There are numerous types of machines, including mechanical, electrical, hydraulic, pneumatic, thermodynamic, and electromechanical machines. Each type of machine has its own unique characteristics and capabilities, and is used for specific tasks or purposes.

Exploring the Different Kinds of Machines: An Overview

Machines are an integral part of our modern world. They are used to automate processes, reduce human labor, and increase efficiency. There are many different types of machines, each designed for a specific purpose. This article will provide an overview of the various types of machines and their uses. One of the most common types of machines is the engine. Engines are designed to convert energy into motion. They are used in cars, airplanes, trains, and other vehicles, as well as in industrial and power generation applications. Engines come in a variety of shapes and sizes and can be powered by gasoline, diesel, electricity, or other sources of energy. Another type of machine is the machine tool. These are used for cutting, drilling, and other metalworking processes. Machine tools come in many shapes and sizes and can be used for a variety of applications. They are used in manufacturing, for machining parts, and for other industrial purposes. Robots are also a type of machine. Robots are designed to perform tasks that are too dangerous or difficult for humans to do.

They are used in a variety of industries, including manufacturing, healthcare, and agriculture. Robots can be programmed to perform a variety of tasks, from welding and painting to cleaning and delivering packages. Finally, computers are a type of machine. Computers are used to automate processes, store data, and perform calculations. They are used in a variety of industries, including finance, engineering, and healthcare. Computers are also used in many consumer applications, such as gaming, web browsing, and social media. This article has provided an overview of the various types of machines and their uses. Machines are an important part of our modern world and are used to automate processes, reduce human labor, and increase efficiency.

Comparing Mechanical, Electrical and Pneumatic Machines

Mechanical, electrical, and pneumatic machines all serve different purposes and have their own unique advantages and disadvantages. Mechanical machines are powered by human or animal energy, making them well-suited for low-powered, repetitive tasks that do not require a large amount of force. Electrical machines, by contrast, are powered by electricity, making them ideal for tasks that require a large amount of force or a high degree of accuracy.

Finally, pneumatic machines are powered by compressed air and are best suited for tasks that require large amounts of force in a short amount of time. Ultimately, the choice of machine depends on the task at hand. Mechanical machines are best for low-intensity, repetitive tasks, while electrical machines are most suitable for tasks that require a large amount of force. Pneumatic machines, meanwhile, are best for tasks that require a large amount of force in a short period of time. Depending on the specific task, any of these machines may be the best choice.

Exploring the Pros and Cons of Automated Machines

Automated machines are becoming increasingly common in the workplace, offering a range of benefits and drawbacks that must be carefully considered. On the one hand, automated machines can improve production efficiency and consistency, freeing up labor for more complex tasks. They can also reduce waste and costs, as well as helping to minimize errors. On the other hand, automation can lead to a decrease in employment opportunities, as machines can perform tasks more efficiently than humans. Furthermore, if incorrect programming or maintenance is a factor, automated machines may be prone to breakdowns and malfunctions. In order to maximize the advantages of automated machines, organizations must ensure that their use is carefully managed.

First, they should be designed to be as efficient as possible, with the right programming and maintenance protocols in place. Second, employers must consider the impact on their workforce, ensuring that any job losses resulting from automation are minimized and compensated for. Finally, organizations should ensure that any problems encountered with automated machines are swiftly identified and addressed. Overall, automated machines can provide a range of benefits if used correctly. However, it is important to carefully weigh the pros and cons before implementing them in the workplace. By taking the time to consider the full impact of automation, organizations can ensure that its use is both effective and beneficial.

The Impact of Computer-Controlled Machines on Manufacturing

Computer-controlled machines have revolutionized manufacturing, enabling increased production speeds, improved product quality, and enhanced safety. By replacing manual labor with automated processes, computer-controlled machines have enabled manufacturers to reduce operating costs and speed up production cycles. Computer-controlled machines are capable of performing complex tasks with a high degree of accuracy and consistency. Through the use of sensors and pre-programmed instructions, they can be programmed to recognize and respond to changing conditions in the manufacturing process. This allows for the production of products with greater precision and with fewer defects. Computer-controlled machines can also reduce human errors, reduce waste, and improve worker safety.

By automating production processes, the risk of operator error is greatly reduced. Additionally, computer-controlled machines can be programmed to monitor and adjust production parameters in real time to reduce material waste. Automated processes also reduce the risk of worker injury by eliminating the need for manual labor. In conclusion, computer-controlled machines have revolutionized manufacturing by enabling increased production speeds, improved product quality, and enhanced safety. By replacing manual labor with automated processes, manufacturers have been able to reduce costs, speed up production cycles, and increase the efficiency of their operations.

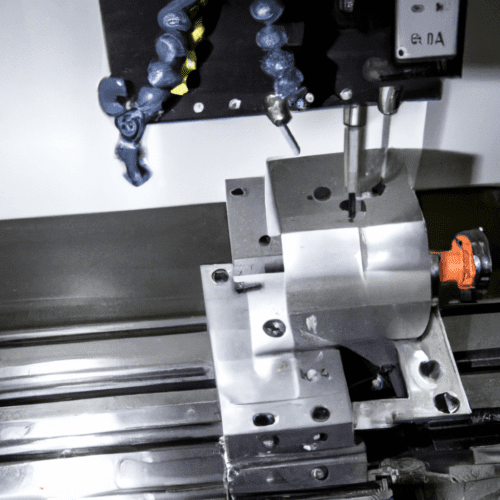

Understanding the Different Types of Machine Tools and Their Uses

The machine tool industry is a vital part of the manufacturing process, providing the technology necessary to create a variety of products. There are many different types of machine tools available, each with its own specific uses and capabilities. Understanding the different types of machine tools and their uses is essential to selecting the right tools for any given job. Lathes are one of the oldest types of machine tools, used for shaping and cutting materials such as metal, wood, and plastic. Lathes are used to create a variety of items, including furniture, musical instruments, and toys. Lathes can also be used to produce a range of precision parts for machining and manufacturing processes. Milling machines are another type of machine tool, used to cut and shape metal and other materials. Milling machines typically use rotating cutting tools to produce various components, such as gears and cams. Milling machines are also used to create slots, grooves, and other shapes on the surface of a workpiece. Drilling machines are used to create holes in a variety of materials, including metal, wood, plastic, and others.

Drilling machines use a variety of cutting tools, such as drills, taps, reamers, and drill bits. Drilling machines are commonly used in machining and manufacturing processes, as well as in construction and other applications. Grinding machines are used to shape and finish metal, plastic, and other materials. Grinding machines typically use abrasive wheels to grind, polish, and shape a workpiece. Grinding machines are used in a variety of manufacturing processes, including forming, deburring, and sharpening. Boring machines are used to create internal or external holes in materials. Boring machines use a variety of cutting tools, such as drills, reamers, and counterbores. Boring machines are commonly used in machining and manufacturing processes, as well as in applications such as pipefitting and fabrication. CNC machines are computer-controlled machines, used to create precise parts in a variety of materials. CNC machines use a variety of cutting tools, such as drills, milling cutters, and end mills. CNC machines are used in a variety of machining and manufacturing processes, including milling, turning, drilling, and grinding. Each type of machine tool has its own specific uses and capabilities. Understanding the different types of machine tools and their uses is essential to selecting the right tools for any given job. With the right tools, you can create a variety of products with precision and accuracy.