A CNC (Computer Numerical Control) machine is a type of automated machine tool that uses computer-controlled instructions to produce parts and components with high precision and accuracy. CNC machines are used in a variety of industries, including aerospace, automotive, medical, and consumer products. With a CNC machine, you can create a wide range of products, from simple parts to complex components.

Some of the most common items that can be made with a CNC machine include:

• 3D printed parts and components: CNC machines are often used to create 3D printed parts and components, such as prototypes, molds, and end-use parts.

• Machined parts and components: CNC machines can be used to create machined parts and components, such as gears, shafts, and other complex components.

• Sheet metal parts and components: CNC machines can be used to create sheet metal parts and components, such as brackets, enclosures, and other metal components.

• Wood parts and components: CNC machines can be used to create wood parts and components, such as furniture, cabinets, and other wood products.

• Plastic parts and components: CNC machines can be used to create plastic parts and components, such as injection molded parts, 3D printed parts, and other plastic components.

• Metal parts and components: CNC machines can be used to create metal parts and components, such as machined parts, sheet metal parts, and other metal components.

In addition to these items, CNC machines can also be used to create a variety of other products, such as signs, engravings, and other custom products. With the right software and tools, CNC machines can be used to create almost any type of product imaginable.

What projects can you do with a CNC router?

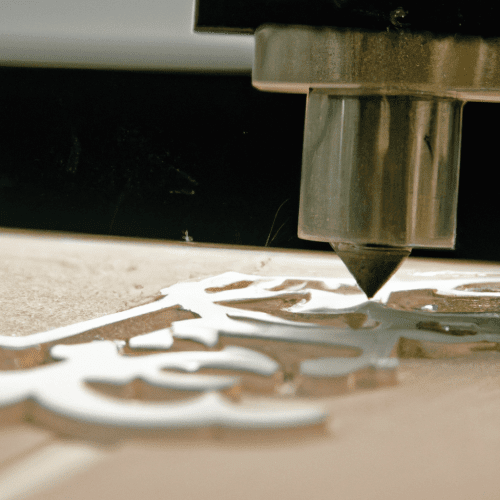

A CNC router is a computer-controlled cutting machine used to cut a variety of materials, such as wood, plastic, foam, and metal. It is a versatile tool that can be used to create a wide range of projects, from furniture and cabinetry to signs and sculptures.

One of the most common projects that can be done with a CNC router is cutting out parts for furniture. The router can be used to cut out the parts for chairs, tables, cabinets, and other furniture pieces. The router can also be used to cut out intricate designs, such as inlays and carvings, which can be used to add a unique touch to furniture pieces.

CNC routers can also be used to create signs and other decorative pieces. The router can be used to cut out letters and shapes from a variety of materials, such as wood, plastic, and metal. These pieces can then be painted or stained to create a unique sign or decorative piece.

What is CNC good for?

Computer Numerical Control (CNC) is a technology that uses computers to control machine tools such as lathes, mills, routers, and grinders. CNC machines are used to create precision parts and components with a high degree of accuracy. CNC machines are used in a variety of industries, including aerospace, automotive, medical, and consumer products.

CNC machines are advantageous because they can produce parts with a high degree of accuracy and repeatability. This is because the machines are programmed with a set of instructions that are followed precisely. CNC machines can also be programmed to produce parts with complex shapes and intricate details. This makes them ideal for producing parts with complex geometries and intricate details.

CNC machines are also advantageous because they can be used to produce parts quickly and efficiently. CNC machines can be programmed to produce parts in a fraction of the time it would take to produce them manually. This makes them ideal for producing large quantities of parts in a short amount of time.

How hard is it to be a CNC programmer?

Being a CNC programmer can be a challenging but rewarding career. It requires a great deal of knowledge and skill to be successful. CNC programming involves writing code that instructs a computer numerical control (CNC) machine to perform a specific task. This code must be written in a specific language, such as G-code, and must be precise and accurate.

In order to become a CNC programmer, one must have a strong understanding of mathematics, physics, and computer programming. A CNC programmer must also be familiar with the various types of CNC machines and their capabilities. They must also be able to read and interpret blueprints and technical drawings.

