Yes, a CNC router can cut through wood. CNC routers are computer-controlled machines that are used to cut and shape a variety of materials, including wood. They are typically used in woodworking, furniture making, and other manufacturing applications. CNC routers are capable of cutting through wood with precision and accuracy, and can be used to create intricate designs and shapes.

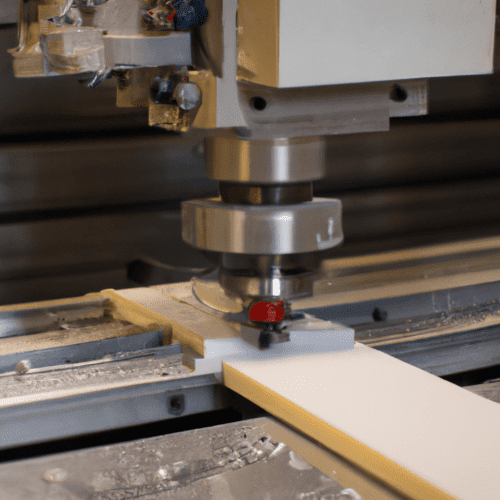

CNC routers use a variety of cutting tools, such as end mills, drill bits, and router bits, to cut through wood. The cutting tools are mounted on a spindle, which is driven by a motor. The motor is controlled by a computer, which is programmed with the desired cutting parameters. The cutting tools are then moved along the wood in a precise pattern, cutting out the desired shape.

CNC routers are capable of cutting through a variety of woods, including hardwoods, softwoods, and plywood. The type of wood and the thickness of the material will determine the type of cutting tool that is used. For example, a router bit is typically used to cut through hardwoods, while an end mill is used to cut through softer woods.

CNC routers are also capable of cutting through a variety of other materials, such as plastics, aluminum, and steel. The type of material and the thickness of the material will determine the type of cutting tool that is used. For example, a router bit is typically used to cut through plastics, while an end mill is used to cut through aluminum and steel.

CNC routers are a great tool for woodworking and other manufacturing applications. They are capable of cutting through wood with precision and accuracy, and can be used to create intricate designs and shapes.

How deep can a CNC router cut wood?

CNC routers can cut wood to a variety of depths depending on the type of wood and the size of the router. Generally, a CNC router can cut wood up to 3 inches deep, but this can vary depending on the type of wood and the size of the router. For example, a larger router can cut deeper than a smaller router, and harder woods require a larger router to cut deeper. Additionally, the type of bit used can also affect the depth of the cut. For example, a straight bit can cut deeper than a V-bit, and a down-cut bit can cut deeper than an up-cut bit.

In general, the depth of the cut is determined by the size of the router, the type of wood, and the type of bit used. The depth of the cut can range from a few millimeters to several inches, depending on the size of the router and the type of wood. For example, a large router can cut up to 3 inches deep into hardwoods, while a smaller router may only be able to cut a few millimeters into softer woods. Additionally, the type of bit used can also affect the depth of the cut, with down-cut bits being able to cut deeper than up-cut bits.

Overall, CNC routers can cut wood to a variety of depths depending on the type of wood and the size of the router. The depth of the cut can range from a few millimeters to several inches, depending on the size of the router and the type of wood. Additionally, the type of bit used can also affect the depth of the cut, with down-cut bits being able to cut deeper than up-cut bits.

What is pass depth CNC?

Pass depth CNC is a term used to describe the depth of a cut made by a CNC (Computer Numerical Control) machine. It is the distance between the surface of the material being cut and the bottom of the cut. The pass depth is determined by the cutting tool used, the material being cut, and the desired depth of the cut. The pass depth is important because it determines the amount of material that is removed from the workpiece. If the pass depth is too shallow, the cut may not be deep enough to achieve the desired result. If the pass depth is too deep, the cut may be too deep and cause damage to the workpiece. The pass depth also affects the speed of the cut, as a deeper cut requires more time to complete. The pass depth is typically set by the CNC operator, but can also be set automatically by the CNC machine.

Can wood be used in a CNC machine?

Yes, wood can be used in a CNC machine. CNC stands for Computer Numerical Control, and it is a type of machining process that uses computer-controlled tools to shape and cut materials. CNC machines are used to create a variety of products, from furniture to automotive parts. Wood is a popular material for CNC machining because it is relatively easy to work with and can be used to create a variety of shapes and sizes.

