BCN3D Technologies is a leading provider of 3D printing solutions, known for their commitment to precision and performance. With their innovative approach, BCN3D Technologies is pushing the boundaries of what can be achieved with 3D printing technology.

Key Takeaways

- BCN3D Technologies is a leader in the field of 3D printing solutions.

- They are known for their commitment to precision and performance.

- BCN3D Technologies is pushing the boundaries of what can be achieved with 3D printing technology.

BCN3D’s Vision for Additive Manufacturing

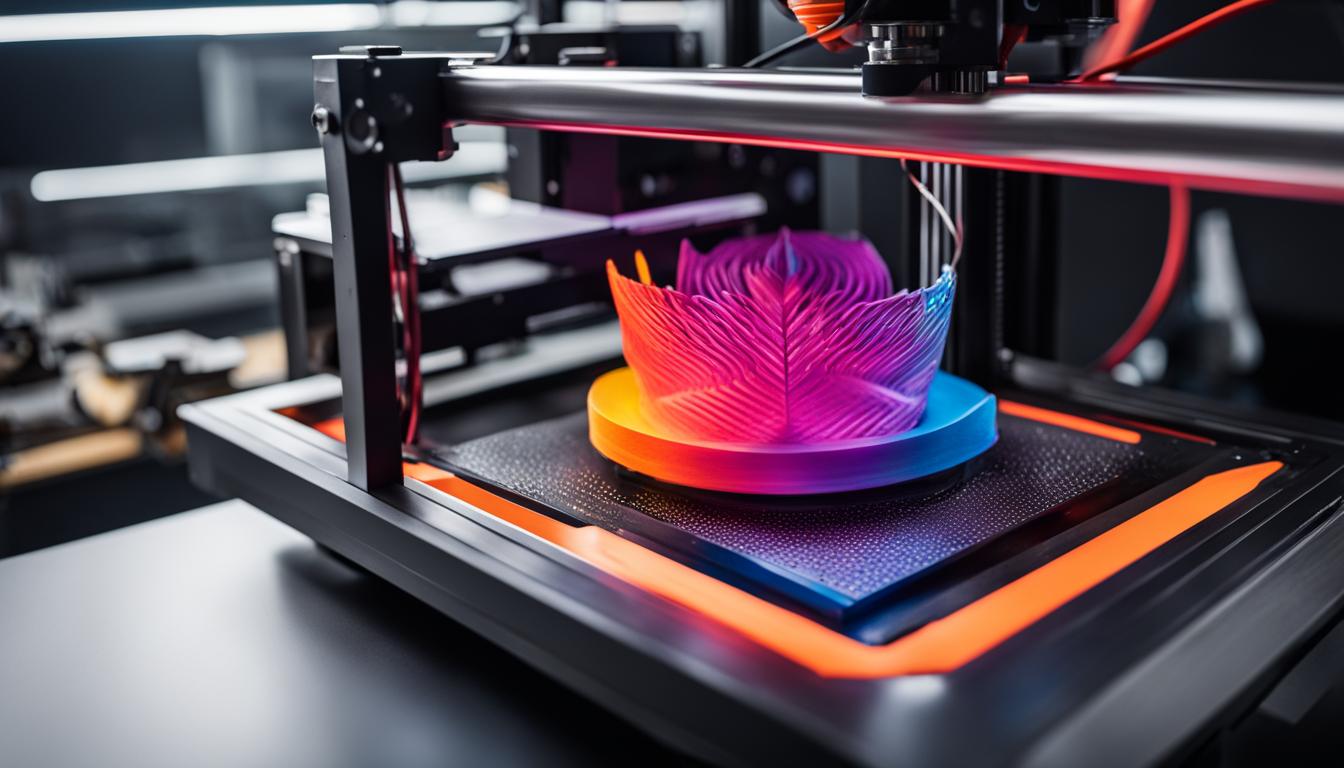

In the rapidly evolving manufacturing landscape, BCN3D Technologies has a bold vision for the future. They believe that additive manufacturing, also known as 3D printing, will revolutionize the industry, enabling greater manufacturing autonomy and unlocking new possibilities for innovation. With their commitment to precision and performance, BCN3D is at the forefront of driving this transformative change.

