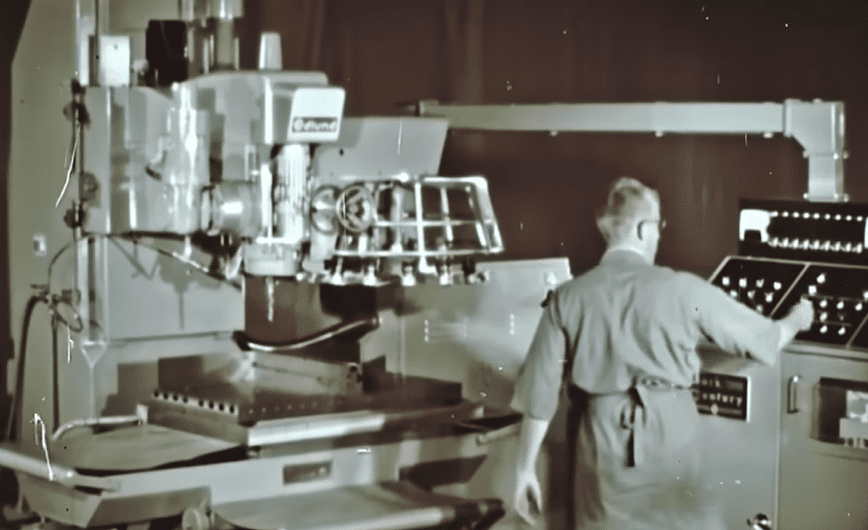

The World Before CNC: Manual Machining

Long before computers began directing machine movements, craftsmen relied on manual machining to shape, cut, and create components. This process required operators to manually control machine tools, setting the pace, direction, and depth of cuts. Manual lathes, mills, and drills demanded immense skill, focus, and precision, especially when creating intricate parts. While the results were often exceptional, thanks to the expertise of the machinists, the process was time-consuming. Moreover, replicating the same part identically multiple times was challenging, making mass production both slow and inconsistent.

Manual machining saw a limited rate of production, with a higher possibility of human error. This meant that as industries grew and the demand for standardized, rapid production increased, a new approach to machining was sought after. The need for a system that could offer precision, repeatability, and speed became clear, leading innovators to explore solutions beyond human capabilities.

The Origins of Numerical Control (NC)

The answer to these challenges began taking shape in the 1940s and 1950s with the concept of Numerical Control (NC). The idea was to automate machine tool operations using abstracted human-defined commands, and the concept was initially developed to meet the needs of the aerospace industry, which required intricate and precise parts for aircraft.

John Parsons and Frank Stulen are often credited as the pioneers of this movement. They recognized that by inputting a set of numeric coordinates into a machine, they could control its movements accurately. Their efforts resulted in the creation of punched card technology that, when fed into a machine, would dictate its operations based on the punched holes. This process greatly enhanced precision and allowed for parts to be replicated more consistently than manual machining.

To further evolve this idea, the U.S. Air Force funded Project MAC at the Massachusetts Institute of Technology (MIT) in the 1950s. This project aimed to take the NC concept and make it more universal, efficient, and user-friendly. The researchers at MIT developed the first-ever computerized numerical control (CNC) system by integrating existing NC technology with a computer. This merger transformed the world of machining forever, marking the transition from relying on punched cards to using digital computer processing. The introduction of CNC technology brought with it greater flexibility, increased production speeds, reduced error rates, and the ability to reprogram machines easily to adapt to different tasks.

Birth of CNC: Integration of Computers

As the Numerical Control (NC) method showed its potential, the next logical step in the evolution was to fully integrate the system with computers. The result was the birth of Computerized Numerical Control (CNC). The integration of computers brought a new era to machining by amplifying the capabilities of traditional NC systems.

With the use of computers, machinists could now create and modify digital designs using software, which would then be converted into commands for the CNC machines. This eliminated the need for cumbersome punched cards, streamlining the programming process. The digital format also made it easier to store, retrieve, and modify designs, leading to greater flexibility and efficiency in manufacturing.

Furthermore, the advanced computational power of computers introduced capabilities like three-dimensional machining, paving the way for the creation of more complex and intricate parts. With computers overseeing the machining process, error rates dropped significantly, and the overall quality and consistency of the finished products increased manifold.

Proliferation and Adoption of CNC Technology

The benefits of CNC technology were undeniable, and industries quickly realized its potential. The 1970s and 1980s marked a period of rapid adoption of CNC machines across various sectors. From automotive and aerospace industries to electronics and furniture manufacturing, companies everywhere began replacing their traditional machinery with CNC counterparts.

