When it comes to CNC (Computer Numerically Controlled) machining parts, there are many factors to consider when determining the optimal parameters for the production process. These factors include the material of the part, the speed and feed rate, the type of tooling used, and the cutting conditions. It is important to consider all of these factors when determining the best parameters to ensure the part is accurately and efficiently produced. This article will explain in detail the factors that should be taken into consideration when determining the optimal machining parameters for CNC machining parts.

An Overview of CNC Machining and the Factors to Consider When Choosing Machining Parameters

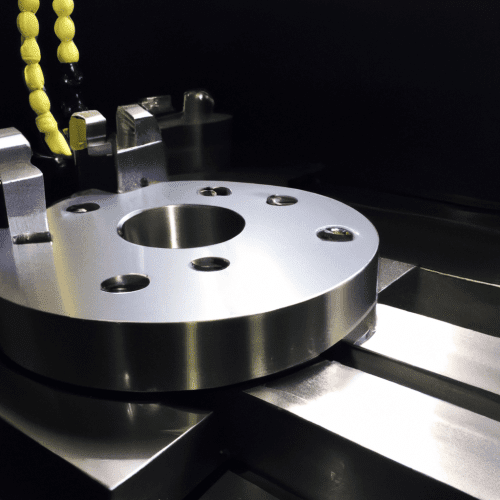

CNC Machining is a process used to create precision components with high levels of accuracy and repeatability. It is used to produce parts from a wide variety of materials including metals, plastics, composites, and ceramics. It can be used for both prototyping and production-level parts. When selecting machining parameters for a CNC machining project, there are several factors to consider. First, the material being machined must be taken into account. Different materials have different properties and require different cutting speeds, tooling, and feeds. The hardness, strength, and ductility of the material will determine the type of tooling required and the appropriate cutting speed. Second, the size of the part and the complexity of its shape must be considered. If the part is small and simple, then high cutting speeds and aggressive tooling may be used to quickly manufacture the part.

If the part is large and complex, then slower cutting speeds and less aggressive tooling may be required in order to achieve a good finish. Third, the desired finish must be taken into account. If a smooth finish is desired, then slower cutting speeds and less aggressive tooling will be required. If a rougher finish is acceptable, then faster cutting speeds and more aggressive tooling may be used. Finally, the accuracy of the part must be considered. If a high degree of accuracy is required, then slower cutting speeds and more conservative tooling should be used. If less accuracy is acceptable, then faster cutting speeds and more aggressive tooling may be used. In summary, CNC machining is a highly precise process used to create parts with high levels of accuracy and repeatability. When selecting machining parameters, the material, size, complexity, desired finish, and accuracy should all be taken into account. By considering these factors, the best machining parameters can be determined to produce the desired part.

How to Calculate the Optimal Cutting Parameters for CNC Machining Parts

CNC (Computer Numerical Control) machining is a process used to fabricate complex parts with precise measurements and intricate geometries. To ensure accuracy and high-quality results, it is important to select the optimal cutting parameters for the CNC machining process. To calculate the optimal cutting parameters, it is necessary to consider the material properties, the type of tooling used, the desired surface finish, and the desired cutting speed. The material properties of the part should be carefully evaluated to determine the optimal cutting parameters. The type of material, its hardness, and its strength can all affect the cutting parameters. For example, harder materials require higher spindle speeds and shallower cutting depths.

Once the material properties are identified, the type of tooling used must be evaluated. Cutting tools should be chosen based on the material properties and the type of surface finish desired. The surface finish of the part is also an important factor to consider when calculating the optimal cutting parameters. The surface finish of the part can be specified by the Ra (roughness average) value, which is the average roughness of the surface. The Ra value should be chosen based on the desired appearance and functionality of the part. Generally, lower Ra values result in smoother surfaces and improved functionality. In addition to the material properties and desired surface finish, the cutting speed should also be considered when determining the optimal cutting parameters. Cutting speed is the rate at which the cutting tool moves across the material being machined. Higher cutting speeds result in faster machining times, but can also cause excessive tool wear and reduced surface finish quality. It is important to select a cutting speed that is appropriate for the material and the desired surface finish.

