CNC Training Centres are educational institutions that provide training and instruction on the use of Computer Numerical Control (CNC) machines. CNC machines are computer-controlled tools, such as lathes, mills, routers, and grinders, used to create precision parts. CNC Training Centres typically teach students how to use CNC machinery to create parts for a variety of industries, such as automotive, aerospace, electronics, and medical. They also provide instruction on design, programming, and safety protocols for CNC machines. With CNC Training Centers, students can further their knowledge and develop the skills necessary to become a skilled CNC operator.

Overview of CNC Training Centres: What They Are and What They Offer

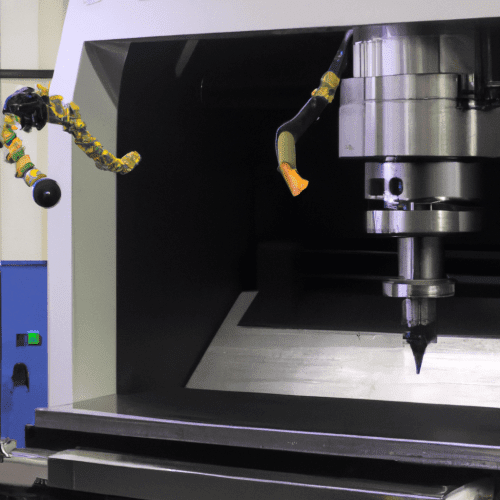

CNC (Computer Numerical Control) training centres are educational institutes that specialize in teaching students how to use CNC machines, tools, and software. CNC machines are used in a variety of industries, including aerospace, automotive, and medical device manufacturing. CNC training centres provide students with the knowledge and skills necessary to become proficient in the use of CNC machines, tools, and software. CNC training centres typically offer courses in CNC programming, machine operations, and machine maintenance. CNC programming courses teach students the basics of programming CNC machines to perform specific tasks. Students learn how to write code to control the machines and create parts, as well as how to troubleshoot and debug programs.

Machine operation courses teach students how to safely operate CNC machines, including proper set up and operation of the machine. Machine maintenance courses provide students with the skills and knowledge needed to properly maintain CNC machines, including how to identify and correct machine faults. CNC training centres also provide students with hands-on experience using CNC machines in a laboratory setting. During their time in the lab, students learn how to safely and effectively use the machines, tools, and software. They also get the opportunity to work on real-world projects and become familiar with the different types of CNC machines and software. CNC training centres provide students with the skills and knowledge needed to become successful in the use of CNC machines, tools, and software. By learning these skills, students can pursue careers in a variety of industries and become proficient in the use of CNC machines.

What to Consider When Choosing a CNC Training Centre

Choosing a CNC training centre is an important decision that should not be taken lightly. It is essential to choose a centre that will provide the necessary knowledge and skills to succeed in the field. Here are a few things to consider when selecting a CNC training centre.

1. Accreditation: Ensure that the CNC training centre is accredited by a recognised body, such as the National Institute for Metalworking Skills (NIMS). Accreditation ensures that the centre follows best practices and provides quality training.

2. Course Material: Make sure the CNC training centre provides comprehensive course material. This should include theory, practical instruction and hands-on experience. The material should be up-to-date and relevant to the current industry standards.

3. Instructors: The instructors should be qualified and well-versed in the subject matter. They should also be able to provide tips and advice to help you succeed in the field.

4. Facilities: Ensure that the CNC training centre has access to the necessary equipment and facilities. This should include the latest CNC machines, software and other tools.

5. Support: The centre should provide ongoing support and assistance after the course is completed. This could include job placement, career guidance and other resources. When choosing a CNC training centre, it is important to do your research and find the right one for you. Consider the accreditation, course material, instructors, facilities and support offered before making a final decision.

Gaining Hands-On Experience in CNC Manufacturing Through CNC Training Centres

Gaining hands-on experience in CNC manufacturing can be a valuable asset for any aspiring manufacturing professional. CNC training centers provide a valuable opportunity to gain this experience, as they offer a range of courses that provide students with the necessary skills to become proficient in CNC machining. CNC training centers offer courses tailored to a variety of skill levels. From beginner courses that cover the basics of CNC programming, to advanced courses that focus on complex machining processes and CAD/CAM software, there is a course that can suit the needs of any aspiring CNC machinist. Through these courses, students will learn the principles of CNC programming, as well as the different types of CNC machines and how to use them.

In addition, they will be able to gain experience with the necessary software and techniques used in CNC manufacturing. In addition to the classroom instruction, CNC training centers also provide students with the opportunity to gain hands-on experience through virtual and physical simulations. Through these simulations, students can become familiar with the processes used in CNC machining, as well as the necessary safety protocols. This allows them to gain an understanding of what it takes to operate a CNC machine, as well as the various components and tools used in the process. Finally, CNC training centers offer the opportunity for students to gain experience in the workplace by participating in internships and apprenticeships. These programs provide students with the opportunity to gain real-world experience in CNC manufacturing, as well as gaining valuable knowledge and experience from experienced professionals. Gaining hands-on experience in CNC manufacturing is an invaluable asset for any aspiring manufacturing professional.

Through CNC training centers, students have the opportunity to gain the necessary skills and experience needed to become proficient in CNC machining. With the right instruction and experience, CNC machinists can become a valuable asset to any manufacturing organization.

Tips for Getting the Most Out of Your CNC Training Centre

1. Make sure that you are familiar with the basic concepts and principles of CNC operations before beginning your training. This will ensure that you are able to keep up with the pace of the class and maximize the benefit of the training.

2. Come prepared with questions. It is important to ask questions during the course so that you can get a better understanding of the material. This will help you to gain insights that you may not have had without asking questions.

