is much harder than other metals, such as steel, and is often used to drill through materials that are too hard for other metals to penetrate. Tungsten carbide drills are also more expensive than other metal drills, so they are usually reserved for more specialized applications. When using a tungsten carbide drill, it is important to use the correct speed and pressure to ensure that the drill does not overheat and break. Additionally, it is important to use a lubricant to reduce friction and heat buildup.

What is the strongest type of drill?

The strongest type of drill is typically considered to be a hammer drill. Hammer drills are designed to drill into hard materials such as concrete, brick, and stone. They use a combination of rotational force and a hammering action to break up the material and create a hole. Hammer drills are powered by an electric motor and have a special clutch that allows them to switch between rotational and hammering modes. The hammering action creates a lot of force, allowing the drill to penetrate even the toughest materials. Hammer drills are also equipped with a variety of drill bits, allowing them to be used for a variety of applications. They are often used in construction and renovation projects, as well as for drilling into hard surfaces such as concrete and stone.

What is the best drill to go through metal?

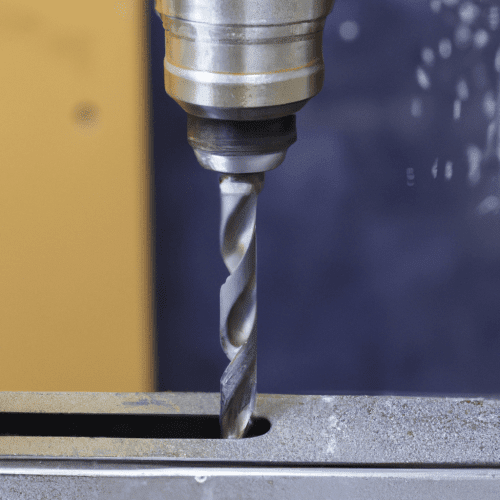

The best drill to go through metal depends on the type of metal and the size of the hole you need to make. Generally, a high-speed steel (HSS) twist drill bit is the best choice for drilling through metal. HSS bits are made of a combination of molybdenum and cobalt and are designed to cut through hard metals such as steel, stainless steel, and cast iron. They are also available in a variety of sizes and shapes, so you can choose the one that best fits your needs. When drilling through metal, it is important to use a lubricant such as cutting oil or WD-40 to reduce friction and heat. This will help to prevent the bit from becoming dull or overheating. Additionally, it is important to use a drill press or a drill stand to ensure that the hole is drilled straight and at the correct depth. Finally, it is important to use the correct speed and pressure when drilling through metal to ensure that the hole is clean and precise.

Which drill bit is harder cobalt or titanium?

The hardness of a drill bit is determined by its material composition and the heat treatment it has undergone. Cobalt drill bits are made from a combination of cobalt and steel, and are known for their hardness and durability. They are often used for drilling into hard metals such as stainless steel and titanium. Titanium drill bits are made from titanium and are known for their strength and resistance to wear. They are often used for drilling into softer materials such as aluminum and plastic.

When it comes to hardness, cobalt drill bits are generally considered to be harder than titanium drill bits. This is because cobalt drill bits are made from a combination of cobalt and steel, which makes them more durable and resistant to wear. Titanium drill bits, on the other hand, are made from titanium, which is a softer metal and therefore less resistant to wear.

Is cobalt stronger than titanium?

The answer to the question of whether cobalt is stronger than titanium depends on the context in which the question is being asked. Generally speaking, titanium is considered to be stronger than cobalt in terms of tensile strength, meaning that it can withstand greater amounts of stress before breaking. However, cobalt is often considered to be stronger than titanium in terms of hardness, meaning that it is more resistant to wear and tear. Additionally, cobalt is often considered to be more ductile than titanium, meaning that it can be bent and stretched more easily without breaking.

When it comes to specific applications, the answer to the question of which metal is stronger may vary. For example, in the aerospace industry, titanium is often used for its strength and light weight, while cobalt is used for its hardness and resistance to wear and tear. In the medical industry, cobalt is often used for its strength and ductility, while titanium is used for its light weight and corrosion resistance.

Can titanium drill bits go through hardened steel?

Yes, titanium drill bits can go through hardened steel. Hardened steel is a type of steel that has been heat treated to increase its strength and durability. It is much harder than regular steel and can be difficult to drill through. However, titanium drill bits are specifically designed to be able to drill through hardened steel. They are made from a special grade of titanium that is harder than regular steel and can withstand the high temperatures and pressures that are required to drill through hardened steel. Titanium drill bits also have a special coating that helps them to stay sharp and resist wear and tear. This makes them ideal for drilling through hardened steel.

Is titanium stronger than steel?

Titanium is a strong, lightweight metal that is often used in the aerospace industry and other applications where strength and low weight are important. It is about as strong as steel, but 45% lighter. It is also corrosion-resistant and has the highest strength-to-weight ratio of any metal. However, it is not as strong as steel in terms of tensile strength and compression strength. Steel is much stronger than titanium in terms of shear strength, which is the ability to resist forces that would cause the material to deform or break. Steel is also much more ductile than titanium, meaning it can be bent and shaped more easily. Titanium is also more expensive than steel, so it is not always the best choice for applications where strength is the primary concern.

Is there a metal stronger than titanium?

Titanium is a strong and lightweight metal that is used in a variety of applications, from aerospace to medical implants. It is known for its strength-to-weight ratio, corrosion resistance, and ability to withstand extreme temperatures. However, there are several metals that are stronger than titanium.

One of the strongest metals is tungsten, which has a tensile strength of 1,510 megapascals (MPa). This is almost double the strength of titanium, which has a tensile strength of 830 MPa. Tungsten is also extremely dense, with a density of 19.25 g/cm3, which is almost twice that of titanium (4.51 g/cm3). Tungsten is used in a variety of applications, including aerospace, military, and medical.

Another metal that is stronger than titanium is steel. Steel is an alloy of iron and carbon, and it has a tensile strength of 1,400 MPa. Steel is also much denser than titanium, with a density of 7.85 g/cm3.

What is the most difficult metal to weld?

Welding is a process of joining two pieces of metal together by melting them and using a filler material to form a strong bond. The difficulty of welding a particular metal depends on a variety of factors, including the type of metal, its thickness, and the welding process used. Generally speaking, some of the most difficult metals to weld include stainless steel, aluminum, magnesium, and titanium.

Stainless steel is a particularly difficult metal to weld because it is prone to cracking and warping due to its high chromium content. It also has a high thermal conductivity, which makes it difficult to maintain a consistent temperature during welding. Aluminum is also difficult to weld because it has a low melting point and is prone to oxidation. Magnesium is also difficult to weld because it is highly reactive and can easily ignite when exposed to heat. Finally, titanium is difficult to weld because it has a high melting point and is prone to cracking.