With additive manufacturing, BCN3D envisions a world where manufacturers and innovators have the autonomy to build end-use parts with enhanced productivity and flexibility. This technology empowers them to bring their ideas to life, iterate designs rapidly, and produce functional prototypes and final products with ease.

BCN3D believes that additive manufacturing is the future of manufacturing. It offers numerous advantages over traditional manufacturing methods, including faster production cycles, reduced waste, and the ability to create highly complex geometries. By embracing additive manufacturing, businesses can streamline their operations, reduce costs, and stay ahead of their competition in an increasingly dynamic market.

To realize this vision, BCN3D is continuously pushing the boundaries of additive manufacturing technology. They are committed to developing state-of-the-art 3D printers and innovative solutions that empower individuals and businesses to unlock the full potential of additive manufacturing. Through their cutting-edge products and dedication to customer satisfaction, BCN3D aims to shape the future of manufacturing.

BCN3D’s New Additive Manufacturing Technology

BCN3D Technologies has been diligently working on the development of a groundbreaking new additive manufacturing technology over the past three years. This innovative technology aims to achieve manufacturing autonomy, revolutionizing the way products are made. It is a significant departure from BCN3D’s current Fused Filament Fabrication (FFF) platform, opening up new possibilities for creators and innovators.

Partnering for Success

In their pursuit of excellence, BCN3D Technologies has collaborated with industry leaders to refine and test their new additive manufacturing technology. One of their valuable partners is Arkema, a renowned material partner known for their expertise in advanced materials. Through this collaboration, BCN3D is able to access cutting-edge materials that are specifically tailored for their new technology, ensuring optimal performance and exceptional results.

Testing the Limits

To further validate the capabilities of their new technology, BCN3D has enlisted the expertise of esteemed beta testers, including Saint Gobain, an automotive manufacturer, and Prodrive, a motorsport company. These prominent industry players will rigorously test the technology in real-world applications, providing invaluable feedback and insights. This rigorous testing phase ensures that BCN3D’s new additive manufacturing technology will meet the highest standards and deliver exceptional performance.

The collaboration with material partner Arkema and the extensive beta testing conducted with esteemed industry partners demonstrates BCN3D’s unwavering commitment to innovation and user-centric design. Through these partnerships and rigorous testing, BCN3D is refining their technology to meet the immediate and future needs of creators and manufacturers.

Continue reading to learn about BCN3D’s commitment to accessibility and sustainability in additive manufacturing.

BCN3D’s Commitment to Accessibility and Sustainability

BCN3D Technologies understands the vital role that accessibility and sustainability play in the manufacturing industry. They believe that 3D printing technologies offer unique solutions to address these crucial issues, providing greater flexibility and immediacy in production while minimizing environmental impact. BCN3D is dedicated to making 3D printing more accessible to a wider audience, fostering a competitive local industry, and mitigating the drawbacks of delocalization.

Advancing Accessibility

BCN3D is committed to breaking down barriers and making 3D printing accessible to all. By developing user-friendly printers that deliver exceptional quality, they empower individuals and businesses to bring their ideas to life. The intuitive interfaces and seamless workflows of BCN3D printers ensure that even beginners can easily navigate the world of 3D printing.

To further enhance accessibility, BCN3D provides comprehensive customer support and resources, including online tutorials, troubleshooting guides, and a vibrant community forum. They are dedicated to helping users overcome any challenges they may encounter along their 3D printing journey.

Pioneering Sustainability

Sustainability is at the core of BCN3D’s philosophy. They recognize the urgent need to reduce waste and environmental impact in the manufacturing industry. Through their commitment to sustainability, BCN3D promotes responsible production and consumption, aiming to create a more sustainable future for all.