CNC programming requires a great deal of problem-solving skills and the ability to think logically. A CNC programmer must be able to troubleshoot and debug any issues that arise during the programming process. They must also be able to work with a variety of materials and be able to adjust the programming to accommodate different materials.

Are CNC routers worth it?

CNC routers are computer-controlled cutting machines used to create shapes and designs from a variety of materials. They are used in a variety of industries, from woodworking to aerospace, and can be used to create complex shapes and designs with precision and accuracy. Whether or not a CNC router is worth it depends on the individual’s needs and budget.

For those who need to create complex shapes and designs with precision and accuracy, a CNC router can be a great investment. CNC routers are capable of creating intricate shapes and designs with a high degree of accuracy and repeatability. This makes them ideal for creating complex parts and components for a variety of industries. Additionally, CNC routers are relatively easy to use and can be programmed to create a variety of shapes and designs with minimal effort.

On the other hand, CNC routers can be expensive. Depending on the size and capabilities of the machine, they can cost anywhere from a few thousand dollars to tens of thousands of dollars.

Can you really make money with CNC router?

Yes, you can make money with a CNC router. CNC routers are computer-controlled cutting machines that can be used to cut a variety of materials, including wood, plastic, metal, and foam. They are used in a variety of industries, including furniture making, sign making, and prototyping. With a CNC router, you can create custom parts, furniture, signs, and other products that can be sold for a profit.

CNC routers are relatively easy to use and can be used to create a wide variety of products. They are also relatively affordable, making them a great option for small businesses and entrepreneurs. With a CNC router, you can create custom products that can be sold for a profit. You can also use a CNC router to create prototypes for products that can be sold to larger companies.

In addition to creating products to sell, you can also use a CNC router to create custom parts for other businesses. For example, you can create custom parts for furniture makers, sign makers, and other businesses.

What is the average profit margin for machine shop?

The average profit margin for a machine shop can vary greatly depending on the type of services offered, the size of the shop, and the industry in which it operates. Generally speaking, the average profit margin for a machine shop is between 5-15%. This range is based on the average gross profit margin for the manufacturing industry as a whole, which is typically between 10-20%.

The type of services offered by a machine shop can have a significant impact on its profit margin. For example, a shop that specializes in custom machining services may have a higher profit margin than a shop that offers more general machining services. Additionally, the size of the shop can also affect its profit margin. Smaller shops may have higher profit margins due to their lower overhead costs, while larger shops may have lower profit margins due to their higher overhead costs.

The industry in which a machine shop operates can also have an impact on its profit margin. For example, a shop that operates in the aerospace industry may have a higher profit margin than a shop that operates in the automotive industry.

What do machine shops make?

Machine shops are manufacturing facilities that specialize in the machining of metal parts. They use a variety of tools and machines to cut, shape, and form metal into the desired shape or size. Machine shops typically use lathes, milling machines, drill presses, and other specialized equipment to create parts for a variety of industries, including automotive, aerospace, medical, and industrial.

The parts created by machine shops can range from simple components such as screws and bolts to complex parts such as engine blocks and turbine blades. Machine shops can also create custom parts for specific applications, such as medical implants or aerospace components.

In addition to machining metal parts, machine shops can also provide services such as heat treating, welding, and finishing. Heat treating is a process used to strengthen metal parts by heating and cooling them in a controlled environment. Welding is a process used to join two pieces of metal together, while finishing is a process used to give metal parts a smooth, polished look.

Can you make money with a Shapeoko?

Yes, it is possible to make money with a Shapeoko. Shapeoko is a desktop CNC (Computer Numerical Control) machine that is used to cut and shape materials such as wood, plastic, and metal. It is a popular tool for hobbyists, makers, and small businesses.

Shapeoko can be used to create a variety of products, from furniture to jewelry to custom parts. It can be used to create custom signs, engrave logos, and even create 3D models. With the right materials and tools, it is possible to create products that can be sold for a profit.

Shapeoko can also be used to create custom parts for larger projects. For example, it can be used to create custom parts for cars, boats, and other vehicles. It can also be used to create custom parts for industrial machinery. By creating custom parts, businesses can save money on production costs and increase their profits.