Plasma cutters require a gas to operate, and the type of gas used depends on the type of plasma cutter. Generally, air plasma cutters use compressed air, while high-end plasma cutters use a combination of gases such as oxygen, nitrogen, argon, and hydrogen. Air plasma cutters are the most common type of plasma cutter and are the least expensive to operate. They are also the most versatile, as they can cut a variety of metals, including steel, aluminum, and stainless steel. High-end plasma cutters, on the other hand, are more expensive to operate, but they are capable of cutting thicker and harder metals, such as titanium and Inconel. The combination of gases used in high-end plasma cutters also allows for a higher cutting speed and a cleaner cut.

Can you use CO2 for plasma cutter?

Yes, you can use CO2 for a plasma cutter. Plasma cutters use a combination of electricity and gas to cut through metal. The gas used in a plasma cutter is typically either compressed air or CO2. CO2 is a more expensive gas to use in a plasma cutter, but it is also more efficient and produces a higher quality cut. CO2 is a better choice for cutting thicker metals, as it produces a more focused and hotter arc. The hotter arc of CO2 also allows for faster cutting speeds. The downside to using CO2 is that it requires more power to operate, so it is not as economical as compressed air. Additionally, CO2 is a heavier gas than air, so it is not as easy to transport and store.

When using a CO2 plasma cutter, it is important to ensure that the gas is clean and free of contaminants. Contaminants can cause the arc to become unstable and can lead to poor cut quality. Additionally, the gas pressure should be set correctly to ensure that the arc is stable and that the cut is of the highest quality.

What is plasma cutting gas?

Plasma cutting gas is a gas that is used in the process of plasma cutting. Plasma cutting is a process that uses a high-velocity stream of ionized gas (plasma) to cut through electrically conductive materials such as steel, aluminum, brass, and copper. The gas used in the process is typically a combination of argon, hydrogen, and nitrogen. The gas is heated to a very high temperature and then forced through a small opening in the cutting torch. This creates a high-velocity stream of ionized gas that is capable of cutting through the material. The gas is also used to cool the cutting torch and the material being cut. The type of gas used in the process depends on the material being cut and the thickness of the material. Generally, argon is used for cutting thin materials, while a combination of argon and hydrogen is used for cutting thicker materials.

Which plasma gas gives the best results for cutting mild steel?

When it comes to cutting mild steel, argon is the best choice of plasma gas. Argon is an inert gas, meaning it does not react with other elements, and is the most commonly used gas for plasma cutting. It is also the most cost-effective gas for plasma cutting, as it is readily available and relatively inexpensive. Argon is also the most efficient gas for cutting mild steel, as it produces a clean, precise cut with minimal heat input. The high thermal conductivity of argon also helps to reduce the risk of warping or distortion of the cut material. Additionally, argon is the most efficient gas for piercing mild steel, as it produces a clean, precise hole with minimal heat input.

When cutting mild steel, it is important to use the correct gas and pressure settings for the best results. Argon is the most commonly used gas for plasma cutting, and the pressure should be set to the manufacturer’s recommended settings. It is also important to ensure that the plasma torch is properly aligned and that the correct nozzle size is used for the material being cut.

How big of an air compressor do I need to run a plasma cutter?

The size of the air compressor you need to run a plasma cutter depends on the type of plasma cutter you are using, as well as the type of material you are cutting. Generally, a plasma cutter requires a minimum of 4 CFM (Cubic Feet per Minute) at 90 PSI (Pounds per Square Inch). However, if you are cutting thicker materials, you may need a higher CFM rating. For example, if you are cutting 1/4 inch steel, you may need a compressor with a rating of 6 CFM at 90 PSI. Additionally, if you are using an inverter-style plasma cutter, you may need a compressor with a higher CFM rating, as these types of plasma cutters require more air to operate.

When selecting an air compressor for your plasma cutter, it is important to consider the duty cycle of the compressor. The duty cycle is the amount of time the compressor can run before it needs to rest. If you are using your plasma cutter for extended periods of time, you may need a compressor with a higher duty cycle rating.

