CNC stands for Computer Numerical Control. It is a type of manufacturing technology that uses computers to control machine tools like lathes, milling machines, routers, and grinders. It is used to automate the production of a wide variety of parts, from small items such as jewelry to large components like aircraft wings. CNC machines are used in a variety of industries, including metalworking, automotive, aerospace, and woodworking. The advantages of CNC technology include increased accuracy, repeatability, and speed of production.

CNC Machining: A Beginner’s Guide to What It Is and How It Works

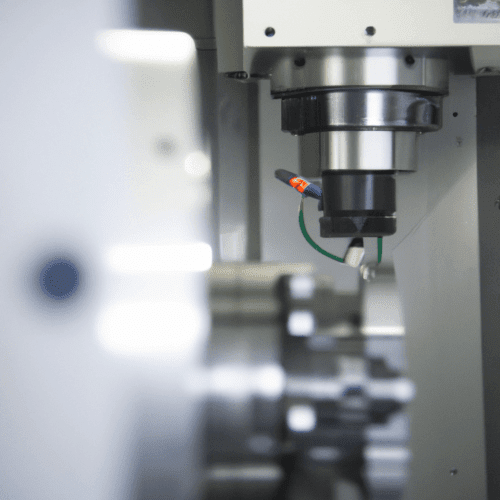

CNC machining is one of the most advanced forms of manufacturing technology available today. It is a computer-controlled automated process that uses a variety of specialized tools to shape materials into desired products. CNC machines are used in a wide range of industries including aerospace, automotive, medical, and electronics. CNC machining works by taking a workpiece, such as a block of metal or a plastic mold, and using a variety of specialized tools to shape it into the desired product. The CNC machine reads a set of instructions programmed into it by a CAD/CAM (computer-aided design/computer-aided manufacturing) software. The instructions tell the machine which paths to take as it shapes the workpiece. The CNC machine then uses its motorized tools to cut, drill, grind, and shape the workpiece to the exact specifications of the design. The process of CNC machining is highly accurate and precise. It allows manufacturers to produce complex parts with high levels of accuracy, repeatability, and speed.

This makes it an ideal choice for producing parts with complex shapes and tight tolerances. CNC machines can also be used to create several identical parts with minimal setup time, making it a cost-effective option for mass production. CNC machining is not without its challenges, however. It requires a significant investment in machinery, software, and training. CNC machines also require regular maintenance and calibration to ensure they remain accurate and efficient. Furthermore, CNC machining is labor intensive, requiring skilled workers to program and operate the machines. Despite these challenges, CNC machining is an invaluable technology for modern manufacturing. It offers a high level of accuracy and repeatability, allowing manufacturers to produce complex parts quickly and cost-effectively. It is also a safe and efficient process that can be easily automated for large production runs.

The Benefits of CNC Machining and How It Can Transform Your Business

CNC machining is a process that utilizes computer numerical control (CNC) machines to fabricate parts from a variety of materials. This technology has revolutionized the manufacturing industry, allowing for greater precision and accuracy, and creating opportunities for increased productivity. With CNC machining, businesses can produce complex parts to exacting specifications with minimal waste. CNC machining has a number of benefits that can help to transform a business. One of the primary benefits of CNC machining is that it is highly accurate. CNC machines are able to produce parts with extremely tight tolerances, meaning that the parts produced will be of a consistently high quality. This accuracy also helps to reduce the amount of material waste, as parts can be machined to the exact size and shape required. Another major benefit of CNC machining is its speed. CNC machines are able to produce parts much faster than traditional manufacturing methods, meaning that businesses can complete projects in a fraction of the time.

This can be particularly advantageous for businesses that need to produce high volumes of parts in a short period of time. CNC machining is also much more cost-effective than traditional manufacturing methods. This is due to the fact that CNC machines are able to produce parts with fewer errors than manual operations. This reduces the need for re-work and waste, resulting in significant cost savings for businesses. Finally, CNC machining is more flexible than traditional manufacturing methods. CNC machines are able to produce parts from a variety of materials, and can be programmed to produce parts in various shapes and sizes. This allows businesses to be able to quickly and easily produce parts for a variety of different applications. In conclusion, CNC machining is an invaluable technology that can help to transform businesses. It offers a range of benefits, including increased accuracy, speed, cost-effectiveness, and flexibility. These benefits can help businesses to become more competitive and efficient, allowing them to produce higher quality products in a shorter time frame.