By carefully evaluating the material properties, the type of tooling, the desired surface finish, and the desired cutting speed, it is possible to calculate the optimal cutting parameters for CNC machining. These parameters can then be used to ensure accuracy and high-quality results for complex parts.

The Benefits of Using CNC Machining for Precision Parts

CNC (Computer Numerical Control) machining is a manufacturing technique that uses a computer program to control the movements of a machine tool. It is often used for the production of precision parts for a variety of industries. CNC machining is capable of producing accurate and repeatable parts with very tight tolerances, making it a popular choice for many applications. The primary benefit of using CNC machining for precision parts is its accuracy and repeatability. CNC machining can produce parts that are extremely precise, as it is guided by the computer program that controls the machine. This means that the same part can be reproduced precisely, and with a high degree of accuracy. This level of precision ensures that parts can be produced that meet very strict specifications.

In addition to precision, CNC machining also offers high levels of repeatability. The computer program that controls the machine can be programmed to repeat the same operation multiple times, ensuring that all parts produced are identical. This can be extremely beneficial for producing parts in high volumes since the same part can be produced with consistent accuracy and quality. CNC machining also provides many other benefits. It can be used to produce parts with complex shapes and detailed geometries, such as those found in medical devices or aerospace components. The computer program that controls the machine can also be programmed to produce parts with specific surface finishes, such as those needed for specific applications. CNC machining is also a very cost-effective method of production. It requires minimal setup time, as the machine is already programmed to produce the part. This means that the same part can be produced multiple times without having to reset the machine, saving both time and money. Overall, CNC machining is an excellent choice for producing precision parts. It offers high levels of accuracy, repeatability, and cost-effectiveness, making it a popular choice for many industries. With its ability to produce complex shapes and detailed geometries, CNC machining is a great choice for precision parts production.

Exploring the Different Types of CNC Machining and Their Variables

CNC (Computer Numerical Control) machining is an automated manufacturing process that uses programmed computer software to control machine tools. This technology has revolutionized the manufacturing industry, allowing for increased accuracy, speed, and precision in the production of parts and components. CNC machining can be used to produce a wide variety of parts and components, from simple metal parts to complex plastic components. CNC machining is divided into several different types, each with its own unique characteristics and variables. The most widely used type of CNC machining is milling, which uses a rotating cutting tool to shape and finish a workpiece. Milling can be done on a variety of materials, including aluminum, brass, steel, plastic, and wood, and can be used to create complex parts and components.

Other types of CNC machining include turning, drilling, and grinding. Each type of CNC machining has its own set of variables, such as cutting speed, feed rate, and tooling. When selecting the type of CNC machining to use, there are a few key factors to consider. First, the material to be machined should be taken into account. Different materials require different tooling and cutting speeds, so it’s important to choose a machining type that is compatible with the material. Additionally, the complexity of the part being produced should be taken into consideration when selecting the type of CNC machining to use. Some machining types are better suited for complex geometries than others. The speed and accuracy of the machining process is also important when selecting the type of CNC machining to use. Generally, the faster the machining process, the more accurate the finished product will be. The type of cutting tool used can also affect the speed and accuracy of the machining process. For example, some tools are designed to cut faster than others, while some tools are designed to provide a higher level of accuracy. It’s important to choose the type of cutting tool that is best suited to the job at hand. Finally, the type of control system used for CNC machining should also be taken into consideration.

Different types of control systems can provide different levels of accuracy and speed, so it’s important to choose the system that is best suited to the job at hand. CNC machining is a powerful and versatile manufacturing process that can be used to create a wide range of parts and components. By understanding the different types of CNC machining and their variables, businesses can select the right type of machining for their needs and ensure the highest level of accuracy and speed.

An Overview of Tool Paths and Their Impact on Machining Parameters

Tool path is an important machining parameter that has a significant impact on the quality, accuracy, and cost of the parts machined. Tool path is the path taken by the cutting tool when it cuts the material. It is the path that the cutting tool is moved along the workpiece to make the desired shape. Tool path is determined by the type of machining operation, the geometry of the part, the cutting tool used, and the type of material being machined. Tool path can be determined manually by a skilled operator or it can be determined through computer-aided design (CAD) and computer-aided manufacturing (CAM) programs. The tool path determines the amount of material that is removed, how quickly it is removed, and the type of surface finish that is obtained on the part. It also affects the cutting forces on the cutting tool and the cutting tool’s life.