Can you use compressor air for plasma cutter?

Using compressor air for a plasma cutter is not recommended. Compressor air is not clean enough for a plasma cutter, as it contains moisture and other contaminants that can damage the plasma cutter and reduce its performance. Compressor air also has a lower pressure than what is required for a plasma cutter, which can cause the plasma cutter to not cut as efficiently. Additionally, the air pressure from a compressor is not consistent, which can cause the plasma cutter to not cut as accurately.

For these reasons, it is best to use a dedicated air supply for a plasma cutter. A dedicated air supply is a separate air compressor that is specifically designed for plasma cutters. This type of air supply is much cleaner than compressor air, as it is filtered and dried to remove moisture and other contaminants. Additionally, a dedicated air supply has a higher pressure than compressor air, which allows the plasma cutter to cut more efficiently and accurately.

Do plasma cutters use gas or compressed air?

Plasma cutters use a combination of gas and compressed air to create a plasma arc. The gas is typically a combination of nitrogen, argon, and hydrogen, and the compressed air is used to create a high-temperature, high-energy arc. The gas and compressed air are mixed together and then forced through a small nozzle, which creates an electric arc that is hot enough to cut through metal. The gas helps to stabilize the arc and also helps to protect the nozzle from damage. The compressed air helps to increase the temperature of the arc, which allows it to cut through thicker materials. The combination of gas and compressed air also helps to reduce the amount of heat generated by the arc, which helps to reduce the risk of damage to the material being cut.

Can nitrogen become plasma?

Yes, nitrogen can become plasma. Plasma is a state of matter in which a gas is heated to such a high temperature that the electrons become separated from the nuclei of the atoms, resulting in a collection of positively charged nuclei and negatively charged electrons. This is known as ionization. When a gas is heated to a high enough temperature, it can reach a state of ionization, which is known as a plasma. Nitrogen is a gas at room temperature, so it can be heated to a high enough temperature to reach a state of ionization and become a plasma.

The temperature at which nitrogen becomes a plasma depends on the pressure of the gas. At atmospheric pressure, nitrogen becomes a plasma at temperatures of around 10,000 K (9,730°C). At higher pressures, the temperature at which nitrogen becomes a plasma is lower. For example, at a pressure of 10 atmospheres, nitrogen becomes a plasma at a temperature of around 6,000 K (5,730°C).

What two methods are used to start a plasma arc cutting arc?

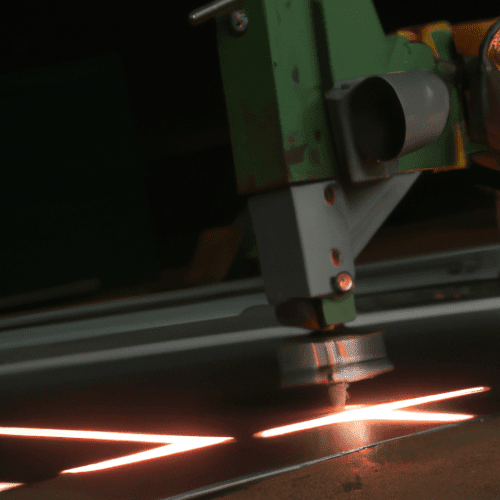

Plasma arc cutting (PAC) is a process that uses a high-velocity stream of ionized gas to cut through electrically conductive materials. The process is used to cut through metals such as steel, stainless steel, aluminum, brass, and copper. There are two main methods used to start a plasma arc cutting arc: high-frequency (HF) and contact starting.

High-frequency (HF) starting is the most common method used to initiate a plasma arc cutting arc. This method uses an electrical current to create a high-frequency electromagnetic field that ionizes the gas in the torch, creating an arc between the electrode and the workpiece. The HF current is then turned off, and the arc is sustained by the plasma arc cutting process.

Contact starting is a less common method used to initiate a plasma arc cutting arc. This method uses a physical contact between the electrode and the workpiece to create an arc. The electrode is then retracted, and the arc is sustained by the plasma arc cutting process.