The reasons for this widespread adoption were numerous:

- Cost Efficiency: Although the initial investment in CNC machines was high, the long-term cost savings, thanks to reduced wastage and faster production times, made it a lucrative option.

- Flexibility: Unlike traditional machines, which were often dedicated to specific tasks, CNC machines could be reprogrammed to handle different jobs, making them versatile assets in a manufacturing setting.

- Precision and Repeatability: CNC machines could produce parts with a high degree of accuracy, ensuring that every piece was consistent with the last, which was especially crucial for industries where precision was paramount.

- Safety: With machines handling more of the intricate and potentially hazardous tasks, the risk to human operators was reduced.

- Innovation in Software: Parallel to the development of CNC hardware, software tools also evolved, making it easier for operators to design, simulate, and test parts before actual production. This software innovation further pushed the boundaries of what was possible with CNC machining.

The proliferation of CNC technology was also supported by the global trend of automation and the rise of Industry 4.0. As industries moved towards interconnected and smart manufacturing systems, CNC machines seamlessly fit into this new paradigm, cementing their place in modern manufacturing setups.

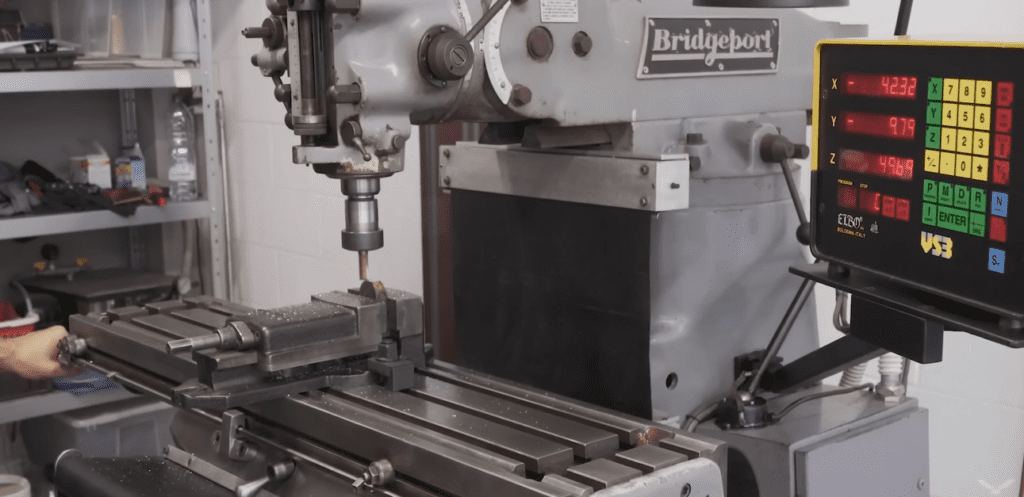

Modern CNC Innovations and Features

With the foundational principles of CNC established, the late 20th and early 21st centuries became fertile grounds for further innovations. CNC machines, which once occupied entire rooms, became more compact without sacrificing their power or precision. Modern CNC machines are often equipped with multiple tools and can switch between them automatically, which dramatically reduces the time required to produce a finished part.

Several features have been introduced to increase the capabilities and versatility of CNC machines:

- High-Speed Machining: Today’s CNC machines can operate at incredibly high speeds, allowing for quicker production without sacrificing precision.

- Multi-Axis Machining: While early CNC machines operated primarily on 2 or 3 axes, modern machines can have 5, 6, or even more axes. This allows for intricate designs and complex parts to be produced in a single setup, reducing the need for multiple machine setups and operations.

- Adaptive Machining: With the integration of sensors and advanced feedback systems, modern CNC machines can adapt to the material they are working with, adjusting speed or depth of cut in real-time.

- Touch Probing: This feature enables the machine to automatically measure the dimensions of the workpiece and adjust the machining process accordingly, ensuring maximum accuracy.

- Software Integration: Advanced computer-aided design (CAD) and computer-aided manufacturing (CAM) software allow for more intricate and precise designs to be sent directly to the CNC machine, eliminating many manual programming steps.

CNC in Non-traditional Manufacturing

While CNC technology originated in the realm of traditional machining—think metalwork and parts production—its potential did not go unnoticed in other industries. CNC has since expanded its horizons and has been adapted to cater to non-traditional manufacturing needs.

- Woodworking: CNC routers are common in woodworking shops, enabling precise cutting, carving, and shaping of wooden parts or artistic pieces.

- Glass Cutting: The delicate nature of glass requires precision, and CNC machines have been tailored to cater to this need, producing intricate and detailed designs.