BCN3D’s 3D printing technologies facilitate sustainable practices by enabling precise and localized manufacturing. By producing objects on-demand, wasteful overproduction can be avoided, reducing the carbon footprint associated with transportation and warehousing. Additionally, BCN3D actively explores the use of eco-friendly materials and promotes recycling initiatives within the 3D printing community.

In alignment with their sustainability efforts, BCN3D embraces circular economy principles. They strive to develop printers and materials with durability and recyclability in mind, ensuring that end-of-life products can be easily and responsibly recycled or repurposed.

The Role of 3D Printing in Local Industry

BCN3D recognizes that fostering a competitive local industry is vital for economic growth and innovation. By making 3D printing accessible to a wider audience, BCN3D aims to revitalize local manufacturing ecosystems. This democratization of manufacturing encourages entrepreneurship, stimulates job creation, and reduces reliance on distant suppliers, thereby enhancing economic sustainability.

Furthermore, by providing localized production capabilities, BCN3D contributes to the reduction of supply chain disruptions and logistical complexities. This resilience in the face of unforeseen challenges enhances the competitiveness and adaptability of local industries.

BCN3D’s commitment to accessibility and sustainability is exemplified in their comprehensive range of 3D printing solutions. These solutions empower individuals, businesses, and communities to embrace the benefits of additive manufacturing while working towards a more accessible, sustainable, and competitive future.

The CIM UPC: Advancing Additive Manufacturing

The CIM UPC (Center for Industrial and Technological Development of the Universitat Politècnica de Catalunya) is at the forefront of advancing additive manufacturing and digital manufacturing. With a focus on research, innovation, technology transfer, and training in the field of 3D printing, the CIM UPC is dedicated to driving the evolution of this transformative technology.

The CIM UPC engages in a wide range of activities to promote additive manufacturing. They collaborate with industry partners and academic institutions to develop prototypes for critical surgeries, pushing the boundaries of what is possible in the healthcare field. Their work also extends to the accessibility of digital fabrication, allowing more individuals to harness the power of additive manufacturing for their specific needs.

In addition, the CIM UPC provides customized 3D printing equipment and solutions to meet the unique requirements of industries and businesses. By tailoring their offerings to specific applications, they empower organizations to leverage additive manufacturing for rapid prototyping, small-batch production, and beyond.

Internships and simulations are also offered at the CIM UPC’s Pilot Plant facility, providing valuable hands-on experience and training opportunities for individuals interested in additive manufacturing and digital manufacturing. These programs contribute to the development of a skilled workforce in this rapidly evolving field.

The CIM UPC’s expertise and contributions in additive manufacturing have positioned them as pioneers in the industry, driving innovation and shaping the future of manufacturing. Their commitment to advancing the capabilities and applications of additive manufacturing is paving the way for new possibilities across a wide range of industries.

CIM UPC’s Additive Manufacturing Technologies

| Technology | Description |

|---|---|

| Stereolithography (SLA) | A high-precision 3D printing technology that produces parts with excellent surface finish. |

| Fused Filament Fabrication (FFF) | A cost-effective approach to 3D printing that extrudes layers of thermoplastic material to build objects. |

| Selective Laser Sintering (SLS) | A method that uses a laser to fuse powdered material, creating strong and functional parts. |

| Polyjet | A technology that produces prototypes with multiple materials and colors simultaneously, allowing for the creation of complex geometries. |

| CNC Machining | A subtractive manufacturing process that uses computer-controlled machines to shape and refine products. |

| Silicone Molds | The production of molds using silicone materials for casting various designs and shapes. |

| Metrology | The science of measurement, ensuring dimensional accuracy and quality control in manufacturing processes. |

Additive Manufacturing Technologies at CIM UPC

The CIM UPC offers a comprehensive range of additive manufacturing technologies to cater to various engineering and industrial needs. These advanced technologies enable precise and efficient production of parts with different requirements. Let’s explore some of the key additive manufacturing technologies available at CIM UPC:

Stereolithography (SLA)

Stereolithography, also known as SLA, is a 3D printing technique that uses a photosensitive resin cured by a UV laser to create high-precision and smooth surface finish parts. SLA is particularly suitable for applications where intricate details and fine features are required.