Tool path can be optimized to reduce cutting time and improve the overall quality of the machined part. The most common types of tool paths are linear, circular, and contour tool paths. Linear tool paths are used for straight-line cutting operations such as drilling, reaming, and tapping. Circular tool paths are used for turning operations and contour tool paths are used for milling operations. The choice of tool path can have a significant impact on the machining parameters such as cutting speed, feed rate, depth of cut, and cutting tool life. For example, a circular tool path will require a slower cutting speed than a linear tool path in order to produce a smooth surface finish. Similarly, a contour tool path requires a slower feed rate than a linear tool path in order to reduce cutting forces and improve tool life. In conclusion, tool path is an important machining parameter that has a significant impact on the quality, accuracy, and cost of the parts machined. It is important to select the appropriate tool path for a given machining operation in order to ensure that the desired results are achieved.

How to Optimize CNC Machining Parameters for Maximum Efficiency

CNC machining is a process that uses computer-controlled machines to shape materials like metal, plastic, and wood. This process offers a number of advantages, including speed, accuracy, repeatability, and cost savings. However, to ensure maximum efficiency of CNC machining, it is important to optimize the machining parameters. Here are some tips to help you do just that.

1. Choose the Proper Tool: The first step in optimizing machining parameters is to select the proper tool. This includes the correct cutting tool, as well as the right tool geometry for the material being machined. The tool should also be properly sharpened and balanced to ensure optimal performance.

2. Establish Feeds and Speeds: Once the right tool is chosen, it’s important to set the correct feeds and speeds for the machining process. This includes the cutting speed, feed rate, and the depth of cut. If these parameters are not set correctly, it can lead to poor quality, inaccurate parts, and increased wear on the cutting tool.

3. Monitor Your Process: Once the parameters are set, it’s important to monitor the process closely. This includes keeping an eye on the cutting tool as well as the workpiece to ensure the machining process is running smoothly. Any abnormalities should be addressed immediately to ensure the maximum efficiency of the machining process.

4. Use the Right Coolant: To ensure maximum efficiency of CNC machining, it’s important to use the right coolant. Different materials require different types of coolant, and using the wrong type can lead to poor quality parts and increased wear on the cutting tool. By following these tips, you can ensure that your CNC machining process is optimized for maximum efficiency. Using the right tool, setting the correct parameters, monitoring the process, and using the right coolant can all help to ensure that your parts are machined accurately and quickly.

Exploring the Impact of Material Properties on Machining Parameters

The machining process is a crucial part of manufacturing, as it is used to shape materials to produce parts and components. As such, it is important to understand how material properties can influence machining parameters. Material properties can have a direct effect on the machining process, as they determine the type of tooling and cutting parameters required to achieve a given result. For example, the hardness of the material can have a direct influence on the cutting speed used, as harder materials require higher cutting speeds to prevent tool wear. Similarly, the strength of the material can affect the depth of cut, as a deeper cut may be required in order to cut through stronger materials. In addition, material properties can also affect the surface finish of the machined parts. For instance, softer materials may be more prone to tool chatter, which can create a rougher surface finish. Conversely, harder materials may require a higher feed rate to achieve the desired surface finish.

Finally, material properties can also influence the cutting forces experienced during the machining process. For instance, harder materials typically generate higher cutting forces than softer materials, as they require a greater amount of force to remove the material. In conclusion, it is important to consider the material properties when selecting machining parameters, as they can have a significant impact on the results of the machining process. By understanding the relationship between material properties and machining parameters, it is possible to achieve the desired results more efficiently and with higher quality.

In conclusion, when determining the optimal machining parameters for CNC machining parts, it is important to consider the material of the parts, the intended application, the cutting tool being used, the cutting speed, the feed rate, the depth of cut, and the coolant being used. By taking all of these factors into account, it is possible to achieve optimal results from CNC machining.