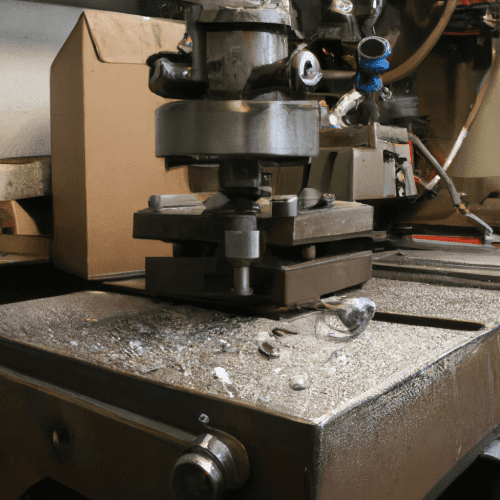

A milling machine is a versatile tool used in a variety of industrial and manufacturing applications. It is used to shape and cut materials such as metal, wood, and plastic. It can be used to create complex shapes, drill holes, and create slots. It can also be used to create intricate patterns and designs.

Milling machines are used in a variety of industries, including automotive, aerospace, medical, and electronics. They are used to create parts for engines, turbines, and other mechanical components. They are also used to create parts for medical devices, such as prosthetics and implants.

Milling machines can be used to create a variety of shapes and sizes. They can be used to create flat surfaces, curved surfaces, and complex shapes. They can also be used to create slots, grooves, and other features.

Milling machines can also be used to create intricate patterns and designs. They can be used to create decorative patterns on metal, wood, and plastic. They can also be used to create intricate designs on jewelry and other items.

Milling machines can also be used to create precision parts. They can be used to create parts with tight tolerances and precise dimensions. They can also be used to create parts with complex shapes and features.

Milling machines can also be used to create molds and dies. They can be used to create molds for injection molding, casting, and other manufacturing processes. They can also be used to create dies for stamping and other metalworking processes.

Milling machines can also be used to create prototypes and models. They can be used to create prototypes for testing and evaluation. They can also be used to create models for marketing and promotional purposes.

Which type of machining can be done by milling machine?

Milling machines are a type of machine tool used for machining solid materials such as metal, wood, and plastic. They are typically used to shape and finish components by cutting away excess material in a precise manner. Milling machines can be used to perform a wide variety of operations, including facing, slotting, drilling, reaming, boring, and tapping. They can also be used to create complex shapes and contours, as well as to produce intricate patterns and designs. Milling machines are capable of performing a variety of operations, including facing, slotting, drilling, reaming, boring, and tapping. They can also be used to create complex shapes and contours, as well as to produce intricate patterns and designs. Additionally, milling machines can be used to cut threads, create keyways, and perform other specialized operations.

What are the three 3 limitations of a milling machine?

Milling machines have several limitations when compared to other machining tools. The three main limitations are:

1. Size: Milling machines are limited in size and power, and are not suitable for machining large or heavy parts. They are also limited in the size of the cutting tools they can use, which limits the complexity of the parts they can produce.

2. Accuracy: Milling machines are not as accurate as other machining tools, such as lathes or CNC machines. This is due to the fact that the cutting tools used in milling machines are relatively large and have a limited range of motion.

3. Speed: Milling machines are relatively slow compared to other machining tools. This is due to the fact that the cutting tools used in milling machines are relatively large and have a limited range of motion. Additionally, the cutting tools used in milling machines are relatively slow compared to other machining tools.

Can a milling machine be used for boring?

Yes, a milling machine can be used for boring. Boring is the process of enlarging a hole that has already been drilled or cast, by means of a single-point cutting tool (or of a boring head containing several such tools), for example as in boring a gun barrel or an engine cylinder. Milling machines are very versatile and can be used to perform a variety of operations, including boring. Boring on a milling machine is performed using a boring head, which is a type of tool that is mounted on the spindle of the milling machine. The boring head is equipped with a cutting tool that is used to enlarge existing holes with precision and accuracy. The boring head can be adjusted to produce holes of different sizes and depths, and can be used to bore holes in a variety of materials, including metal, wood, and plastic.

What is need of milling machine?

Milling machines are essential tools used in industrial and manufacturing settings for a variety of tasks. They are used to shape and cut materials such as metal, wood, and plastic, and are used to create a variety of components and parts for machines, tools, and other products. Milling machines are also used to create custom parts and components for a variety of applications.

