The top hobby milling machines for your workshop include the Proxxon MF 70, Grizzly G8689, Sherline 5400, and Taig Micro Mill II. These compact and versatile machines offer precision and reliability for hobbyists and small-scale manufacturers. The Proxxon MF 70 stands out for its high-speed spindle and fine adjustment capabilities, making it ideal for detailed work. Grizzly’s G8689 provides a larger work envelope and more robust construction, suitable for heavier-duty tasks.

The Sherline 5400 is known for its expandability and wide range of accessories, allowing users to tackle diverse projects. The Taig Micro Mill II excels in accuracy and is favored by model makers and jewelers. Each of these machines offers unique features to cater to different hobbyist needs, from intricate modelmaking to small parts fabrication, ensuring that DIY enthusiasts and small workshop owners can find a milling solution that fits their specific requirements and space constraints.

Best Budget Milling Machine: Proxxon Micro Milling Machine

When it comes to finding the best budget milling machine for your hobbyist needs, the Proxxon Micro Milling Machine is an excellent choice. This compact and lightweight machine offers powerful performance and precision without breaking the bank.

Despite its affordability, the Proxxon Micro Milling Machine is built to deliver exceptional results. Whether you’re shaping, cutting, or drilling, this machine provides the accuracy and versatility you need for your projects.

With its compact design, this milling machine is perfect for small workshops or home use. It doesn’t take up much space while still offering the functionality and performance you would expect from a larger machine.

One of the standout features of the Proxxon Micro Milling Machine is its ease of use. It is designed with hobbyists in mind, making it accessible for beginners and enthusiasts alike. You don’t need to be a professional machinist to operate this machine effectively.

This budget-friendly milling machine also offers excellent value for money. You get a high-quality and reliable tool that meets your hobbyist needs while staying within your budget.

Key Features:

- Compact and lightweight design

- Powerful performance and precision

- Versatile for various tasks

- Easy to use, suitable for beginners

- Affordable and great value for money

| Specifications | Proxxon Micro Milling Machine |

|---|---|

| Dimensions | 12.6 x 10.6 x 17.3 inches |

| Weight | 37.5 pounds |

| Motor Power | 200 watts |

| Speed | 500 – 5,000 RPM |

| Max. Milling Width | 5.3 inches |

| Max. Milling Depth | 0.08 inches |

Best Milling Machine for Home Use: Precise Mini Milling and Drilling Machine

If you’re a hobbyist looking to set up a milling machine in your home workshop, the Precise Mini Milling and Drilling Machine is the perfect choice. This compact yet powerful machine is designed to handle a variety of milling and drilling tasks with precision and accuracy. It offers the convenience and reliability you need for home use.

With its compact size, the Precise Mini Milling and Drilling Machine is suitable for smaller workshop spaces. It won’t take up too much room, allowing you to maximize your workspace. Despite its small size, this machine packs a punch with its powerful motor, delivering the performance you need to accomplish your milling projects.

Features of the Precise Mini Milling and Drilling Machine:

- Precision and accuracy: This machine ensures precise and accurate milling and drilling results, allowing you to achieve the desired outcomes for your projects.

- Compact size: The compact design makes it suitable for home workshops with limited space. You can easily fit it into your existing setup without sacrificing workspace.

- Powerful motor: Despite its small size, this machine is equipped with a powerful motor that provides reliable performance for a wide range of milling and drilling tasks.

- Versatile capabilities: The Precise Mini Milling and Drilling Machine can handle various materials and applications, giving you the flexibility to work on different projects.

Whether you’re a beginner or an experienced hobbyist, the Precise Mini Milling and Drilling Machine is a top choice for home use. Its compact size, powerful motor, and precise results make it the best milling machine for your home workshop.

Best Milling Machine for a Small Shop: Sharp Industries Premium Vertical Knee Mill

If you have a small workshop, the Sharp Industries Premium Vertical Knee Mill is the perfect choice for you. This milling machine offers a combination of functionality and space-saving design. With its 3-axis capability and powerful motor, it can handle various milling operations. The Sharp Industries Premium Vertical Knee Mill is a durable and efficient option for small shop owners.

Key Features of the Sharp Industries Premium Vertical Knee Mill

- 3-axis capability for versatile milling operations

- Powerful motor for efficient performance

- Space-saving design ideal for small workshops

- Durable construction for long-lasting use

| Feature | Description |

|---|---|

| 3-axis capability | Allows for precise milling operations in multiple directions |

| Powerful motor | Enables efficient cutting and shaping of various materials |

| Space-saving design | Perfect for small shops with limited workspace |

| Durable construction | Ensures long-lasting performance and reliability |

The Sharp Industries Premium Vertical Knee Mill combines durability, efficiency, and functionality, making it the best milling machine for small shop owners. With its compact design and powerful features, this machine is capable of handling a wide range of milling tasks. Whether you need to cut, shape, or drill, this milling machine delivers precise results every time.

