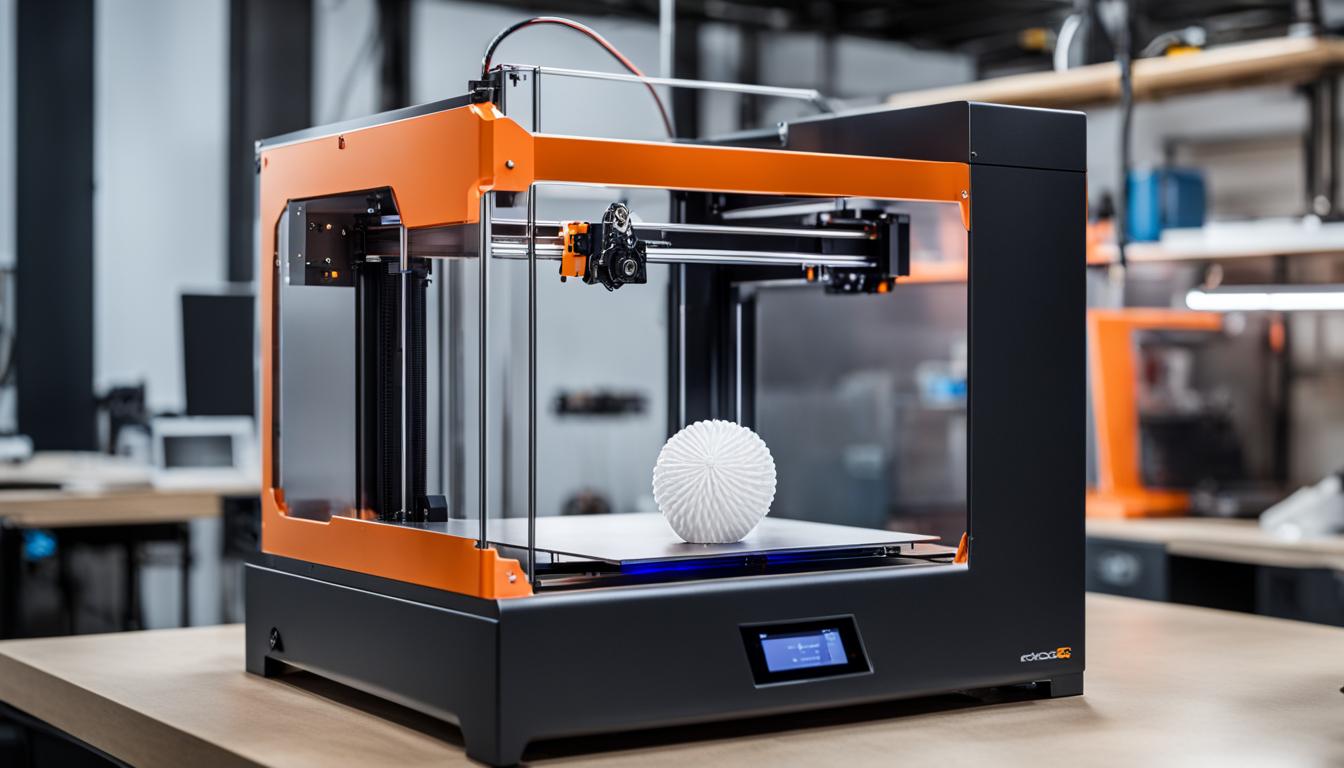

Shapeways offers a comprehensive 3D printing service that allows users to create, customize, and manufacture custom 3D models and designs. The platform provides access to over 90 materials and finishes, including plastics and metals, suitable for both prototyping and end-use products. Users can upload their 3D files directly to the Shapeways website, where they are instantly analyzed for printability. For those without 3D modeling skills, Shapeways partners with CADmore (formerly ZVerse) to offer professional design services, helping customers create manufacturable 3D files for nearly any project.

The platform also features user-friendly tools like the Custom Ring Creator and Pendant Creator, enabling even beginners to design custom jewelry without advanced 3D modeling knowledge. Additionally, Shapeways provides resources and guidelines to help users learn 3D modeling for 3D printing, covering essential aspects such as design considerations, file preparation, and material selection. With its range of services, from file optimization to manufacturing and shipping, Shapeways streamlines the entire process of bringing 3D designs to life.

- Their proprietary processes and expert operators ensure high-quality products.

- They have a wide range of materials and finishes to choose from.

- Shapeways ships to over 90 countries worldwide.

- Customers praise the ease of use and scalability of their services.

3D Printing Technologies at Shapeways

Shapeways offers a wide range of 3D printing technologies to meet diverse manufacturing needs. By collaborating with industry-leading partners such as BASF | Forward AM Technology, HP, EOS, and ExOne, Shapeways ensures access to cutting-edge equipment and materials. These technologies enable the production of custom parts and prototypes using various materials, including plastics and metals, guaranteeing exceptional quality and versatility.

BASF | Forward AM Technology

BASF | Forward AM Technology is one of the innovative 3D printing technologies available at Shapeways. It enables the creation of complex geometries in a range of materials, including thermoplastics and specialty polymers. This technology optimizes material properties, such as strength and flexibility, to deliver reliable and functional parts. The finishes achieved through BASF | Forward AM Technology are ideal for both prototyping and end-use applications.

