India is a major player in the manufacturing sector, and is home to some of the world’s leading CNC VMC (Vertical Machining Center) manufacturers. CNC VMCs are computer-controlled machines used to create intricate parts and components, and are integral to many manufacturing processes. These machines are highly efficient, precise, and reliable, and are used by a variety of manufacturers, from automotive to aerospace. CNC VMCs come in a range of sizes and configurations, from small benchtop models to large industrial-scale machines. Many of the top CNC VMC manufacturers in India specialize in producing both standard and customized machines for a wide range of applications. Some of these manufacturers also provide services such as repair and maintenance, as well as training and support. In India, some of the top CNC VMC manufacturers include Bangalore-based Ace Micromatic Group, Chennai-based Pragati Machine Tools, and Mumbai-based Sakthi Automation.

Ace Micromatic Group is a leading manufacturer of CNC machines, with an extensive range of VMCs for both large- and small-scale manufacturing. Pragati Machine Tools is renowned for its high-precision VMCs, and offers a variety of models for various industries. Sakthi Automation is another leading manufacturer of CNC VMCs, offering a wide selection of models for different applications. Other notable CNC VMC manufacturers in India include Delhi-based LMW, Hyderabad-based Bhagwansons, and Pune-based BFW. LMW is well-known for its high-performance VMCs, and has a wide range of models for different applications. Bhagwansons is a leading manufacturer of CNC VMCs, and specializes in offering customized machines for specific applications. BFW is another well-known manufacturer of CNC VMCs, and offers a variety of models for various industries. These are just a few of the leading CNC VMC manufacturers in India, and there are many more to choose from. Whether you are looking for a standard machine or a customized model, you can be sure to find the perfect VMC from one of these top Indian manufacturers.

Exploring the Benefits and Features of CNC VMC Manufacturing in India

CNC VMC (Vertical Machining Center) manufacturing in India has become increasingly popular in the last decade due to its numerous benefits and features. CNC VMC machines are versatile, efficient, and reliable, making them an ideal choice for a variety of manufacturing applications. The most notable benefit of CNC VMC manufacturing in India is its cost-effectiveness. CNC VMC machines are capable of carrying out complex machining operations at a fraction of the cost of traditional machining methods. This makes CNC VMC manufacturing an attractive option for businesses in India, especially for small and medium-sized enterprises. CNC VMC machines are also extremely efficient and productive. They are able to carry out multiple machining operations at the same time, reducing the amount of time needed to complete a project.

The machines also require very little maintenance, making them ideal for businesses that need to keep their production costs low. In addition to their cost-effectiveness and efficiency, CNC VMC machines also offer a range of features that make them even more attractive. These machines are equipped with advanced software that makes them highly customizable and able to carry out a wide range of machining operations. This includes 3D machining, drilling, tapping, and milling. CNC VMC machines are also designed to be user-friendly. The machines come with intuitive interfaces that make them easy to use. This makes them perfect for businesses that need to quickly and easily set up and operate the machines. Finally, CNC VMC machines are highly reliable and durable. The machines are designed to withstand heavy usage and are built with the highest quality components. This makes them ideal for businesses that need machines that can operate without interruption for long periods of time.

Overall, CNC VMC manufacturing in India has become increasingly popular due to its cost-effectiveness, efficiency, features, user-friendliness, and reliability. For businesses looking to reduce their production costs and increase their productivity, CNC VMC machines are an excellent choice.

How to Choose the Right CNC VMC Manufacturing Company for Your Needs

When looking for a CNC VMC manufacturing company, it is important to consider a few key factors to ensure that the company you select is the right fit for your needs. First, it is important to consider the experience and expertise of the company. Look for a company with a long history of providing high-quality CNC VMC manufacturing services, as well as a track record of successful projects. It is also important to understand the company’s capabilities in terms of available technologies, engineering services, and the level of customer support they offer. Second, it is important to consider the cost of the services offered by the CNC VMC manufacturing company. While cost should not be the only factor in your decision, it is important to evaluate if the company’s services are within your budget. Be sure to ask for an itemized quote that outlines the cost of each component of the project to ensure that you get the best value for your money.