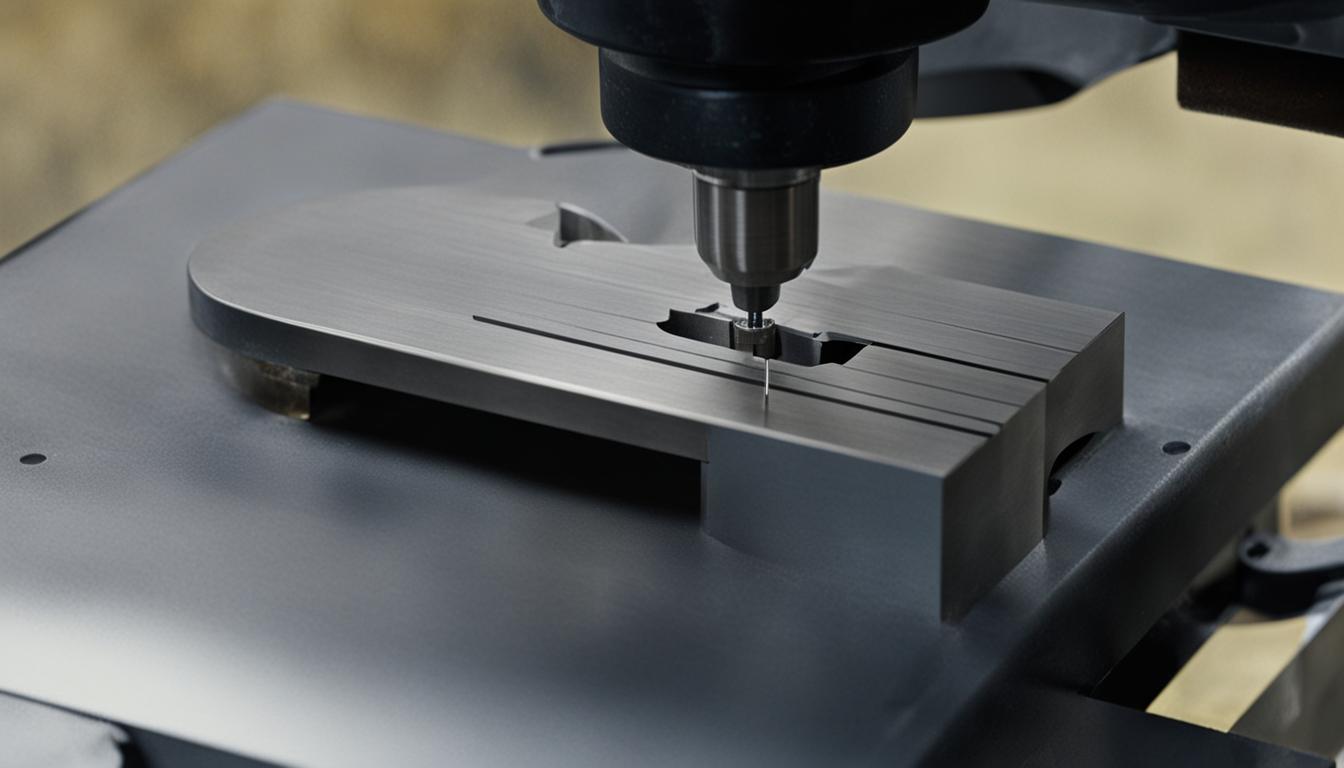

Best CNC Milling Machine: JET CNC Vertical Turret Milling Machine

For hobbyists looking for advanced features and precise milling capabilities, the JET CNC Vertical Turret Milling Machine is the best choice. This machine is computer-controlled and offers high-speed, high-precision milling operations. With its powerful motor and variable speed spindle, it is ideal for industries that require automation and precision. The JET CNC Vertical Turret Milling Machine is a top-of-the-line option for those who want the best CNC capabilities.

Here are some key features of the JET CNC Vertical Turret Milling Machine:

- Computer-controlled operations for precise milling

- High-speed and high-precision capabilities

- Powerful motor for efficient performance

- Variable speed spindle for versatile milling tasks

With its cutting-edge technology and superior performance, the JET CNC Vertical Turret Milling Machine is a favorite among hobbyists who demand the best CNC milling machine. Its advanced features and precision make it a valuable tool for industries that prioritize automation and accuracy.

Upgrade your milling capabilities with the JET CNC Vertical Turret Milling Machine and experience the power of advanced CNC technology.

Best Combination Vertical/Horizontal Milling Machine: Kent Combination Horizontal and Vertical Spindle Milling Machine

The Kent Combination Horizontal and Vertical Spindle Milling Machine is a versatile tool that offers both vertical and horizontal milling capabilities. With its powerful 5 HP motor and tilting table, it provides flexibility for a wide range of milling operations. This machine is perfect for small to medium-sized workshops that require a combination of vertical and horizontal milling capabilities.

Whether you need to perform precise vertical milling tasks or horizontal milling operations, the Kent Combination Milling Machine has got you covered. Its robust construction and reliable performance make it a top choice for hobbyists and professionals alike.

