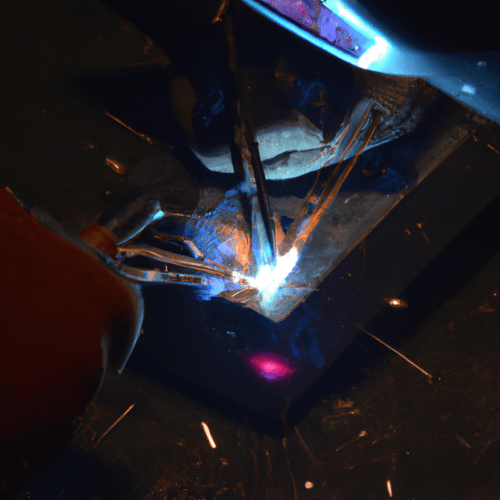

Welding is a process that involves joining two or more pieces of metal together by melting them together. To weld, you need a few key components: a welding machine, a welding rod, a welding helmet, and protective clothing.

The welding machine is the most important component of the welding process. It is used to generate the heat and electricity needed to melt the metal and join the pieces together. The welding machine is usually powered by electricity, but some machines are powered by gas.

The welding rod is the metal that is used to join the two pieces of metal together. It is usually made of a metal alloy, such as steel or aluminum. The welding rod is heated up by the welding machine and then applied to the two pieces of metal to be joined.

The welding helmet is a protective piece of equipment that is worn by the welder to protect their eyes and face from the intense heat and light generated by the welding process. The helmet also helps to protect the welder from sparks and other debris that may be created during the welding process.

Finally, protective clothing is also necessary when welding. This includes a welding jacket, welding gloves, and welding boots. The clothing helps to protect the welder from the intense heat and sparks that are created during the welding process.

In summary, welding requires a welding machine, welding rod, welding helmet, and protective clothing in order to be successful. With the right equipment and safety precautions, welding can be a safe and effective way to join two pieces of metal together.

What do you need for welding?

Welding is a process that involves joining two pieces of metal together by melting them together. In order to weld, you will need a few essential items.

First, you will need a welding machine. This machine will provide the power to heat the metal and melt it together. The type of welding machine you need will depend on the type of welding you are doing. For example, if you are doing arc welding, you will need an arc welding machine. If you are doing MIG welding, you will need a MIG welding machine.

Second, you will need welding rods. These rods are made of a metal alloy and are used to fill the gap between the two pieces of metal being welded. The type of welding rod you need will depend on the type of welding you are doing.

Third, you will need a welding helmet. This helmet is designed to protect your eyes and face from the intense heat and light generated by the welding process. It is important to wear a welding helmet when welding to protect yourself from injury.

How long does it take to learn to be a welder?

Learning to be a welder can take anywhere from a few months to several years, depending on the type of welding you are learning and the level of proficiency you wish to achieve. Generally, the most basic welding techniques can be learned in a few months, while more advanced techniques may take up to a year or more to master. Additionally, if you are looking to become a certified welder, you may need to complete an apprenticeship program, which can take up to four years.

The amount of time it takes to learn welding also depends on the type of welding you are learning. For example, if you are learning arc welding, you may need to spend more time learning the basics of the process, such as setting up the equipment and understanding the safety protocols. On the other hand, if you are learning gas welding, you may need to spend more time mastering the technique of controlling the flame and the speed of the weld.

Is welding a hard thing to learn?

Welding is a skill that requires a great deal of practice and dedication to master. It is not something that can be learned overnight, and it takes time and patience to become proficient. The basics of welding involve joining two pieces of metal together using heat and pressure. This is done by melting the metal and then using a filler material to join the two pieces together. The process of welding requires a great deal of skill and knowledge of the different types of welding processes, the materials being used, and the safety precautions that must be taken.

The first step in learning to weld is to understand the different types of welding processes. There are several different types of welding processes, including arc welding, gas welding, and oxy-fuel welding. Each of these processes has its own set of advantages and disadvantages, and it is important to understand the differences between them before attempting to weld.

Once the type of welding process has been determined, the next step is to learn the basics of welding safety.

What welder should a beginner buy?

When it comes to buying a welder for a beginner, there are a few things to consider. First, you should decide what type of welding you plan to do. Different welders are designed for different types of welding, such as MIG, TIG, and Stick welding. MIG welding is the most common type of welding and is the easiest to learn, so it is a great option for a beginner. TIG welding is more precise and is used for more intricate projects, while Stick welding is the most versatile and can be used on a variety of materials.

Once you have decided on the type of welding you plan to do, you should consider the power source. Most welders are powered by either electricity or gas. Electric welders are more convenient and easier to use, but they are limited in the thickness of the material they can weld. Gas welders are more powerful and can weld thicker materials, but they require more setup and are more expensive.

How much do welders make?

Welders make a wide range of salaries depending on their experience, the type of welding they do, and the industry they work in. According to the Bureau of Labor Statistics, the median annual wage for welders, cutters, solderers, and brazers was $41,380 in May 2019. The lowest 10 percent earned less than $27,400, and the highest 10 percent earned more than $65,170.

The type of welding a welder does can have a big impact on their salary. For example, welders who specialize in underwater welding can make significantly more than welders who specialize in arc welding. Additionally, welders who work in industries such as aerospace and shipbuilding tend to make more than welders who work in other industries.

Experience is also a factor in determining a welder’s salary. Generally, welders with more experience can command higher salaries than those with less experience. Additionally, welders who have specialized certifications or training can also make more than those without.

What are the 4 things you need before welding?

Welding is a process that involves joining two pieces of metal together by melting them together. In order to do this safely and effectively, there are four key components that are necessary for successful welding.

The first component is a welding machine. This machine is used to generate the heat and electricity needed to melt the metal and join the pieces together. The machine also controls the amount of heat and electricity used, which is important for ensuring the weld is strong and secure.

The second component is a welding rod. This rod is made of a material that is compatible with the metal being welded and is used to fill the gap between the two pieces of metal. The welding rod also helps to protect the weld from oxidation and other environmental factors.

The third component is a welding helmet. This helmet is used to protect the welder’s eyes and face from the intense heat and light generated by the welding process. The helmet also helps to protect the welder from sparks and other debris that can be created during the welding process.