Fused Filament Fabrication (FFF)

Fused Filament Fabrication, commonly referred to as FFF or FDM (Fused Deposition Modeling), is a popular and cost-effective additive manufacturing technology. It works by extruding thermoplastic material layer by layer, allowing for the production of functional parts with good mechanical properties. FFF is widely adopted in various industries due to its versatility and affordability.

Selective Laser Sintering (SLS)

Selective Laser Sintering, or SLS, is a 3D printing technology that uses a high-power laser to selectively fuse powdered material, typically nylon, into functional parts. SLS offers excellent strength, durability, and good accuracy, making it ideal for applications requiring functional prototypes and end-use parts with complex geometries.

Polyjet

Polyjet technology utilizes inkjet printheads to deposit photopolymer materials layer by layer. It enables the production of parts with multiple materials and colors, making it well-suited for creating models with complex structures, realistic textures, and smooth surfaces. Polyjet technology is widely used in industries such as design, art, and healthcare.

CNC Machining

CNC (Computer Numerical Control) machining is a subtractive manufacturing process that involves cutting and shaping the material to create a desired part. CIM UPC offers CNC machining services, enabling the production of precise and custom parts from various materials like metals, plastics, and composites.

Silicone Molds

Silicone molds are a cost-effective solution for reproducing complex or intricate parts. CIM UPC provides silicone molding services, allowing for the creation of multiple identical parts from a single master pattern. This technique is commonly used in industries such as automotive, consumer goods, and medical devices.

Metrology

Metrology plays a crucial role in additive manufacturing by ensuring the accuracy and quality of the produced parts. CIM UPC offers metrology services, including dimensional measurement, quality control, and validation of 3D-printed parts, contributing to the overall reliability of the manufacturing process.

To meet the diverse needs of different industries and projects, CIM UPC’s additive manufacturing technologies, combined with their expertise, offer a comprehensive solution for precision production and innovation.

Applications of Additive Manufacturing

Additive manufacturing, also known as 3D printing, is a versatile technology that finds applications in various fields. From engineering and industry to architecture, construction, food, and medicine, additive manufacturing has revolutionized the way products are designed, prototyped, and manufactured.

Engineering and Industry

In the field of engineering and industry, additive manufacturing plays a crucial role in prototyping and final part production. The ability to quickly and cost-effectively create functional prototypes allows engineers to iterate and test designs before committing to mass production. Additive manufacturing also enables the production of complex geometries, reducing assembly requirements and optimizing part performance.

Architecture and Construction

In architecture and construction, additive manufacturing opens up new possibilities for design and construction methods. From creating intricate architectural models to fabricating building components, 3D printing allows for greater design freedom and customization. Additionally, the use of additive manufacturing in construction can help streamline processes, reduce material waste, and lower construction costs.

Food

The food industry has also embraced additive manufacturing technologies. From creating intricate chocolate designs to personalized confections, 3D printing enables chefs and food companies to add unique and artistic touches to their culinary creations. Additionally, additive manufacturing has the potential to revolutionize food production, allowing for customized nutrition and addressing specific dietary needs.

Medicine

In medicine, additive manufacturing has made significant advancements in areas such as prosthetics, implants, and surgical planning. Patient-specific medical devices can be produced using 3D printing, ensuring a precise fit and improved patient outcomes. Additive manufacturing also plays a role in regenerative medicine, enabling the creation of bio-printed tissues and organs for transplantation.

The applications of additive manufacturing are vast and continue to expand as the technology evolves. From engineering to industry, architecture to construction, and food to medicine, additive manufacturing is shaping the future of innovation and production.

CIM UPC’s Additive Manufacturing Services

The CIM UPC offers a wide range of additive manufacturing services, specializing in prototype manufacturing and rapid prototyping. Leveraging their expertise in additive manufacturing technologies, they cater to diverse project needs and deliver exceptional results.