HP Multi-Jet Fusion

Shapeways utilizes the HP Multi-Jet Fusion technology, which enables the production of high-resolution prints with exceptional accuracy and surface finish. This technology is particularly well-suited for complex geometries and fast production cycles. It offers a broad selection of materials, including various grades of nylon, allowing for the creation of durable and functional end-use parts.

EOS Selective Laser Sintering (SLS)

Shapeways leverages EOS Selective Laser Sintering technology to produce parts with exceptional detail and mechanical properties. This method uses a high-powered laser to fuse powdered materials, such as nylon and polyamide, into solid objects. EOS SLS technology allows for the creation of complex geometries and intricate designs, making it a popular choice for prototyping and small-scale production.

ExOne Binder Jetting

ExOne Binder Jetting technology is another additive manufacturing technique used at Shapeways. It enables the production of intricate metal parts with high accuracy and detail. This technology involves selectively depositing a binding agent onto metal powder layers, which are then fused together to create the final product. ExOne Binder Jetting offers a wide range of metal materials, including stainless steel and bronze, providing excellent strength and durability.

| Technology | Materials | Applications | Advantages |

|---|---|---|---|

| BASF | Forward AM Technology | Thermoplastics, Specialty Polymers | Prototyping, End-use Parts | Optimized Material Properties, Exceptional Finishes |

| HP Multi-Jet Fusion | Nylon and Other Materials | Functional Parts, Rapid Prototyping | High Resolution, Fast Production |

| EOS Selective Laser Sintering (SLS) | Nylon, Polyamide, and Others | Complex Geometries, Prototyping | Detail, Mechanical Properties |

| ExOne Binder Jetting | Metal Materials | Intricate Metal Parts | High Accuracy, Durability |

Custom Solutions with Shapeways and CADmore

Shapeways has partnered with CADmore (formerly ZVerse) to offer customized design solutions for 3D printing. With their expertise in optimizing 3D files, converting 2D files to 3D, and creating application-specific designs, they provide tailored services to meet individual needs. Whether you have an existing 3D file that requires optimization or a 2D file that needs to be transformed into a 3D model, CADmore can assist you in creating the perfect design for your project.

The CADmore portal provides an intuitive platform for communication, allowing you to easily collaborate with expert designers. Through this portal, you can submit your project requirements, share files, and receive same-day design quotes. The team of designers at CADmore is available to guide you through the entire design process, ensuring that your vision is brought to life.

From large-scale replicas to functional mechanical parts, CADmore’s services have been praised by satisfied customers. Their expertise in 3D design and commitment to quality have helped businesses and individuals achieve their goals with remarkable success.

Benefits of Shapeways CAD Partnership:

- Optimization of existing 3D files

- Conversion of 2D files to 3D

- Creation of application-specific designs

- Seamless communication through the CADmore portal

- Same-day design quotes

- Expert guidance throughout the design process

Materials and Manufacturing Options at Shapeways

When it comes to 3D printing, Shapeways offers an extensive selection of materials that cater to various applications. With over 90 materials to choose from, customers can find the perfect match for their specific needs. Whether you require versatile plastic, durable steel, lightweight aluminum, or even precious metals, Shapeways has got you covered.

Each material offered by Shapeways possesses unique properties that make it suitable for different purposes. From flexible and impact-resistant plastics to strong and corrosion-resistant metal alloys, you can find the ideal material to bring your designs to life.

Shapeways understands that manufacturing requirements can differ from project to project. That’s why they provide options for both additive manufacturing and traditional manufacturing processes. Whether you need rapid prototyping or mass customization capabilities, Shapeways has the expertise and resources to handle it all.

Through additive manufacturing, Shapeways can create complex shapes and intricate details with precision and efficiency. This technology allows for the production of highly customized and functional parts, making it ideal for prototyping and low-volume manufacturing.

On the other hand, traditional manufacturing techniques are suitable for projects that demand larger production volumes or specific material properties that might not be achievable through 3D printing alone. Shapeways can employ techniques such as CNC machining, injection molding, and casting to meet these requirements.

Take a look at the table below for a quick overview of the materials and manufacturing options available at Shapeways:

| Material | Additive Manufacturing | Traditional Manufacturing |

|---|---|---|

| Versatile Plastic | ✅ | ✅ |

| Steel | ✅ | ✅ |

| Aluminum | ✅ | ✅ |

| Precious Metals | ✅ | ❌ |

As you can see, Shapeways offers a comprehensive range of materials and manufacturing options to suit any project’s needs. Whether you’re looking for the flexibility of additive manufacturing or the scalability of traditional manufacturing, Shapeways has the solutions to bring your ideas to life with exceptional quality.

Next, let’s explore how Shapeways allows you to create complex 3D printed products from start to finish.

Creating Complex 3D Printed Products with Shapeways

Shapeways empowers users to bring their vision to life by creating complex 3D printed products from start to finish. Whether you already have a 3D model or need assistance in creating one, Shapeways offers a range of options to meet your specific needs. You can upload your 3D files directly or collaborate with Shapeways’ expert designers to create custom designs.

