3D printing is an exciting and innovative technology that has gained popularity in recent years. To get started with 3D printing, you’ll need to have the right hardware, software, and materials. First, you’ll need a 3D printer. There are many different types of 3D printers available, and the right one for you will depend on your budget and desired features. Make sure to research the different types of 3D printers and compare prices before making a purchase. Next, you’ll need 3D modeling software. This software will allow you to create 3D models that can be printed using your 3D printer. Popular software options include Blender and Autodesk Fusion.

Finally, you’ll need 3D printing materials. Depending on the type of printer you have, you may be able to use a variety of materials, including plastic, metal, and wood. Make sure to buy the appropriate materials for your printer. Once you have the necessary hardware, software, and materials, you’re ready to start 3D printing. Have fun creating your own 3D designs and printing them out.

What are the Benefits of 3D Printing?

3D printing is an advanced manufacturing technique that has become increasingly popular in recent years. With its ability to quickly and accurately produce complex parts and designs, 3D printing offers a number of advantages over traditional manufacturing processes. One of the most significant benefits of 3D printing is its speed. 3D printing can produce complex parts and components in a fraction of the time that traditional manufacturing processes take. This means that parts can often be printed overnight, allowing for faster product development and delivery. The accuracy of 3D printing is another major advantage. With the ability to produce parts with extremely high precision, 3D printing allows for incredibly complex components and designs that would otherwise be impossible to manufacture. The cost savings of 3D printing are also considerable.

With its ability to produce parts in a fraction of the time, 3D printing can significantly reduce the cost of production, particularly when compared to traditional methods. Finally, 3D printing is environmentally friendly. With the ability to produce parts with minimal material waste, 3D printing can help reduce the environmental impact of manufacturing processes. Overall, 3D printing offers a number of advantages over traditional manufacturing methods. With its speed, accuracy, cost savings, and environmental friendliness, 3D printing is an increasingly popular choice for manufacturing parts and components.

What Materials Can Be Used in 3D Printing?

3D printing is a process that is rapidly gaining in popularity due to the wide range of applications it can be used for. 3D printing is also known as additive manufacturing, as it involves the addition of materials to create a three-dimensional object. The materials used in 3D printing vary, and depend on the type of 3D printer being used. Common materials used in 3D printing include plastics, such as PLA, ABS, and PETG; metals such as stainless steel, titanium, and aluminum; and composites such as carbon fiber and glass fiber. Additionally, some 3D printers are able to use more exotic materials like wax, sandstone, and photopolymers. Some of these materials come in filament form, while others come in powder form which is then heated and fused together. Another popular material used for 3D printing is photopolymer resin.

This is a liquid material which is cured by UV light to form a solid object. Photopolymer resins come in a wide variety of colors, and can be used to create highly detailed objects with a smooth finish. Finally, there are a variety of bio-based materials that can be used for 3D printing, including starch-based plastics, plant-based plastics, and even wood fibers. These materials are becoming increasingly popular due to their eco-friendly nature. No matter what type of 3D printing project you are undertaking, there is likely a material that can be used to achieve the desired result. The materials used in 3D printing are constantly evolving, so it is important to stay informed of the latest developments in the field.

What Types of 3D Printers Are Available?

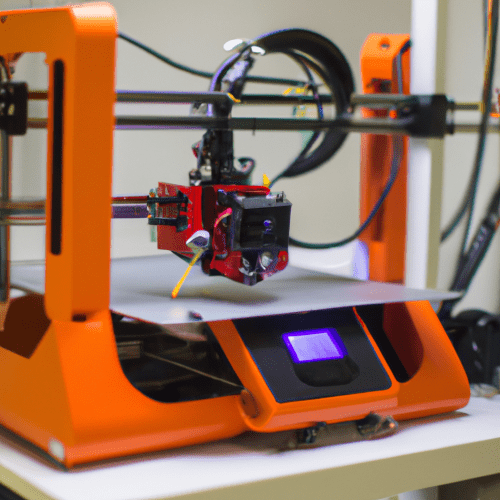

There are various types of 3D printers available on the market, ranging from budget-friendly models to professional-grade machines. The most common type of 3D printer is the Fused Filament Fabrication (FFF) model, which is the most popular and widely used 3D printing technology. These machines use a spool of plastic filament, which is heated and extruded through a nozzle to create objects layer by layer. Stereolithography (SLA) printers are another common 3D printing technology. These printers use a light source to cure a liquid plastic resin, creating highly accurate and detailed models. SLA printers are great for creating intricate objects, but the cost of the resin can be expensive. Selective Laser Sintering (SLS) printers use lasers to selectively melt and fuse powder materials, such as metal, plastic, or ceramic powders.

These printers are ideal for creating highly durable objects, but they are also the most expensive type of 3D printer. Other types of 3D printers include Multi Jet Fusion (MJF) and Digital Light Processing (DLP) printers. MJF printers use inkjet-like heads to lay down a range of materials onto a platform, while DLP printers use a projector to cure liquid resins. Both of these technologies are used to create highly detailed models, but the cost of materials and the complexity of the machines can make them expensive to use.

What Are the Steps to Setting Up a 3D Printer?

Setting up a 3D printer can be a daunting task, but following these steps will ensure a successful setup.

1. Unboxing: Carefully unbox the 3D printer and all its components. Check that all the parts and pieces are present and in good condition.

2. Assembly: Assemble the 3D printer according to the manufacturer’s instructions. This could involve putting together the frame, mounting the motors and attaching the print bed.

3. Installation of Software: Install the necessary software on your computer or laptop. This will allow you to control the 3D printer and create 3D models.

4. Calibration: Calibrate the 3D printer by adjusting the nozzle height, print bed level and extruder temperature. This will ensure that the 3D printer is printing correctly.

5. Test Print: Once the printer is properly calibrated, test it by printing out a simple model. This will help identify any potential problems before starting a more complex project. Following these steps will ensure that your 3D printer is setup properly and ready to use. It is important to take the time to properly setup the printer in order to avoid any issues in the future.

How Do I Choose the Right 3D Printer for My Needs?

Choosing the right 3D printer for your needs can be a daunting task, with so many different models, brands, and features available. To help narrow down the selection, consider a few key points to ensure you get the best 3D printer for your specific needs. First, you should consider your budget. 3D printers can range from a few hundred dollars to several thousand dollars, so it’s important to determine what your budget will allow before you start shopping. Next, think about what kind of materials you will be printing with. Some 3D printers are only compatible with certain types of plastics, while others may be able to handle a variety of materials.

Make sure the 3D printer you choose is compatible with the materials you plan to use. Finally, decide what type of features you need. Some 3D printers come with extra features such as touch screens, Wi-Fi connectivity, and built-in software. You should also consider the size of the 3D printer and how much space you have available for it in your workspace. By considering your budget, materials, and features, you should be able to find the right 3D printer for your needs. With so many different models and features available, take your time to find the perfect 3D printer for you.