Non-machining tooling is a type of tooling that is used in manufacturing processes that do not involve the use of a machine. This type of tooling is used to shape, form, and finish parts without the use of a machine. Non-machining tooling includes hand tools, such as hammers, chisels, files, and saws, as well as power tools, such as grinders, sanders, and drills. Non-machining tooling is used in a variety of industries, including automotive, aerospace, and medical.

Non-machining tooling is used to create parts that are too small or too complex to be machined. It is also used to create parts that require a high degree of precision or intricate detail. Non-machining tooling is often used to create parts that are too small or too complex to be machined, as well as parts that require a high degree of precision or intricate detail.

What is a non-traditional machining process?

Non-traditional machining processes are a group of processes that are used to shape and finish materials in ways that are not possible with traditional machining processes. These processes are often used to produce parts with complex geometries, tight tolerances, and intricate features. Non-traditional machining processes include electrical discharge machining (EDM), laser cutting, water jet cutting, electrochemical machining (ECM), and abrasive jet machining (AJM).

EDM is a process that uses electrical sparks to erode material from a workpiece. It is used to produce parts with complex shapes and tight tolerances. Laser cutting is a process that uses a focused beam of light to cut and shape materials. It is used to produce parts with intricate features and tight tolerances. Water jet cutting is a process that uses a high-pressure stream of water to cut and shape materials. It is used to produce parts with complex geometries and intricate features.

ECM is a process that uses an electrolyte solution and electrical current to erode material from a workpiece.

What is non-conventional machining process with example?

Non-conventional machining processes are a group of machining processes that are used to remove material from a workpiece in a way that is not typical of traditional machining processes. These processes are often used when traditional machining processes are not suitable for the material or the desired shape of the workpiece. Examples of non-conventional machining processes include electrical discharge machining (EDM), electrochemical machining (ECM), laser machining, and ultrasonic machining.

Electrical discharge machining (EDM) is a process that uses electrical sparks to erode material from a workpiece. This process is often used to machine hard materials that are difficult to machine with traditional machining processes. EDM is also used to create intricate shapes and features that would be difficult to create with traditional machining processes.

Electrochemical machining (ECM) is a process that uses an electrolyte solution and an electrical current to erode material from a workpiece. This process is often used to machine hard materials that are difficult to machine with traditional machining processes.

What is the difference between traditional and non-traditional machining?

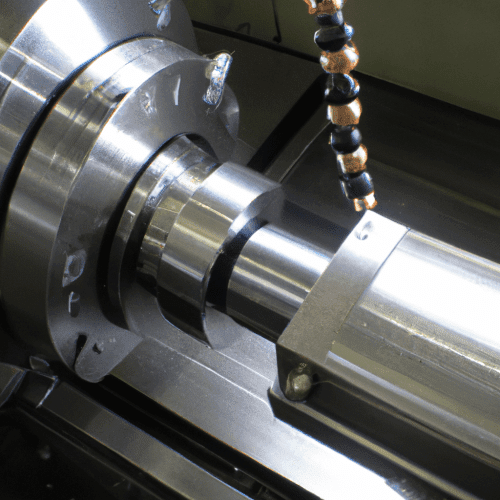

Traditional machining is a manufacturing process that involves the use of cutting tools to remove material from a workpiece in order to shape it into a desired form. This process is typically used to produce parts with complex shapes and tight tolerances. Traditional machining processes include turning, milling, drilling, grinding, and sawing. These processes are typically used to produce parts with a high degree of accuracy and repeatability.

Non-traditional machining is a manufacturing process that does not involve the use of cutting tools to remove material from a workpiece. Instead, non-traditional machining processes use energy sources such as electricity, heat, or chemical reactions to shape the workpiece. Examples of non-traditional machining processes include electrical discharge machining (EDM), laser machining, electrochemical machining (ECM), and ultrasonic machining. These processes are typically used to produce parts with complex shapes and tight tolerances, but they are not as accurate or repeatable as traditional machining processes.

Why NTM process are selected for manufacturing?

Non-traditional machining (NTM) processes are selected for manufacturing when traditional machining processes are not suitable for the job. NTM processes are used to produce parts with complex shapes and geometries that are difficult to produce with traditional machining processes. NTM processes are also used to produce parts with high precision and accuracy, as well as parts with tight tolerances. NTM processes are also used to produce parts with high surface finish quality, as well as parts with high wear resistance. NTM processes are also used to produce parts with high strength and durability, as well as parts with high corrosion resistance. NTM processes are also used to produce parts with high dimensional stability, as well as parts with high thermal stability. NTM processes are also used to produce parts with high electrical conductivity, as well as parts with high electrical insulation. NTM processes are also used to produce parts with high chemical resistance, as well as parts with high thermal shock resistance. NTM processes are also used to produce parts with high fatigue resistance, as well as parts with high impact resistance.

Which NTM process has highest material removal rate?

The Non-Traditional Machining (NTM) process with the highest material removal rate is Electrical Discharge Machining (EDM). EDM is a process that uses electrical sparks to erode material from a workpiece. It is a very precise process that can be used to machine very hard materials, such as tungsten carbide, and can be used to machine complex shapes with very tight tolerances. EDM is capable of removing material at a rate of up to 1 cubic inch per minute, making it the NTM process with the highest material removal rate.

EDM works by using an electrode to create a spark between the workpiece and the electrode. The spark erodes the material from the workpiece, and the electrode is moved to create the desired shape. The process is very precise and can be used to create very intricate shapes with very tight tolerances. The process is also very fast, and can be used to machine large volumes of material in a short amount of time.