The 3D printing process at Shapeways involves a thorough analysis of the file for printability. If any issues arise, Shapeways provides customized feedback or assistance in regenerating the file to ensure optimal results. This meticulous approach ensures that your design is translated into a high-quality, functional 3D printed product.

Quality manufacturing is a top priority at Shapeways. They employ rigorous inspections, proprietary processes, and skilled 3D printing operators to ensure the utmost precision and detail in every print. By leveraging advanced technology and expertise, Shapeways delivers products that meet the required specifications and performance standards.

One advantage of working with Shapeways is their extensive range of materials, offering over 90 options to choose from. This allows you to select the material that best suits the desired characteristics and functionality of your product. From versatile plastics to metals and even precious materials, Shapeways provides a diverse material selection for your specific application.

To give you a better understanding of the process, here is an overview of the steps involved:

- Upload or create your 3D model: Whether you have a ready-to-print 3D file or need assistance in creating one, Shapeways supports both options.

- File analysis: Shapeways analyzes the 3D file to identify any potential issues and provide customized feedback or assistance in optimizing the design for 3D printing.

- Material selection: Choose from Shapeways’ wide range of materials to find the one that best suits your requirements in terms of aesthetics, strength, and functionality.

- Production: Once the design is finalized and the material selected, Shapeways’ expert operators will handle the 3D printing process using their state-of-the-art equipment and proprietary processes.

- Quality inspection: Shapeways ensures the final product meets the highest quality standards through thorough inspections and meticulous attention to detail.

- Delivery: Your finished 3D printed product will be carefully packaged and shipped to your location, ready to be put to use.

Creating complex 3D printed products has never been easier or more accessible than with Shapeways’ advanced 3D printing capabilities. Whether you’re a professional designer, engineer, or hobbyist, Shapeways provides the tools, expertise, and resources to turn your ideas into reality.

Explore the possibilities and start creating your custom 3D printed products today.

Design Guidelines and Tutorials for 3D Printing

Shapeways understands the importance of optimizing 3D designs for the best possible outcomes. That’s why they provide a comprehensive set of design guidelines and tutorials to assist users in their 3D printing journey. These resources cover various aspects, from prototype modeling to quality management, ensuring that users can create successful 3D prints that meet their desired specifications.

By following Shapeways’ design guidelines, users can ensure that their 3D printed parts are functional and visually appealing. The guidelines provide detailed instructions on design considerations, such as minimum wall thickness, overhangs, clearances, and more. By adhering to these guidelines, users can optimize their designs for successful 3D printing and avoid common pitfalls.

To further support users, Shapeways offers a range of tutorials that provide step-by-step instructions and tips for creating outstanding 3D prints. These tutorials cover topics such as file preparation, design optimization, and advanced techniques. Whether users are beginners or experienced designers, these tutorials provide valuable insights that can enhance their design skills and enable them to maximize the capabilities of Shapeways’ 3D printing services.

Sample Design Guidelines

| Design Considerations | Guidelines |

|---|---|

| Minimum Wall Thickness | For plastic materials, the minimum wall thickness should be at least 0.7 mm to ensure structural integrity. However, specific materials may have different requirements. |

| Overhangs and Supports | Overhangs greater than 45 degrees may require supports. It is recommended to design with appropriate angles and orientations to optimize printing. |

| Clearances and Interlocks | To ensure proper assembly and functionality, consider adding appropriate clearances and interlocks in your design. The specific tolerances should depend on the material and printing technology chosen. |

| File Formats | Supported file formats include STL, OBJ, and VRML. Check the specific guidelines for each material and technology to ensure compatibility. |

These guidelines are just a glimpse into the comprehensive set of resources provided by Shapeways. By leveraging these guidelines and tutorials, users can optimize their 3D designs, improve printability, and achieve exceptional results with Shapeways’ state-of-the-art 3D printing technologies.

Contact Sales and Start Your 3D Printing Project with Shapeways

Are you ready to bring your 3D printing project to life? Look no further than Shapeways, the industry leader in custom manufacturing solutions. Our team of experts is here to guide you through the process, from project initiation to final production. Whether you need prototypes, custom parts, or mass production, we have the knowledge and resources to meet your unique requirements.

Getting started is easy. Simply reach out to our dedicated sales team and let us know the details of your project. Fill out our contact form on the Shapeways website and provide us with as much information as possible. This will allow us to understand your needs and provide personalized assistance every step of the way.

At Shapeways, we pride ourselves on our extensive experience in 3D printing and manufacturing. By working with us, you can leverage our expertise to make your project a success. Our wide range of manufacturing options ensures that we can meet various needs and budgets. Whether you’re a small business looking to prototype a new product or a large corporation in need of mass production, we have the solutions for you.

Don’t wait any longer to turn your ideas into reality. Contact our sales team at Shapeways today and let us help you navigate the world of 3D printing. With our commitment to quality and customer satisfaction, we are confident that we can deliver the manufacturing solutions you need for a seamless and successful project.