Key Features of the Kent Combination Horizontal and Vertical Spindle Milling Machine:

- Powerful 5 HP motor for efficient operation

- Tilting table for versatile milling angles

- Combines vertical and horizontal spindle for increased capabilities

- Compact design for small to medium-sized workshops

- Easy-to-use controls for precise milling

Whether you’re working on small-scale projects or tackling more complex milling tasks, the Kent Combination Horizontal and Vertical Spindle Milling Machine is the best choice for combining vertical and horizontal milling operations in one reliable and efficient machine.

Best Combination Gear Drive Milling & Drill Machine: Gear Drive Mill/Drill Machine (OT7045FG)

The Gear Drive Mill/Drill Machine (OT7045FG) is an exceptional tool that combines the functionalities of both milling and drilling. With its gear drive system and powerful 1.5 HP motor, it can efficiently handle high-speed drilling and milling operations.

Equipped with a digital readout system, this machine ensures precise and accurate results, allowing you to achieve your desired measurements with ease. Additionally, the automatic lubrication feature enhances its performance and simplifies maintenance, saving you valuable time and effort.

Whether you’re a hobbyist or a professional, the Gear Drive Mill/Drill Machine (OT7045FG) offers an optimal combination of power, precision, and convenience. It is suitable for a variety of applications and is an excellent addition to any workshop.

Klutch Mini Milling Machine

The Klutch Mini Milling Machine is a versatile tool that is perfect for hobbyists. With its compact size and powerful motor, it can handle a variety of milling tasks. This machine offers easy setup and precise control, making it an excellent choice for hobbyists who want reliability and functionality.

Key Features:

- Compact size for easy storage and portability

- Powerful motor for efficient milling

- Easy setup and user-friendly controls

- Precise milling capabilities for accurate results

Whether you’re a novice hobbyist or an experienced DIY enthusiast, the Klutch Mini Milling Machine is designed to meet your needs. Its compact size allows you to work in small spaces while still delivering high performance. From shaping materials to drilling precise holes, this machine can handle a wide range of tasks with ease.

The Klutch Mini Milling Machine is built to last, with a durable construction that ensures longevity and reliability. Its precise control features allow you to achieve the desired results with accuracy and precision, making it an essential tool for any hobbyist’s workshop.

Get ready to take your hobbyist projects to the next level with the Klutch Mini Milling Machine. Whether you’re working on woodworking, metalworking, or other DIY projects, this machine will help you achieve professional-level results.

| Pros | Cons |

|---|---|

| Compact size for easy storage and portability | May not be suitable for heavy-duty industrial use |

| Powerful motor for efficient milling | Limited milling capacity compared to larger machines |

| Easy setup and user-friendly controls | May require additional accessories for certain milling tasks |

| Precise milling capabilities for accurate results | May not be suitable for large-scale projects |

WEN 33013 Benchtop Milling Machine

The WEN 33013 Benchtop Milling Machine is an excellent choice for hobbyists in search of a reliable and user-friendly milling machine. With its compact design and variable speed control, this machine is perfect for small-scale projects. Whether you’re working on woodworking, metalworking, or other precision tasks, the WEN 33013 Benchtop Milling Machine offers versatility and precision to help you achieve the desired results with ease.

Key features of the WEN 33013 Benchtop Milling Machine include:

- Powerful motor

- Variable speed control

- Compact design

- Easy setup and operation

- Precision and accuracy

With its powerful motor, the WEN 33013 Benchtop Milling Machine can handle a variety of materials and deliver consistent and precise results. The variable speed control allows you to adjust the milling speed according to the task at hand, providing you with complete control over the milling process.

The compact design of this machine is ideal for hobbyists with limited workshop space. Its small footprint makes it easy to store and transport, while still offering ample workspace for your milling projects. Whether you’re working on small parts or intricate designs, the WEN 33013 Benchtop Milling Machine provides the precision and accuracy needed for high-quality results.

Technical Specifications

| Specification | Details |

|---|---|

| Motor Power | 3/4 HP |

| Spindle Travel | 2 inches |

| Spindle Taper | MT3 |

| Table Size | 17.7 x 6.7 inches |

| Table Travel (X, Y) | 8.6 x 5.9 inches |

Discover the possibilities with the WEN 33013 Benchtop Milling Machine, the best hobby milling machine for versatile and precise milling operations. Whether you’re a woodworking enthusiast, a metalworker, or a hobbyist in search of a reliable and user-friendly milling machine, the WEN 33013 Benchtop Milling Machine is a top choice that delivers exceptional performance and value.

Grizzly G0781-4 Milling Machine

The Grizzly G0781-4 Milling Machine is the ultimate choice for hobbyists who seek top-notch quality and durability in their tools. Equipped with a powerful motor, this milling machine can effortlessly handle a wide range of milling tasks, providing exceptional performance every time.

With its versatile features, the Grizzly G0781-4 Milling Machine allows hobbyists to explore various milling techniques and achieve precise results. Whether you’re working on intricate designs or larger-scale projects, this machine delivers the accuracy and consistency you need for successful outcomes.

When it comes to hobby milling machines, the Grizzly G0781-4 stands out as a top contender. Invest in this high-quality and reliable machine, and experience the joy of working with a tool that exceeds your expectations, delivering exceptional results with every milling operation.