The Advantages of CNC Machining Over Traditional Methods

CNC machining has revolutionized the way parts are machined, offering many advantages over traditional machining methods. CNC stands for Computer Numerical Control, and it is a type of machining process that uses computer-controlled functions to create parts with high precision. CNC machining can be used for a wide range of materials, including metals, plastics, and composites. The major advantage of CNC machining is its ability to produce parts with high levels of accuracy and repeatability. By using computer-controlled processes, CNC machines can produce parts with a high degree of precision, which is difficult to achieve by manual machining. CNC machining also offers a higher level of repeatability, allowing for parts to be machined with more consistency. This leads to fewer errors and more uniform parts. Another advantage of CNC machining is its speed.

CNC machines can produce parts much faster than traditional manual methods, making them ideal for producing large numbers of parts in a short amount of time. This is especially beneficial for manufacturers who need to produce parts quickly and efficiently. CNC machining also offers a greater degree of flexibility. Because the machines are computer-controlled, they can be programmed to produce parts with different geometries and dimensions. This makes them ideal for producing complex parts that would be difficult to produce with manual machining. CNC machining also eliminates the need for skilled technicians, as the machines can be programmed to perform different operations automatically. This eliminates the need for hiring and training technicians, which can be costly. Furthermore, CNC machines require less maintenance than traditional machining methods, as they are designed to be more reliable and durable. Overall, CNC machining offers many advantages over traditional machining methods. It is a cost-effective and efficient way to produce parts with high levels of accuracy and repeatability, as well as offering greater flexibility and faster production speeds. CNC machining is also more reliable and requires less maintenance, making it an ideal choice for manufacturers.

What is CAD/CAM and How Does it Relate to CNC Machining?

CAD/CAM (Computer-Aided Design/Computer-Aided Manufacturing) is a technology that combines the use of computers to design and program products or components for manufacturing. CAD/CAM systems are used to create CNC (Computer Numerical Control) programs, which are used to control CNC machines, such as mills, lathes, and routers. CNC machines are automated tools that are used to produce parts and components with high precision and accuracy. This is achieved by having the CNC machine read and interpret the numerical instructions written in the CNC program created with CAD/CAM software. The CNC program contains the instructions on how the machine should move, what tools to use, and other parameters such as feed rates and cutting speeds. CAD/CAM is a vital part of the CNC machining process, as it is used to create the CNC programs that the CNC machine needs in order to properly produce the desired parts and components. Without CAD/CAM, CNC machines would be unable to accurately and efficiently produce the parts and components needed for a wide variety of industrial applications.

Troubleshooting Common CNC Machine Issues and How to Fix Them

CNC machines are incredibly powerful tools used to automate manufacturing processes, but they also come with their own set of problems. Even the most reliable machines can suffer from malfunctions and breakdowns, and it’s important to know how to identify and troubleshoot common issues. Here are some of the most common CNC machine problems and how to fix them. One of the most common issues is a jammed spindle. If the spindle is jammed, it can be caused by a number of things including a damaged bearing, a clogged coolant line, or even a worn belt. To fix this issue, you need to first identify the cause. If it’s a damaged bearing, you’ll need to replace it. If it’s a clogged coolant line, you’ll need to clean it out. If it’s a worn belt, you’ll need to replace it. After the cause is identified and fixed, you can then reset the spindle and get it running again. Another common issue is a loose tool holder. If the tool holder is loose, it can cause the cutting tool to vibrate and move around, resulting in inaccurate cuts. To fix this issue, you need to tighten the tool holder.

First, you need to remove the cutting tool and then loosen the screws that hold the tool holder in place. Once the screws are loose, you can then adjust the tool holder until it is tight and secure. A third common issue is a faulty controller. If the controller is malfunctioning, it can cause the machine to move in erratic ways or even stop completely. To fix this issue, you need to check the wiring and make sure it’s all connected correctly. If it’s not, you may need to replace the wiring or the controller itself. These are just a few of the most common CNC machine problems and how to fix them. It’s important to remember that CNC machines are complex machines and require regular maintenance and care. If you’re having any issues with your CNC machine, it’s always best to contact a professional for help.