Machining is a manufacturing process in which a material is cut into a desired shape and size by a controlled material-removal process. It is typically used to create parts with complex geometries and high precision. Machining is used in a variety of industries, including aerospace, automotive, medical, and consumer products. The process involves the use of a variety of tools, such as lathes, milling machines, drill presses, and grinders, to shape and cut the material. The material is typically held in place by a fixture, and the tools are guided by a computer numerical control (CNC) system. The CNC system is programmed with the desired shape and size of the part, and the tools are then used to cut the material to the desired shape and size. The machining process can be used to create parts from a variety of materials, including metals, plastics, and composites. The process can also be used to create parts with complex geometries, such as those used in aerospace and medical applications. Machining is a cost-effective way to produce parts with high precision and accuracy.

Whats the meaning of machining?

Machining is a manufacturing process in which parts are cut from a raw material using a variety of tools and machines. It is a subtractive process, meaning that material is removed from the workpiece to create the desired shape. Machining is used to create parts with complex shapes and features, such as those found in aircraft engines, medical implants, and automotive components. It is also used to create parts with precise dimensions and tolerances, such as those found in precision instruments and medical devices. Machining is a versatile process that can be used to create a wide variety of parts from a variety of materials, including metals, plastics, and composites. It is also used to create parts with a variety of finishes, such as polished, anodized, and painted.

What does machining mean in engineering?

Machining is a term used in engineering to refer to the process of cutting, shaping, and finishing materials to create a desired product. It is a subtractive manufacturing process, meaning that material is removed from a workpiece to create the desired shape. Machining is used to create parts for a variety of industries, including automotive, aerospace, medical, and consumer products.

The most common machining processes include turning, milling, drilling, grinding, and sawing. Turning is the process of rotating a workpiece on a lathe to create a cylindrical shape. Milling is the process of using a milling machine to cut and shape a workpiece. Drilling is the process of using a drill to create a hole in a workpiece. Grinding is the process of using an abrasive wheel to shape and finish a workpiece. Sawing is the process of using a saw to cut a workpiece.

In addition to these processes, machining also includes other processes such as broaching, honing, and lapping.

Why is machining needed?

Machining is a process used to shape and finish materials such as metals, plastics, and composites. It is used to create parts with precise dimensions and shapes, and to produce a variety of surface finishes. Machining is necessary because it allows for the production of parts with very precise tolerances and shapes that would be difficult or impossible to achieve with other manufacturing processes. It is also used to create complex shapes and features that would be difficult to produce with other processes. Machining is also used to produce parts with a variety of surface finishes, such as smooth, textured, and polished surfaces. Machining is also used to produce parts with a variety of finishes, such as anodized, painted, and plated finishes. Finally, machining is used to produce parts with a variety of materials, such as aluminum, steel, brass, and plastic.

What does machining mean in business?

Machining in business is the process of using specialized tools and machines to shape and cut materials into desired shapes and sizes. It is a manufacturing process that involves the use of cutting tools to remove material from a workpiece in order to create a desired shape or size. Machining is used in a variety of industries, including automotive, aerospace, medical, and industrial.

The most common type of machining is metalworking, which involves cutting, drilling, grinding, and other processes to shape metal into desired shapes and sizes. Machining can also be used to shape other materials, such as plastics, wood, and composites. Machining is often used in the production of parts for machines, vehicles, and other products.

The machining process typically begins with the selection of the appropriate tool and machine for the job. The tool is then set up and adjusted to the desired specifications. The material is then placed in the machine and the cutting process begins.

What is another word for machining?

Machining is a process used in manufacturing to shape and cut materials into a desired form. It is a subtractive process, meaning that material is removed from the workpiece to create the desired shape. Machining is often used in the production of parts for machines, tools, and other components. Another word for machining is metalworking, which is a broad term that encompasses a variety of processes used to shape and cut metal. Metalworking includes machining, as well as other processes such as forging, casting, and welding. Metalworking is used to create a variety of products, from tools and machines to jewelry and art.

What is machining example?

Machining is a manufacturing process in which a material is cut into a desired shape and size by a controlled material-removal process. It is one of the most common manufacturing processes, and is used to create parts with complex shapes and features. Examples of machining processes include turning, milling, drilling, grinding, and broaching.

