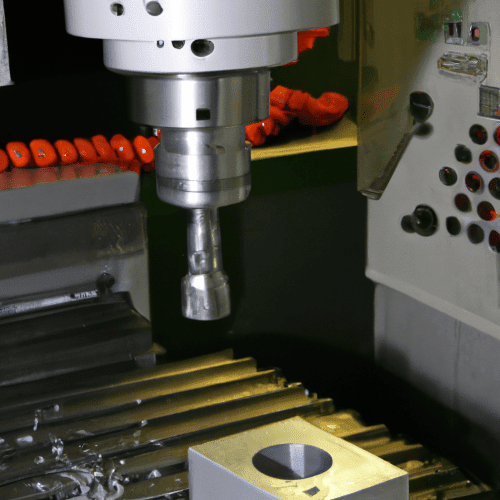

A phase milling machine is a type of milling machine that uses a rotating cutter to remove material from a workpiece. It is typically used to create precise shapes and features on a workpiece, such as slots, grooves, and contours. The cutter is mounted on a spindle that is driven by a motor, and the workpiece is mounted on a table that can be adjusted to different angles. The cutter is moved along the workpiece in a series of passes, each pass removing a small amount of material. The depth of the cut and the speed of the cutter can be adjusted to create the desired shape and size. The phase milling machine is used in a variety of industries, including automotive, aerospace, and medical. It is also used in the production of precision parts, such as gears, bearings, and other components.

What are the two types of milling?

Milling is a machining process that uses a rotating cutting tool to shape and form materials such as metal, wood, and plastic. There are two main types of milling: peripheral milling and face milling.

Peripheral milling is a type of milling that uses a rotating cutting tool to cut along the circumference of a workpiece. This type of milling is used to create slots, grooves, and other features on the outside of a workpiece. It is also used to create contours on the outside of a workpiece.

Face milling is a type of milling that uses a rotating cutting tool to cut flat surfaces into a workpiece. This type of milling is used to create flat surfaces, such as those found on the top and bottom of a workpiece. It is also used to create angled surfaces, such as those found on the sides of a workpiece. Face milling is often used to create a smooth finish on a workpiece.

What does a milling machine do?

A milling machine is a machine tool used for the shaping of metal and other solid materials. It typically uses a rotating cutting tool to shape and form the material into a variety of different shapes and sizes. Milling machines can be used to perform a variety of operations, including drilling, boring, reaming, tapping, and countersinking. They can also be used to create complex shapes and contours, as well as to cut slots and keyways. Milling machines are used in a variety of industries, including automotive, aerospace, medical, and industrial manufacturing. They are also used in the production of precision parts, such as gears, bearings, and other components. Milling machines are available in both manual and CNC (computer numerical control) versions, and can be used to produce a wide range of products.

How do you run a 3 phase milling machine on single phase?

Running a 3 phase milling machine on single phase power is possible, but it requires the use of a phase converter. A phase converter is an electrical device that converts single phase power into three phase power. This allows the 3 phase milling machine to run on single phase power.

Phase converters come in two types: rotary and static. Rotary phase converters use a motor to generate the third phase, while static phase converters use capacitors and other components to generate the third phase. Rotary phase converters are more expensive than static phase converters, but they are more efficient and can handle larger loads.

When selecting a phase converter, it is important to consider the size of the milling machine and the amount of power it requires. The phase converter should be able to provide enough power to run the milling machine without overloading the converter. It is also important to make sure the phase converter is compatible with the milling machine.

Once the phase converter is installed, it is important to follow the manufacturer’s instructions for proper operation.

What are the main parts of milling machine?

A milling machine is a machine tool used for the shaping of metal and other solid materials. It typically consists of a base, a rotating cutting tool called a milling cutter, and a table that moves in three directions to adjust the cutting depth and angle. The base of the milling machine is made up of a bed, which is a flat, horizontal surface that holds the workpiece in place. The bed is usually made of cast iron and is connected to the machine’s frame. The milling cutter is a rotating cutting tool that is used to shape the workpiece. It is usually made of high-speed steel and is mounted on an arbor, which is a shaft that is connected to the machine’s spindle. The table is a flat, horizontal surface that moves in three directions to adjust the cutting depth and angle. It is usually made of cast iron and is connected to the machine’s frame. The table can be adjusted manually or with a power feed. The spindle is the rotating shaft that holds the milling cutter in place and is connected to the motor.

How are milling machines classified?

Milling machines are classified according to their orientation, the cutting tool they use, the number of axes they have, and the type of control they use.

Orientation refers to the direction in which the cutting tool is positioned relative to the workpiece. The two main types of milling machines are horizontal and vertical. Horizontal milling machines have the cutting tool mounted on a horizontal spindle, while vertical milling machines have the cutting tool mounted on a vertical spindle.

The cutting tool used by a milling machine can be either a rotating cutter or a stationary cutter. Rotating cutters are typically used for general-purpose milling operations, while stationary cutters are used for more specialized operations.

The number of axes refers to the number of directions in which the cutting tool can move. Milling machines typically have three axes: the X-axis, the Y-axis, and the Z-axis.

What is triplex milling machine?

A triplex milling machine is a type of machine tool used for milling operations that involve the use of multiple cutting tools. It is a specialized type of milling machine that is designed to perform multiple operations in a single setup. The triplex milling machine is capable of performing three operations simultaneously, such as drilling, boring, and milling. It is also capable of performing multiple operations in a single pass, such as drilling, boring, and milling.

The triplex milling machine is a versatile machine tool that can be used for a variety of operations. It is capable of performing operations such as drilling, boring, reaming, tapping, and threading. It is also capable of performing operations such as milling, grinding, and polishing. The triplex milling machine is capable of performing operations on a variety of materials, including metals, plastics, and composites.