Milling machines are used to shape and cut materials into a variety of shapes and sizes. They are used to create components and parts for machines, tools, and other products. Milling machines are used to create custom parts and components for a variety of applications. They are used to create components for automotive, aerospace, medical, and other industries.

Milling machines are used to create a variety of shapes and sizes. They are used to create components and parts for machines, tools, and other products. Milling machines are used to create custom parts and components for a variety of applications. They are used to create components for automotive, aerospace, medical, and other industries.

What is the difference between a lathe and a milling machine?

A lathe and a milling machine are both used in manufacturing, but they have very different functions. A lathe is a machine tool that rotates a workpiece about an axis of rotation to perform various operations such as cutting, sanding, knurling, drilling, or deformation. It is used to shape metal, wood, or other materials. A milling machine is a machine tool used to machine solid materials. It uses a rotating cutting tool to remove material from the workpiece in a variety of directions. It can be used to drill, bore, cut gears, and produce slots.

The main difference between a lathe and a milling machine is the way in which they cut material. A lathe uses a single-point cutting tool to cut material, while a milling machine uses a multi-point cutting tool to cut material. A lathe is used to shape a workpiece by rotating it against a cutting tool, while a milling machine is used to shape a workpiece by moving the cutting tool across the workpiece in various directions.

What are the type of milling?

Milling is a machining process that uses a rotating cutting tool to shape and form materials such as metal, wood, and plastic. It is one of the most commonly used processes in manufacturing and is used to create a variety of shapes and components. There are several different types of milling processes, each of which has its own advantages and disadvantages.

The most common type of milling is end milling, which is used to create flat surfaces, slots, and contours. End mills are typically used on vertical milling machines, but can also be used on horizontal machines. End mills are available in a variety of shapes and sizes, and can be used to create a variety of shapes and components.

Face milling is another type of milling process that is used to create flat surfaces. Face mills are typically used on horizontal milling machines and are available in a variety of shapes and sizes. Face mills are used to create flat surfaces on a variety of materials, including metal, wood, and plastic.

What is milling machine Mcq?

A milling machine is a machine tool used for the shaping of metal and other solid materials. It typically uses a rotating cutting tool to shape and form the material into a desired shape or size. Milling machines can be used to perform a variety of operations, including drilling, boring, cutting, routing, and grinding. They can also be used to produce complex shapes and contours. Milling machines are used in a variety of industries, including automotive, aerospace, medical, and industrial manufacturing. They are also used in the production of precision parts and components.

Milling machines are typically classified according to the number of axes they have. The most common types are vertical milling machines, horizontal milling machines, and combination milling machines. Vertical milling machines have a vertical spindle that moves the cutting tool up and down. Horizontal milling machines have a horizontal spindle that moves the cutting tool side to side. Combination milling machines have both a vertical and a horizontal spindle, allowing for more complex operations.

How many types of milling process are there?

Milling is a machining process that uses a rotating cutting tool to remove material from a workpiece. There are several different types of milling processes, each of which has its own advantages and disadvantages. The most common types of milling processes are peripheral milling, face milling, end milling, and contour milling.

Peripheral milling is a process in which the cutting tool moves along the circumference of the workpiece. This type of milling is used to create slots, grooves, and other features on the outer surface of the workpiece. It is also used to create flat surfaces on the workpiece.

Face milling is a process in which the cutting tool moves perpendicular to the surface of the workpiece. This type of milling is used to create flat surfaces on the workpiece. It is also used to create slots, grooves, and other features on the surface of the workpiece.

Which type of process the machining can be?

Machining is a manufacturing process in which parts are cut from a workpiece using a variety of tools. It is a subtractive process, meaning that material is removed from the workpiece to create the desired shape. Machining can be used to create a variety of shapes and sizes, from simple to complex. It is used in a wide range of industries, from automotive to aerospace.

The type of process used in machining depends on the material being machined and the desired outcome. Common machining processes include turning, milling, drilling, grinding, and broaching. Each process has its own advantages and disadvantages, and the type of process used will depend on the application.

Turning is a process in which a rotating tool is used to cut material from a workpiece. It is used to create cylindrical shapes and is often used to create parts with a uniform diameter.

Milling is a process in which a rotating tool is used to cut material from a workpiece. It is used to create a variety of shapes, including flat surfaces, slots, and grooves.