Prototype Manufacturing

At CIM UPC, prototype manufacturing is a core focus. They understand the critical role of prototypes in the product development process, allowing companies to test and validate their ideas before committing to full-scale production. CIM UPC’s additive manufacturing services provide the agility and speed required to bring concepts to life efficiently, reducing time-to-market and accelerating innovation.

Rapid Prototyping

Rapid prototyping is the cornerstone of CIM UPC’s additive manufacturing capabilities. By leveraging cutting-edge additive manufacturing technologies, they empower businesses to iterate and refine their designs quickly. CIM UPC’s rapid prototyping services enable engineers and designers to explore multiple iterations, make design improvements, and ultimately create high-quality and functional prototypes with precision and accuracy.

Innovation through Additive Manufacturing Technologies

CIM UPC’s commitment to innovation drives their use of advanced additive manufacturing technologies. They stay at the forefront of industry advancements, utilizing technologies such as Stereolithography (SLA), Fused Filament Fabrication (FFF), Selective Laser Sintering (SLS), and Polyjet to deliver exceptional results. This ensures that clients benefit from the latest manufacturing techniques, resulting in innovative and groundbreaking products.

Personalized Processes and Close Support

As a trusted partner, CIM UPC prioritizes personalized processes and provides close support throughout the additive manufacturing journey. From the initial idea to the final product, their team works closely with clients, offering guidance, expertise, and technical assistance at every step. This collaborative approach ensures that customer requirements are met, and the final output aligns with their vision and goals.

Combining Knowledge and Technology for Innovation

By combining deep industry knowledge and cutting-edge additive manufacturing technologies, CIM UPC creates a synergy that drives innovation. They constantly push the boundaries of what is possible, exploring new materials, techniques, and applications to deliver meaningful and innovative products. CIM UPC’s unwavering commitment to innovation positions them as a leading player in the additive manufacturing landscape.

| Additive Manufacturing Technologies | Benefits |

|---|---|

| Stereolithography (SLA) | Precision and high surface finish capabilities |

| Fused Filament Fabrication (FFF) | Cost-effective production and versatility |

| Selective Laser Sintering (SLS) | Functional part production and wide material choices |