3. Make sure to take notes during the class. Writing down your thoughts and notes during the class can help you to remember key concepts and remember the material better.

4. Utilize the resources provided by the CNC training centre. These resources may include textbooks, videos, and software demos. Make sure to take advantage of these resources to ensure that you are getting the most out of the training.

5. Participate in hands-on activities. Many CNC training centres offer hands-on activities that allow you to apply the concepts that you are learning. It is important to take advantage of these activities to gain experience in working with CNC machines.

6. Practice the concepts that you have learnt. Practicing with CNC machines will help you to gain confidence in the material and will help you to become more comfortable with operating a CNC machine.

7. Make sure to attend all classes and stay up to date with the material. Attending the classes and staying on top of the material will ensure that you are able to get the most out of your CNC training.

Exploring the Benefits of CNC Training Centres for Businesses

The use of CNC (Computer Numerical Control) machines is becoming increasingly common in the world of manufacturing and engineering. As businesses strive to remain competitive, the importance of CNC machines has become even more apparent. This is why it is important for businesses to understand the benefits of CNC training centres and how they can be used to gain a competitive edge. A CNC training centre provides a range of benefits to businesses. Firstly, it enables them to make use of the latest technology in a cost-effective manner. By providing training at a CNC training centre, businesses can ensure that their staff are up to date with all the newest technology and techniques. This allows them to remain competitive in their respective fields and gain a competitive edge over their competitors. The training provided by a CNC training centre also helps to improve the safety standards within a business.

As CNC machines are becoming increasingly complex, it is essential that staff are trained to use them safely and efficiently. By providing employees with the skills and knowledge required to use CNC machines, businesses can ensure that they are operating safely and effectively. CNC training centres also offer businesses the opportunity to save money. As CNC technology is constantly changing, businesses can benefit from the cost savings that come with investing in a CNC training centre. By providing staff with the necessary skills and knowledge to use CNC machines, businesses can save money on the cost of purchasing and maintaining the machines. Finally, CNC training centres can help businesses to stay ahead of the competition. By investing in CNC training, businesses can ensure that their employees are up to date on the latest technology and techniques. This ensures that they are able to remain competitive in their respective fields and have an advantage over their competitors. In conclusion, CNC training centres offer a range of benefits to businesses.

By providing staff with the skills and knowledge necessary to use CNC machines, businesses can ensure that they are operating safely and effectively. Additionally, businesses can save money on the cost of purchasing and maintaining the machines, while remaining competitive in their respective fields. Investing in a CNC training centre is a worthwhile investment for any business.

How CNC Training Centres Can Help You Advance Your Career

CNC (computer numerical control) training centres offer a range of courses that can help individuals advance their career. These courses focus on teaching students the latest techniques and technologies in CNC machining, as well as the fundamentals of the industry. CNC training centres provide an opportunity to learn the skills required to become a proficient CNC machinist. Through these courses, individuals can gain a strong understanding of CNC operations and the various machine tools used in the industry. Training centres also provide hands-on instruction in the use of CNC machinery, allowing students to gain practical experience. CNC training centres also offer a range of specialist courses that can help individuals advance their career. For example, many centres offer courses that focus on the design and production of CNC parts. These courses provide students with the skills necessary to create high-quality components more efficiently.

Furthermore, some CNC training centres also offer courses on programming and software. These courses teach students how to write programs for CNC machines and how to use software to control operations. This knowledge can be invaluable in the modern workplace, where computer-controlled machines are becoming increasingly commonplace. Overall, CNC training centres provide an invaluable opportunity for individuals to learn the skills necessary to advance their career. By taking courses offered by these centres, individuals can gain a comprehensive understanding of CNC operations that can be beneficial in many industries.

Exploring the Latest Technologies Used in CNC Training Centres

CNC (Computer Numerical Control) training centres are quickly becoming the go-to option for those who want to learn the technical skills associated with this field. As the demand for CNC technicians rises, the technology used to teach the craft is also advancing. CNC training centres are now using the latest technologies to ensure that students are receiving the highest quality education. The most common technologies used in CNC training are CAD (Computer Aided Design) and CAM (Computer Aided Manufacturing). CAD is used to create 3D models that can be used to create CNC programs. CAM is then used to convert these models into instructions that are sent to the CNC machine. This allows for precise and accurate machining of materials.

Many CNC training centres are investing in virtual reality (VR) technology. This technology allows instructors to create a realistic environment in which students can practice their skills. Students can learn how to operate CNC equipment in a simulated environment without the fear of making costly mistakes. CNC trainers are also using 3D printing to help students understand the complexities of CNC programming. 3D printing allows students to create physical prototypes of their designs. This gives students the opportunity to test their designs without using expensive CNC machines. Robotics is also being used in CNC training centres. Robotics offer a more hands-on approach to learning CNC programming. Students can use robotic arms and legs to learn how to program CNC machines and create precise movements. Finally, CNC trainers are utilizing the latest software to teach students the fundamentals of CNC programming. This software allows students to learn the basics of CNC programming in an interactive and user-friendly environment.

Furthermore, this software can be used to create complex CNC programs with ease. These are just a few of the latest technologies being used in CNC training centres. These technologies are helping to create a more effective and efficient learning environment for CNC students. As the demand for CNC technicians increases, we can expect to see even more advanced technologies being used in CNC training centres.

In conclusion, CNC training centres provide an invaluable service to those looking to become skilled in CNC machining and manufacturing. With the help of experienced instructors and state-of-the-art equipment, students can gain the necessary knowledge and skills to succeed in the CNC industry. This makes CNC training centres a great resource for anyone looking to break into the field.