When using a CNC machine to work with wood, it is important to select the right type of wood for the project. Different types of wood have different properties, such as hardness, density, and grain. Hardwoods, such as oak and maple, are often used for CNC machining because they are strong and durable. Softwoods, such as pine and cedar, are also used for CNC machining, but they are not as strong and durable as hardwoods.

Once the type of wood has been selected, the CNC machine can be used to cut, shape, and finish the wood. The CNC machine uses a variety of tools, such as routers, saws, and drills, to cut and shape the wood. The CNC machine can also be used to sand and finish the wood, giving it a smooth, polished look.

CNC machining is a great way to create custom wood products, such as furniture, cabinets, and other items. It is also a great way to create intricate designs and patterns in wood. CNC machining is a cost-effective way to create high-quality wood products, and it is becoming increasingly popular for woodworking projects.

What is Plunge rate?

Plunge rate is a term used to describe the rate at which a company’s stock price falls. It is a measure of how quickly the stock price is dropping, and is usually expressed as a percentage. Plunge rate is an important indicator of a company’s financial health, as it can be used to gauge the company’s ability to withstand market volatility. A high plunge rate can indicate that the company is in financial trouble, while a low plunge rate can indicate that the company is doing well.

Plunge rate is calculated by taking the difference between the current stock price and the previous day’s closing price, and then dividing it by the previous day’s closing price. This gives the percentage change in the stock price over the course of one day. The plunge rate can be used to compare the performance of different stocks, as well as to track the performance of a single stock over time.

Plunge rate can also be used to identify potential buying opportunities. If a stock has a high plunge rate, it may indicate that the stock is undervalued and could be a good buy. Conversely, if a stock has a low plunge rate, it may indicate that the stock is overvalued and could be a good sell.

In summary, plunge rate is a measure of how quickly a company’s stock price is falling, and is an important indicator of a company’s financial health. It can be used to compare the performance of different stocks, as well as to identify potential buying and selling opportunities.

Can a CNC router cut plywood?

Yes, a CNC router can cut plywood. CNC routers are computer-controlled cutting machines that are used to cut a variety of materials, including wood, plastic, metal, and foam. Plywood is a type of wood that is made up of thin layers of wood veneer that are glued together. It is a popular material for furniture, cabinetry, and other woodworking projects.

CNC routers are capable of cutting plywood with precision and accuracy. The router is programmed with a computer-aided design (CAD) program, which allows the user to create a design that the router will follow. The router is then able to cut the plywood to the exact specifications of the design. The router can also be used to cut intricate shapes and patterns into the plywood.

CNC routers are also capable of cutting plywood at a variety of speeds and depths. The speed and depth of the cut can be adjusted depending on the type of plywood being cut and the desired result. The router can also be used to cut multiple pieces of plywood at once, which can save time and money.

Overall, CNC routers are a great tool for cutting plywood. They are capable of cutting the material with precision and accuracy, and they can be used to cut multiple pieces of plywood at once. They are also relatively easy to use and can be programmed with a CAD program.

How thick of wood can a router cut?

A router is a versatile tool that can be used to cut a variety of materials, including wood. The thickness of wood that a router can cut depends on the type of router being used, as well as the type of bit being used. Generally speaking, a router can cut wood up to 1-3/4 inches thick, depending on the type of router and bit being used. For example, a plunge router with a straight bit can cut up to 1-3/4 inches thick, while a fixed-base router with a straight bit can cut up to 1-1/2 inches thick. Additionally, a router with a spiral bit can cut up to 2 inches thick.

When cutting thicker wood, it is important to use a router with a powerful motor, as well as a sharp bit. Additionally, it is important to use a router with a large enough base to provide stability and support for the wood being cut. It is also important to use a router with a variable speed control, as this will allow you to adjust the speed of the router to match the type of wood being cut. Finally, it is important to use a router with a dust collection system, as this will help to keep the work area clean and free of debris.

How deep can I go with a router?

The depth to which you can go with a router depends on the type of router you are using. Generally speaking, routers are designed to be used in shallow depths, such as in a home or office environment. However, some routers are designed to be used in deeper depths, such as in industrial or commercial settings. For example, some industrial routers are designed to be used in depths up to 10 meters (33 feet).