| Polyjet | Complex geometries and multi-material capabilities |

BCN3D’s Commitment to Quality and Design

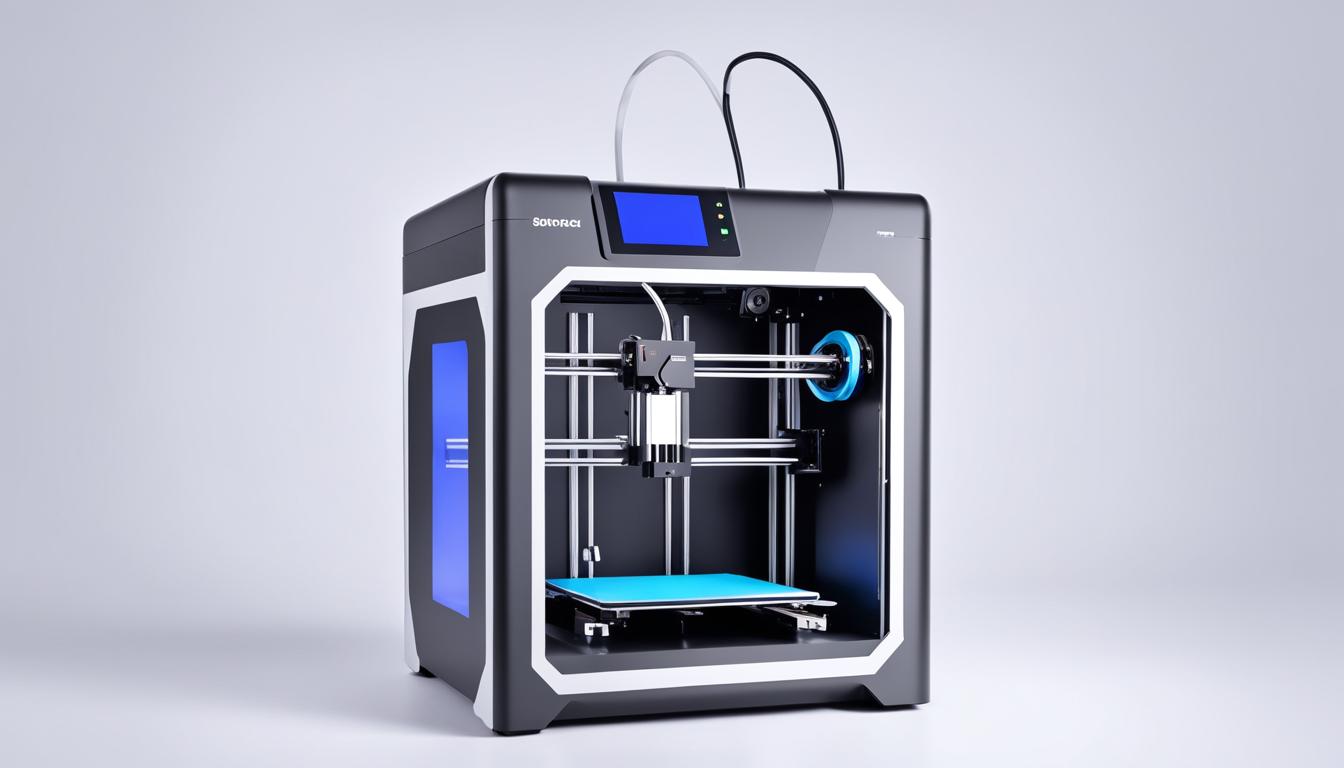

BCN3D Technologies prioritizes delivering high-quality 3D printers that are meticulously designed with incredible attention to detail. Every step of the design and development process is carefully executed to ensure optimal performance and unparalleled precision. BCN3D’s dedication to quality is reflected in the robust, efficient, versatile, and adaptable printers they produce, meeting the exact requirements of creators and innovators.

Quality Design Process

The design process at BCN3D Technologies is rigorous and comprehensive. It involves thorough investigation, prototyping, and testing to achieve exceptional outcomes. Every element of their printers, from the hardware to the software, is meticulously crafted to deliver reliable and high-performance results. BCN3D’s printers undergo stringent quality control measures to meet the highest standards of excellence.

Customer-Centered Approach

BCN3D Technologies is known for its customer-centered approach. They prioritize understanding the needs of their users and incorporating those requirements into the design and functionality of their printers. By closely engaging with their customers, BCN3D ensures that their printers effectively address the demands of various industries and applications. The result is a customer-focused product that empowers users to bring their ideas to life.

Design Features

BCN3D printers are equipped with cutting-edge features and technology that enhance the printing experience. From dual extrusion systems to advanced print settings, BCN3D printers enable users to achieve intricate and complex designs with ease. The printers are designed for versatility, allowing creators to work with a wide range of materials and applications. BCN3D’s commitment to design excellence ensures that their printers deliver exceptional performance, durability, and reliability.

| Key Design and Quality Features of BCN3D Printers | Benefits |

|---|---|

| Robust construction | Ensures durability and stability during printing |

| Precise calibration system | Provides accurate and consistent prints |

| Dual extrusion capability | Enables multi-material and multi-color printing |

| Intuitive touchscreen interface | Simple and user-friendly operation |

| Open filament system | Offers flexibility in material selection |

| Smart support technology | Efficient and easy-to-remove supports |

BCN3D as Co-Innovators

At BCN3D Technologies, co-innovation is at the heart of everything we do. We believe in the power of collaboration and actively seek partnerships with visionaries who are revolutionizing various industry fields. Together, we co-create groundbreaking ideas and solutions that have the potential to transform the way things are made.

By combining our expertise in 3D printing technology with the fresh perspectives of our partners, we foster an environment of innovation and drive change in the manufacturing industry. Our goal is to contribute to the advancement of industry fields through co-innovation, forging new pathways and pushing the boundaries of what is possible.