Turning is a machining process in which a cutting tool, typically a non-rotary tool bit, is used to remove material from a workpiece to create a desired shape and size. The cutting tool is typically held in a tool holder and rotated at a high speed, while the workpiece is held in a chuck and rotated at a slower speed. The cutting tool is then fed into the workpiece, removing material from the workpiece in the form of chips.

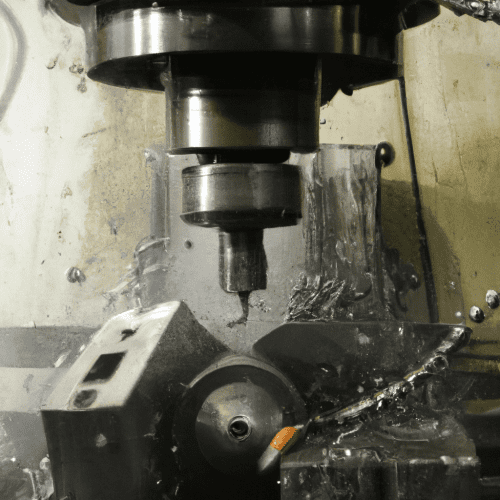

Milling is a machining process in which a rotating cutting tool is used to remove material from a workpiece to create a desired shape and size.

Is there such a word as machining?

Yes, there is such a word as machining. Machining is a process in which material is removed from a workpiece using a variety of tools and machines. It is a process that is used to shape and finish components and products. Machining is used in a variety of industries, including automotive, aerospace, medical, and manufacturing. It is used to create parts for machines, tools, and other products. Machining can be done manually or with the help of computer numerical control (CNC) machines. Manual machining involves the use of hand tools such as drills, lathes, and milling machines. CNC machining involves the use of computer-controlled machines that are programmed to perform specific tasks. Machining is used to create parts with precise dimensions and tolerances. It is also used to create complex shapes and features that would be difficult to achieve with other methods. Machining is an important part of the manufacturing process and is used to create parts for a variety of products.

What is machining and fabrication?

Machining and fabrication are two processes used to create parts and components from raw materials. Machining is a subtractive manufacturing process that involves cutting away material from a workpiece to create a desired shape or form. This is done using a variety of tools such as lathes, milling machines, and drill presses. The material is cut away in small increments until the desired shape is achieved. Fabrication is an additive manufacturing process that involves joining two or more pieces of material together to create a desired shape or form. This is done using a variety of tools such as welding, riveting, and soldering. The pieces are joined together in a specific order and with a specific technique to create the desired shape. Both machining and fabrication are used in a variety of industries to create parts and components for a variety of applications.

What is turning machining process?

Turning machining process is a type of subtractive manufacturing process used to create cylindrical parts by removing material from a rotating workpiece. It is a type of machining operation that uses a single-point cutting tool to remove material from the surface of a rotating workpiece. The cutting tool is usually held in a tool holder and is advanced along the surface of the workpiece in a linear or helical path. The cutting tool can be fed into the workpiece in a variety of ways, including manual feed, automatic feed, and programmed feed. The cutting tool can be moved in a variety of directions, including radial, axial, and helical. The cutting tool can also be moved in a variety of speeds, including high speed, low speed, and variable speed.

The turning process is used to create a variety of parts, including shafts, pins, bushings, and other cylindrical parts. The turning process can also be used to create complex shapes, such as splines, threads, and grooves.

What is mechanical machining?

Mechanical machining is a manufacturing process that involves the use of tools to remove material from a workpiece in order to shape or finish it into a desired shape or form. It is a subtractive process, meaning that material is removed from the workpiece in order to achieve the desired shape or form. Mechanical machining is one of the oldest and most widely used manufacturing processes, and is used to create parts for a wide variety of industries, including automotive, aerospace, medical, and consumer products.

The process of mechanical machining involves the use of cutting tools, such as drills, milling cutters, and lathes, to remove material from the workpiece. The cutting tools are typically made of high-speed steel or carbide, and are designed to cut through the material at a specific rate. The cutting tools are usually powered by a motor, and the speed and direction of the cutting tool can be adjusted to achieve the desired shape or form.