3D printing can be a fun and creative way to make a variety of objects. Depending on the type of 3D printer you have, you can make anything from toys and figurines to jewelry and home decor. You can also use 3D printing to make custom parts for your projects, such as replacement parts for a broken appliance or a custom-made part for a model car. 3D printing can also be used to make prototypes of products or parts, allowing you to test out a design before committing to a full-scale production.

If you’re looking for something fun to 3D print, there are plenty of options. You can find 3D models online that you can print, or you can design your own. Popular 3D printing projects include toys, figurines, jewelry, and home decor. You can also use 3D printing to make custom parts for your projects, such as replacement parts for a broken appliance or a custom-made part for a model car.

Why is 3D printing fun?

3D printing is a fun and creative way to bring ideas to life. It allows people to create physical objects from digital designs, which can be used for a variety of purposes. 3D printing is also a great way to explore new materials and techniques, as well as to experiment with different shapes and sizes. With 3D printing, you can create anything from toys to tools, and even custom parts for machines. It’s also a great way to learn about the technology and how it works.

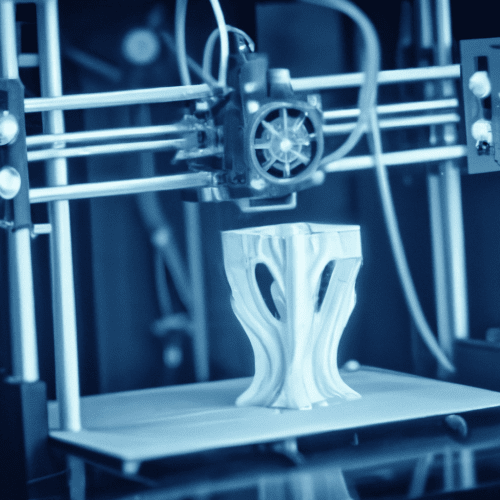

The process of 3D printing is also quite fascinating. It involves using a 3D printer to build an object layer by layer, using a variety of materials such as plastic, metal, and even wood. This process is often referred to as additive manufacturing, and it allows for a great deal of precision and detail. The end result is a physical object that is unique and can be used for a variety of purposes.

3D printing is also a great way to express yourself and your creativity.

What are the most common 3D printed items?

The most common 3D printed items are typically small, everyday objects such as phone cases, jewelry, figurines, and toys. 3D printing is also used to create larger items such as furniture, architectural models, and prosthetics. 3D printing is also used to create parts for machines and tools, such as engine components, medical implants, and aerospace components. 3D printing is also used to create prototypes for product development, as well as for rapid manufacturing of custom parts. 3D printing is also used to create molds for casting, as well as for creating intricate patterns and shapes. Finally, 3D printing is also used to create art, such as sculptures and figurines.

Can you 3D print a gun?

3D printing technology has advanced to the point where it is possible to 3D print a gun. 3D printing, also known as additive manufacturing, is a process of creating three-dimensional objects from a digital file. It involves laying down successive layers of material until the entire object is created. 3D printing has been used to create a variety of objects, including guns.

The first 3D printed gun was created in 2013 by a group called Defense Distributed. The gun, called the Liberator, was made from ABS plastic and was capable of firing a single .380 caliber bullet. Since then, 3D printed guns have become increasingly popular, with many people creating their own designs.

However, 3D printed guns are not without their drawbacks. For one, 3D printed guns are often made from plastic, which is not as strong as metal and can be prone to breaking. Additionally, 3D printed guns are often not as accurate as traditional firearms, and they can be difficult to maintain.

Can a 3D printer make a car?

Yes, a 3D printer can make a car. 3D printing technology has advanced to the point where it is now possible to print a car using a 3D printer. This process is known as additive manufacturing, and it involves using a 3D printer to layer materials such as plastic, metal, or composite materials to create a 3D object. The process is similar to traditional manufacturing, but instead of cutting and shaping materials, the 3D printer builds the object layer by layer.

The process of 3D printing a car begins with the design of the car. This is done using a 3D modeling software, which is used to create a 3D model of the car. Once the design is complete, the 3D model is then sent to the 3D printer, which prints the car layer by layer. Depending on the size and complexity of the car, the printing process can take anywhere from a few hours to several days.

Is PLA food safe?

Yes, Polylactic Acid (PLA) food packaging is generally considered safe for food contact. PLA is a bioplastic derived from renewable resources such as corn starch, tapioca roots, or sugarcane. It is a thermoplastic polymer that is biodegradable and compostable, making it an attractive alternative to traditional petroleum-based plastics.

PLA is approved for food contact by the U.S. Food and Drug Administration (FDA) and the European Food Safety Authority (EFSA). It is also certified by the Biodegradable Products Institute (BPI) and the European Bioplastics Association (EBA).

PLA is considered safe for food contact because it does not contain any toxic chemicals or additives. It is also non-toxic and non-allergenic, making it a safe choice for food packaging. Additionally, PLA is heat-resistant and can withstand temperatures up to 200°F (93°C). This makes it suitable for hot food applications such as microwavable meals.