In addition to the type of router you are using, the depth to which you can go with a router also depends on the environment in which it is being used. For example, if you are using a router in a wet environment, such as a swimming pool or a lake, you may need to use a router that is designed to be used in deeper depths. Similarly, if you are using a router in a dusty environment, such as a construction site, you may need to use a router that is designed to be used in deeper depths.

Finally, the depth to which you can go with a router also depends on the type of signal you are trying to transmit. For example, if you are trying to transmit a wireless signal, you may need to use a router that is designed to be used in deeper depths in order to ensure that the signal is strong enough to reach its intended destination.

In conclusion, the depth to which you can go with a router depends on the type of router you are using, the environment in which it is being used, and the type of signal you are trying to transmit.

Are CNC routers worth it?

CNC routers are computer-controlled cutting machines used to create shapes and designs from a variety of materials. They are used in a variety of industries, from woodworking to automotive manufacturing. CNC routers are a great investment for businesses that need to produce high-quality, precise parts quickly and efficiently.

The main benefit of CNC routers is their accuracy and repeatability. CNC routers are programmed to cut parts with a high degree of precision, which is essential for many industries. CNC routers can also be programmed to cut multiple parts at once, which can save time and money. Additionally, CNC routers can be used to cut a variety of materials, including wood, plastic, metal, and composites.

CNC routers are also relatively easy to use. They are typically operated by a computer, which allows for easy programming and operation. Additionally, CNC routers are relatively low maintenance, as they require minimal upkeep and maintenance.

Overall, CNC routers are a great investment for businesses that need to produce high-quality, precise parts quickly and efficiently. They are accurate, repeatable, and can be used to cut a variety of materials. Additionally, they are relatively easy to use and require minimal maintenance. For these reasons, CNC routers are definitely worth the investment.

What are the advantages of a CNC router?

A CNC router is a computer-controlled cutting machine used to cut a variety of materials, such as wood, plastic, foam, and metal. CNC routers are used in a variety of industries, including woodworking, metalworking, and plastics manufacturing. CNC routers offer a number of advantages over traditional cutting methods, such as increased accuracy, repeatability, and speed.

One of the primary advantages of a CNC router is its accuracy. CNC routers are able to cut materials with a high degree of precision, which is not possible with traditional cutting methods. This accuracy allows for the production of parts with tight tolerances and intricate designs. CNC routers are also able to cut complex shapes with ease, which is not possible with traditional cutting methods.

Another advantage of a CNC router is its repeatability. CNC routers are able to produce identical parts with a high degree of accuracy. This repeatability allows for the production of parts with consistent quality and performance. CNC routers are also able to produce parts with complex shapes and intricate details, which is not possible with traditional cutting methods.

The speed of a CNC router is another advantage. CNC routers are able to cut materials at a much faster rate than traditional cutting methods. This increased speed allows for the production of parts in a shorter amount of time, which can result in cost savings.

Finally, CNC routers are able to cut a variety of materials with ease. CNC routers are able to cut wood, plastic, foam, and metal with ease, which is not possible with traditional cutting methods. This versatility allows for the production of parts with a variety of materials, which can result in cost savings.

Overall, CNC routers offer a number of advantages over traditional cutting methods, such as increased accuracy, repeatability, speed, and versatility. These advantages make CNC routers an ideal choice for a variety of industries, such as woodworking, metalworking, and plastics manufacturing.

What is the difference between a CNC router and a CNC mill?

The primary difference between a CNC router and a CNC mill is the type of cutting tool they use. A CNC router typically uses a spinning router bit to cut materials, while a CNC mill uses a rotating end mill to cut materials. CNC routers are generally used for cutting softer materials such as wood, plastic, and foam, while CNC mills are used for cutting harder materials such as metal and aluminum.

CNC routers are also typically smaller and more lightweight than CNC mills, making them easier to move and transport. CNC routers are also typically less expensive than CNC mills, making them a more cost-effective option for smaller projects.

CNC routers are also typically easier to use than CNC mills, as they require less setup and programming. CNC routers are also typically more accurate than CNC mills, as they are able to cut more precise shapes and patterns.

In terms of speed, CNC mills are typically faster than CNC routers, as they are able to cut harder materials more quickly. CNC mills are also able to cut deeper into materials than CNC routers, making them better suited for larger projects.

Overall, CNC routers and CNC mills are both powerful tools that can be used to create a variety of products. The type of tool you choose will depend on the type of material you are cutting, the size of the project, and the accuracy and speed you need.