- Stone and Granite Machining: Creating countertops or ornate stone pieces is now made easier with CNC machines that can carve and shape tough materials with incredible precision.

- Plasma and Laser Cutting: CNC technology has been integrated into plasma and laser cutting devices, allowing for extremely precise cuts in metals and other materials.

- 3D Printing: Arguably the most revolutionary non-traditional application, 3D printers operate on CNC principles. Instead of removing material, they add it layer by layer to produce a three-dimensional object from a digital design.

The Socio-economic Impact of CNC Machines

The advent and widespread adoption of CNC machines have ushered in profound socio-economic changes. On the industrial front, these machines have catalyzed the mass production of goods, making products more affordable and accessible to a broader segment of the population. Enhanced precision and consistency in manufacturing have driven up product quality, fueling global trade and competition.

However, there have been human costs. The automation introduced by CNC technology reduced the demand for manual machinists and operators, leading to job displacements. While some argue that CNC created new jobs related to machine programming, maintenance, and design, it’s undeniable that there was a shift in the job market from manual, labor-intensive roles to those requiring more specialized technical skills.

On the brighter side, the efficiency gains from CNC have indirectly been a boon to consumers. Reduced production costs often translate to lower prices for goods. Moreover, with the capability to produce intricate and customized designs rapidly, there’s been a democratization of design, enabling smaller manufacturers and even individuals to produce and sell bespoke items, spurring entrepreneurial ventures and niche markets.

Challenges and Future Prospects

Despite the revolutionary advancements brought about by CNC machines, the technology isn’t without its challenges. The initial investment for CNC equipment can be high, making it a barrier for small-scale manufacturers. There’s also the challenge of keeping up with rapidly evolving technology. As machines and software become more advanced, manufacturers must continually upgrade or risk obsolescence.

Environmental concerns have also arisen. CNC machines, especially older models, can consume significant amounts of power. Additionally, the waste produced, particularly from materials like plastics or certain metals, can have environmental implications.

Looking to the future, there are several promising prospects. The integration of Artificial Intelligence (AI) with CNC systems could usher in a new era of self-optimizing and even self-repairing machines. As sustainability becomes more crucial, there’s a strong push for the development of more energy-efficient CNC machines and processes that generate less waste or use biodegradable materials. The rise of Industry 4.0—the interconnectivity of machines in smart factories—will likely see CNC machines becoming even more integrated into holistic manufacturing ecosystems, where real-time data sharing and analysis will further optimize production processes.

Reflecting on the Journey from Manual Machining to Advanced CNC

Looking back on the transformative journey from manual machining to advanced CNC technologies, it is nothing short of awe-inspiring. The meticulous, hands-on process that defined early machining was an art in its own right, embodying craftsmanship, skill, and precision. However, as the industrial landscape broadened and the demand for more scalable, repeatable, and efficient manufacturing processes grew, a metamorphosis in machining unfolded.

The advent of CNC marked an epoch of accelerated productivity, reduced human error, and unparalleled precision. It bridged the gap between the artisan’s touch and mass production, enabling manufacturers to replicate intricate designs with impeccable consistency. CNC ushered in an era where complex geometries and intricate patterns could be achieved systematically, without compromising speed or accuracy.

Emphasizing the Importance of Continuous Innovation in Machining

The strides made in CNC technology underscore a fundamental truth: continuous innovation is not just beneficial but essential in the world of machining. Each advancement, from the earliest numerical control systems to today’s multi-axis, high-speed CNC machines, has been a catalyst for broader industrial growth, economic development, and the diversification of manufactured products available to consumers.

Innovation in CNC technology translates to a direct amplification of what is achievable in manufacturing. It heralds increased efficiency, cost reduction, and the capability to realize designs of heightened complexity and precision. This ongoing evolution reiterates that the future of machining and manufacturing is not fixed but is a dynamic landscape ready to be molded by the next wave of technological innovations.

The Future Outlook and Potential Implications of Further Advancements in CNC Technology

As we project into the future of CNC technology, a world of limitless possibilities unfolds. The integration of artificial intelligence and machine learning is expected to make CNC machines smarter, self-optimizing, and capable of decision-making that today still requires human intervention. Real-time data analytics, predictive maintenance, and enhanced customization are just the tip of the iceberg of what might be achieved.

In the midst of these advancements, considerations of sustainability and environmental impact will become increasingly central. Future CNC technologies might not only be evaluated based on their precision and efficiency but also on their energy consumption, waste reduction, and overall ecological footprint.