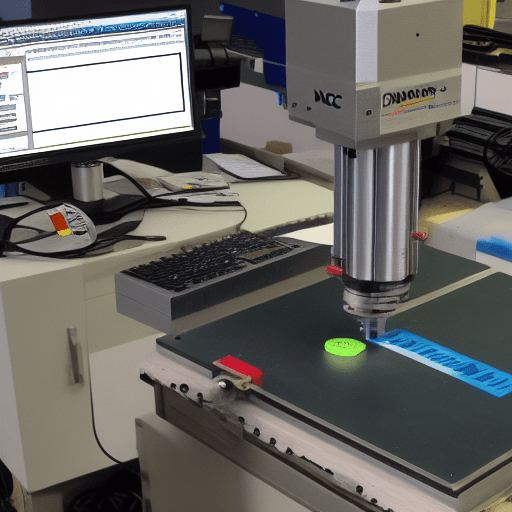

Computer Numerical Control (CNC) is a process used in the manufacturing industry that relies on computers to control machine tools. CNC machines are programmed with a computer language called G-code, which tells the machine what type of action to take on the material being machined. The G-code is typically generated from a CAD drawing or a 3D model, and is then loaded into the CNC machine. Once the G-code is loaded, the CNC machine is ready to begin machining.

The CNC machine is equipped with a cutting tool, such as a drill bit, router bit, or end mill. The cutting tool is mounted on a spindle, which is connected to a motor that rotates the cutting tool. The spindle is also connected to a servo motor, which is used to move the cutting tool in the X, Y, and Z directions. The servo motor is controlled by the G-code, which tells the servo motor how far to move the cutting tool in each direction.

The CNC machine is also equipped with a workpiece holder, which is used to hold the material being machined. The workpiece holder is connected to a servo motor, which is used to move the workpiece in the X, Y, and Z directions. The servo motor is also controlled by the G-code, which tells the servo motor how far to move the workpiece in each direction.

Once the G-code is loaded and the cutting tool and workpiece are in position, the CNC machine is ready to begin machining. The CNC machine will then move the cutting tool and workpiece in the X, Y, and Z directions according to the G-code instructions. As the cutting tool moves, it will cut away material from the workpiece, creating the desired shape.

Once the machining process is complete, the CNC machine will stop and the finished part can be removed from the workpiece holder. The CNC machine can then be programmed with a new G-code and the process can be repeated.

How is CNC programming done?

CNC (Computer Numerical Control) programming is the process of creating a program that instructs a CNC machine how to move and what operations to perform. This is done by writing a program in a specific programming language, such as G-code, which is the most common language used for CNC programming. The program is then loaded into the CNC machine, which reads the instructions and moves the machine accordingly.

When it comes to CNC programming software, there are a variety of options available. Some of the most popular software packages include Mastercam, Fusion 360, and Autodesk HSM. Each of these software packages offer a range of features and capabilities, so it is important to consider the specific needs of your project before selecting a software package. Additionally, some CNC machines may require specific software packages, so it is important to check with the manufacturer before selecting a software package.

Which software is used in CNC machine?

CNC (Computer Numerical Control) machines are automated machines that are used to cut and shape materials such as metal, wood, and plastic. The software used to control these machines is typically referred to as CNC software. This software is used to create a program that will tell the machine what to do and how to do it. The program is then loaded into the machine’s memory and the machine is ready to begin its work.

The first step of the CNC program procedure is to create a program. This is done by using a CAD (Computer Aided Design) program to create a 3D model of the part that needs to be machined. The CAD program is then used to create a G-code program, which is a set of instructions that tells the CNC machine what to do and how to do it. Once the G-code program is created, it is loaded into the CNC machine’s memory and the machine is ready to begin its work.

What is CNC material?

CNC material is a type of material that is used in Computer Numerical Control (CNC) machining. CNC machining is a manufacturing process that uses computer-controlled machines to shape and cut materials into a desired shape or size. CNC material is typically a metal, such as aluminum, steel, brass, or copper, but can also be a plastic or composite material. The material is fed into the CNC machine, which then uses a variety of tools to cut, shape, and form the material into the desired shape or size. CNC machining is used in a variety of industries, including automotive, aerospace, medical, and consumer products.

CNC material is chosen based on the desired end product and the type of machining that will be used. For example, aluminum is often used for parts that require high strength and light weight, while steel is often used for parts that require high strength and durability. Plastic and composite materials are often used for parts that require flexibility and low cost.

What is G-code programming?

G-code programming is a language used to control automated machine tools such as CNC mills, lathes, and 3D printers. It is a numerical control language that is used to create instructions for the machine to follow. G-code is used to control the motion of the machine, as well as the speed and feed rate of the cutting tool. It is also used to control the spindle speed, coolant, and other machine functions. G-code is a very versatile language and can be used to create complex parts with intricate details.

G-code is composed of a series of commands, each of which is composed of a letter and a number. The letter indicates the type of command, and the number indicates the value of the command. For example, G00 is a rapid positioning command, and G01 is a linear interpolation command. Each command is followed by a series of parameters that define the motion of the machine.

How long does it take to learn CNC programming?

Learning CNC programming can take anywhere from a few weeks to a few months, depending on the individual’s prior experience and the complexity of the programming language. For those with no prior experience, it is recommended to start with a basic CNC programming course, which can take anywhere from a few weeks to a few months. This course will provide the student with the fundamentals of CNC programming, such as understanding the different types of CNC machines, the different types of CNC programming languages, and the basics of CNC programming. After completing the basic course, the student can then move on to more advanced CNC programming courses, which can take anywhere from a few months to a few years, depending on the complexity of the programming language.

In addition to taking a course, it is also important to practice CNC programming on a regular basis. This can be done by using a CNC simulator, which allows the user to practice programming without the need for a physical CNC machine. This can be a great way to get familiar with the different programming languages and to practice writing code.

Is CNC programming easy?

CNC programming can be a difficult skill to learn, but it is not impossible. It requires a good understanding of the CNC machine, the programming language, and the machining process. It also requires a good understanding of the material being machined and the tools being used.

CNC programming is a complex process that requires a lot of practice and patience. It is important to understand the basics of the programming language and the machine before attempting to program a CNC machine. It is also important to understand the material being machined and the tools being used.

The complexity of CNC programming depends on the type of machine being used and the complexity of the machining process. For example, a CNC milling machine requires more complex programming than a CNC lathe. Additionally, the programming language used to program the machine can vary depending on the type of machine being used.

In general, CNC programming is not an easy skill to learn. It requires a good understanding of the CNC machine, the programming language, and the machining process.

Which software is best for CNC programming?

CNC (Computer Numerical Control) machines are automated machines that are used to cut and shape materials such as metal, wood, and plastic. The software used to control these machines is typically referred to as CNC software. This software is used to create a program that will tell the machine what to do and how to do it. The program is then loaded into the machine’s memory and the machine is ready to begin its work.

The first step of the CNC program procedure is to create a program. This is done by using a CAD (Computer Aided Design) program to create a 3D model of the part that needs to be machined. The CAD program is then used to create a G-code program, which is a set of instructions that tells the CNC machine what to do and how to do it. Once the G-code program is created, it is loaded into the CNC machine’s memory and the machine is ready to begin its work.