Finally, it is important to evaluate the level of communication and customer support that the CNC VMC manufacturing company provides. You should be able to contact the company easily and receive timely responses. A good manufacturing company should be able to offer solutions to any issues you may have during the project. Additionally, the company should be able to provide you with regular updates on the progress of the project. By considering these factors, you can choose the right CNC VMC manufacturing company for your needs. With the right partner, you can be confident that your project will be completed on time and within budget.

The Latest Innovations in CNC VMC Manufacturing Technology in India

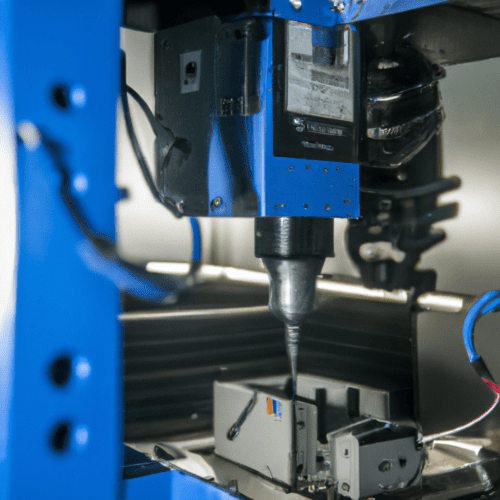

The CNC VMC (Vertical Machining Center) manufacturing technology in India is rapidly evolving to keep up with the ever-growing demand for precision machining. This technology is widely used in a variety of industries, including automotive, medical, aerospace, defense, and more. CNC VMC technology utilizes computer numerical control (CNC) to precisely control the machine’s movement, allowing for very accurate machining. CNC VMC machines are capable of producing components with tight tolerances and intricate details that are not achievable with manual machining. This technology is also very versatile, allowing for the production of a wide variety of components in a variety of materials. The latest innovations in CNC VMC manufacturing technology in India include the use of advanced sensors and feedback systems to create more precise components. These systems use a variety of sensors to detect the position of the machine and make adjustments accordingly.

This allows for faster machining speeds and increased accuracy of the components being produced. Another advancement in CNC VMC technology is the use of advanced software for programming and controlling the machine. These programs are designed to optimize machine performance and reduce cycle times, resulting in more efficient and cost-effective production. Additionally, many of these programs offer the ability to quickly and easily adjust the parameters of the machine’s operation for specific applications. Finally, CNC VMC machines are now being designed with safety features such as enclosed working areas and emergency shut-off buttons. This helps ensure the safety of operators and reduce the risk of accidents. The latest CNC VMC manufacturing technology in India is helping to create components with increased accuracy, faster turnaround times, and improved safety. This technology is helping to improve efficiency and reduce costs for a variety of industries.

Understanding the Cost Factors of CNC VMC Manufacturing in India

CNC VMC (vertical machining centers) manufacturing is a complex process that involves many different cost factors. In India, the cost of CNC VMC manufacturing depends on a variety of factors, including raw material costs, labor costs, equipment costs, and overhead costs. Raw material costs are a major factor in CNC VMC manufacturing in India. The cost of raw materials can vary widely depending on the quality and quantity of the materials needed. For example, some materials, such as aluminum, can be more expensive than others, such as steel. Labor costs also play a role in CNC VMC manufacturing in India. This includes the cost of skilled and unskilled labor, as well as the cost of the tools and machines used in the production process. Equipment costs are also a major factor in CNC VMC manufacturing in India. These costs include the cost of the actual CNC machines, as well as any additional tools and machines needed to complete the job.

The cost of the equipment can vary significantly depending on the type and size of the machines used. In addition, the cost of the necessary software and other technical support services can also add to the overall cost of the CNC VMC manufacturing process. Overhead costs are also a major factor in CNC VMC manufacturing in India. These costs include rent, insurance, utilities, and other expenses associated with the production process. These overhead costs can add up quickly and can significantly increase the total cost of the CNC VMC manufacturing process. When it comes to CNC VMC manufacturing in India, understanding the cost factors is essential. By understanding these factors, it is possible to reduce the overall cost of the manufacturing process and make the most out of the available resources.