What wood is good for CNC router?

When it comes to CNC routing, the type of wood you use is important. Different woods have different properties that make them better suited for certain applications. Generally, hardwoods are the best choice for CNC routing because they are strong and durable. Some of the most popular hardwoods for CNC routing include oak, maple, cherry, walnut, and mahogany. Softwoods, such as pine, are not as strong and durable as hardwoods, so they are not typically used for CNC routing.

When selecting a wood for CNC routing, it is important to consider the type of project you are working on. For example, if you are making a cabinet, you may want to use a hardwood such as oak or maple. If you are making a toy, you may want to use a softer wood such as pine. It is also important to consider the finish you want to achieve. Some woods, such as cherry, are better suited for staining, while others, such as walnut, are better suited for painting.

In addition to the type of wood, it is also important to consider the grain of the wood. The grain of the wood will affect the way the CNC router cuts the wood. For example, if you are using a wood with a tight grain, such as cherry, the CNC router will have an easier time cutting the wood. On the other hand, if you are using a wood with a loose grain, such as pine, the CNC router may have a harder time cutting the wood.

Finally, it is important to consider the cost of the wood. Hardwoods tend to be more expensive than softwoods, so if you are on a budget, you may want to consider using a softwood such as pine. However, if you are looking for a high-quality finish, you may want to invest in a hardwood such as oak or maple.

Overall, when selecting a wood for CNC routing, it is important to consider the type of project you are working on, the finish you want to achieve, the grain of the wood, and the cost of the wood. Hardwoods such as oak, maple, cherry,

Is wood easy to machine?

Wood is generally considered to be a relatively easy material to machine. It is a soft material that is easy to cut and shape, and it is also relatively inexpensive compared to other materials. Wood is also relatively easy to sand and finish, making it a popular choice for many projects.

Wood is also relatively easy to join together using various methods such as nails, screws, and glue. This makes it a great choice for projects that require multiple pieces to be joined together.

Wood is also relatively easy to paint and stain, making it a great choice for projects that require a decorative finish.

Overall, wood is a great material to work with and is relatively easy to machine. It is a versatile material that can be used for a variety of projects, and it is also relatively inexpensive compared to other materials.

Is MDF good for CNC carving?

MDF (medium-density fiberboard) is a popular material for CNC carving due to its affordability, availability, and ease of use. It is a composite material made from wood fibers and resin, and is available in a variety of thicknesses and sizes. MDF is a great material for CNC carving because it is relatively soft and easy to work with, and it can be cut into intricate shapes with a CNC machine. It is also relatively inexpensive compared to other materials, making it a great choice for projects that require a lot of material.

MDF is not the best material for CNC carving, however, as it is not as strong or durable as other materials such as hardwoods or aluminum. It is also prone to chipping and splintering, so it is important to use the correct cutting tools and speeds when working with MDF. Additionally, MDF is not waterproof, so it is not suitable for outdoor projects.

Overall, MDF is a great material for CNC carving due to its affordability, availability, and ease of use. However, it is important to consider the limitations of MDF when deciding whether or not it is the right material for a project.

Can CNC cut metal?

Yes, CNC (Computer Numerical Control) machines can cut metal. CNC machines are automated machines that use computer-controlled programs to cut and shape materials, including metal. CNC machines are used in a variety of industries, including automotive, aerospace, and medical, to create precision parts and components.

CNC machines use a variety of cutting tools to cut metal, including end mills, drills, and reamers. The cutting tool is mounted on a spindle, which is driven by a motor. The motor is controlled by a computer program, which determines the speed and direction of the cutting tool. The cutting tool is then moved along the surface of the metal, cutting away material to create the desired shape.

CNC machines can be used to cut a variety of metals, including aluminum, steel, stainless steel, brass, and copper. The type of metal being cut will determine the type of cutting tool used, as well as the speed and feed rate of the cutting tool. The cutting tool must be able to withstand the heat generated by the cutting process, as well as the hardness of the metal being cut.

CNC machines are used in a variety of industries to create precision parts and components. They are used to create parts for cars, airplanes, medical devices, and other products. CNC machines are also used to create custom parts and components for a variety of applications. CNC machines are highly accurate and can produce parts with tight tolerances. They are also capable of producing complex shapes and designs.