Innovative Partnerships

BCN3D Technologies collaborates with forward-thinking companies and organizations that share our passion for innovation. Through these partnerships, we work together to develop cutting-edge solutions that address the evolving needs of different industries. Our partners bring unique insights and expertise to the table, enhancing our co-innovation efforts and ensuring that our products and services exceed expectations.

Whether it’s in healthcare, automotive, aerospace, or any other industry, we are committed to creating meaningful and impactful innovations that drive progress. We believe that by fostering partnerships and co-innovation, we can bring about positive change and shape the future of manufacturing.

Join us on this co-innovation journey and let’s create groundbreaking ideas together!

Customer-Centric Approach of BCN3D

BCN3D Technologies is dedicated to ensuring customer satisfaction and fulfilling their individual needs. With a focus on putting the customer first, BCN3D adopts a customer-centric approach in all aspects of their business. They strive to design printers that are not only robust and efficient but also empower users to transform their ideas into reality.

BCN3D understands that every customer is unique, with specific requirements and goals. Therefore, they offer personalized user support and guidance throughout the entire journey. Whether it’s assisting with printer setup, troubleshooting, or providing tips and tricks for optimal performance, BCN3D is committed to delivering exceptional user support.

Furthermore, BCN3D takes customer needs seriously and continuously strives to improve their products and services based on valuable feedback. By actively listening to their customers, BCN3D ensures that their printers and solutions align with the evolving demands of the industry.

BCN3D’s customer-centric approach is backed by a team of dedicated professionals who are passionate about fostering strong relationships with their customers. Through prompt communication, timely assistance, and ongoing support, BCN3D aims to provide a seamless and satisfying experience for every user.

BCN3D not only builds cutting-edge technology but also builds trust, ensuring that customers receive the attention and care they deserve.

Customer Satisfaction

BCN3D’s commitment to customer satisfaction is evident in the way they prioritize the needs and expectations of their users. By delivering high-quality products, providing personalized support, and actively seeking feedback, BCN3D aims to exceed customer expectations and ensure their utmost satisfaction.

User Support

BCN3D’s user support team is readily available to provide comprehensive assistance to users at every stage of their 3D printing journey. From setup and calibration to troubleshooting and advanced techniques, BCN3D’s support ensures that users can fully harness the power of their printers.

Meeting Customer Needs

BCN3D recognizes that each customer has unique needs and requirements. They take pride in developing printers and solutions that cater to a wide range of applications, from rapid prototyping to functional part production. By offering versatile and customizable options, BCN3D ensures that customers can find the perfect fit for their specific needs.

| Customer-Centric Approach | Description |

|---|---|

| 1. Focus on Customer Satisfaction | BCN3D prioritizes customer satisfaction by delivering high-quality products and exceeding expectations. |

| 2. Personalized User Support | BCN3D provides personalized assistance and guidance to users throughout their 3D printing journey, ensuring a seamless experience. |

| 3. Continuous Improvement | BCN3D actively seeks feedback from customers to improve their products and services, keeping them aligned with evolving needs. |

| 4. Trust-Building | BCN3D builds trust with customers by promptly addressing their queries, providing timely assistance, and fostering strong relationships. |

Connect with BCN3D

Stay informed and up-to-date with the latest developments, product releases, and industry news from BCN3D Technologies by subscribing to their newsletter. By subscribing, you’ll receive regular updates directly to your inbox, ensuring that you never miss out on important information.

BCN3D values open communication and is committed to building a strong relationship with their community of creators and innovators. Their newsletter is designed to keep you informed about the exciting advancements in 3D printing technology, as well as provide insights into the latest trends and applications in the industry.

Subscribing to the BCN3D newsletter is easy. Simply visit their website and enter your email address to start receiving their updates. Don’t miss out on the opportunity to stay connected with BCN3D Technologies and be at the forefront of the 3D printing revolution.