Machining of wood is a process of cutting, shaping, and finishing wood materials to create a desired product. It is a form of woodworking that involves the use of specialized tools and machinery to cut, shape, and finish wood materials. Machining of wood can be used to create a variety of products, from furniture to musical instruments.

The process of machining wood begins with the selection of the appropriate wood material. Different types of wood have different properties, such as hardness, strength, and grain pattern, which must be taken into consideration when selecting the right material for the job. Once the material is selected, the machining process can begin.

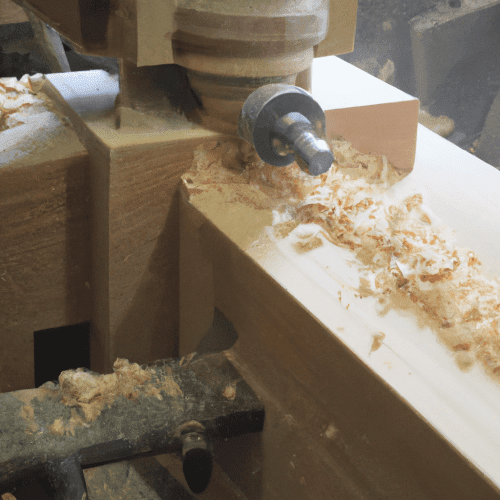

The first step in machining wood is to create a design or pattern. This can be done by hand or with the help of a computer-aided design (CAD) program. Once the design is complete, the wood is cut to the desired shape and size using a variety of tools, such as saws, routers, and lathes. The wood is then sanded and finished to create the desired product.

What is the meaning of wood machining?

Wood machining is the process of cutting, shaping, and finishing wood to create a desired product. It involves the use of various tools and machines to cut, shape, and finish the wood. This includes saws, routers, planers, jointers, and sanders. The process of wood machining can be used to create furniture, cabinetry, flooring, and other wood products. It is also used to create decorative items such as sculptures and carvings. Wood machining is an important part of the woodworking industry, as it allows for the creation of a wide variety of products. The process of wood machining requires a great deal of skill and precision, as it involves the use of various tools and machines to achieve the desired results.

Can wood be machined?

Yes, wood can be machined. Machining is a process that involves cutting, shaping, and finishing a material to create a desired product. Wood is a material that can be machined using a variety of tools and techniques. Common machining tools used for wood include saws, routers, drills, lathes, and sanders. Each of these tools can be used to cut, shape, and finish wood to create a desired product. For example, a saw can be used to cut wood into different shapes and sizes, a router can be used to create grooves and other shapes in wood, a drill can be used to create holes in wood, a lathe can be used to turn wood into round shapes, and a sander can be used to smooth the surface of wood. Machining wood can be a complex process, but with the right tools and techniques, it can be done with precision and accuracy.

What is a milling machine for wood?

A milling machine for wood is a type of machine tool used to shape and finish wood materials. It is typically used to cut, shape, and form wood into a variety of shapes and sizes. It can also be used to create intricate patterns and designs in wood. Milling machines for wood are typically used in woodworking shops and factories, and are used to create furniture, cabinets, doors, and other wood products.

Milling machines for wood are typically powered by electric motors, although some models may be powered by gasoline or diesel engines. The motor is connected to a spindle, which is the part of the machine that rotates the cutting tool. The cutting tool is usually a drill bit, router bit, or end mill, and is used to cut and shape the wood. The cutting tool is usually held in place by a collet, which is a type of clamp that holds the cutting tool in place.

The milling machine for wood is usually operated by a computer numerical control (CNC) system, which is a computer program that controls the machine’s movements.

What type of wood is used in CNC machines?

CNC machines are typically made from a variety of different materials, including aluminum, steel, and wood. The type of wood used in CNC machines depends on the application and the desired outcome. For example, hardwoods such as maple, oak, and walnut are often used for CNC machines that require high precision and accuracy, while softer woods such as pine and poplar are used for machines that require less precision. Additionally, some CNC machines are made from composite materials such as plywood, particle board, and MDF. Each type of wood has its own unique properties and characteristics, so it is important to choose the right type of wood for the job.

What is the word for cutting wood?

The word for cutting wood is sawing. Sawing is the process of using a saw to cut through wood. There are many different types of saws that can be used to cut wood, including hand saws, circular saws, jigsaws, reciprocating saws, and band saws. Each type of saw has its own advantages and disadvantages, and is best suited for different types of woodworking projects. Hand saws are the most basic type of saw and are best used for making straight cuts in thin pieces of wood. Circular saws are more powerful and can make curved and angled cuts in thicker pieces of wood. Jigsaws are best used for making intricate cuts in thin pieces of wood. Reciprocating saws are best used for making rough cuts in thick pieces of wood. Band saws are best used for making curved and angled cuts in thick pieces of wood.

How does a wood cutting machine work?

A wood cutting machine is a type of machine that is used to cut wood into various shapes and sizes. It is typically used in the construction and carpentry industries, as well as in the manufacturing of furniture and other wood products. The machine works by using a rotating blade to cut through the wood. The blade is usually made of steel or other hard material and is mounted on a spindle that is driven by an electric motor. The motor is connected to a control panel, which allows the user to adjust the speed and depth of the cut.

The wood cutting machine typically has a table that the wood is placed on. The table is usually adjustable, allowing the user to adjust the height and angle of the wood. The blade is then lowered onto the wood and the motor is activated. The blade then rotates at a high speed, cutting through the wood. Depending on the type of machine, the blade may be able to cut in a straight line or in a curved pattern.

The wood cutting machine also has a dust collection system, which collects the sawdust created by the cutting process.

What does a timber machinist do?

A timber machinist is a skilled tradesperson who works with wood and other timber materials to create a variety of products. They use a variety of tools and machines to shape, cut, join, and finish timber products. Timber machinists are responsible for creating a variety of products, such as furniture, cabinets, doors, windows, and other wooden items. They must be able to read and interpret blueprints and drawings to ensure that the finished product meets the customer’s specifications.

Timber machinists use a variety of tools and machines to shape, cut, join, and finish timber products. These tools include saws, routers, planers, jointers, sanders, and other specialized tools. They must be able to use these tools safely and accurately to ensure that the finished product meets the customer’s specifications. They must also be able to read and interpret blueprints and drawings to ensure that the finished product meets the customer’s specifications.

Can you mill wood?

Yes, you can mill wood. Milling wood is a process of cutting and shaping wood into a desired shape or size. It is typically done with a milling machine, which is a machine tool that uses a rotating cutting tool to shape and form the wood. The milling machine can be used to cut straight lines, curves, and other shapes into the wood. It can also be used to create grooves, slots, and other features.

The type of milling machine used will depend on the type of wood being milled and the desired shape or size. For example, a router is often used to mill wood for furniture, while a sawmill is used to mill large pieces of lumber. The type of milling machine used will also depend on the type of cut being made, such as a straight cut, a curved cut, or a combination of both.

The milling process begins by selecting the right type of wood for the project. The wood should be dry and free of any defects.

How does density affect the machining properties of wood?

Density is an important factor in determining the machining properties of wood. The higher the density of the wood, the harder it is to machine. This is because higher density wood has a higher proportion of hardwood fibers, which are more difficult to cut and shape than softer wood fibers. Higher density wood also has a higher proportion of lignin, which is a natural adhesive that binds the wood fibers together and makes them more difficult to cut. Additionally, higher density wood has a higher proportion of extractives, which are compounds that can interfere with the cutting process and make it more difficult.

The machining properties of wood are also affected by its grain structure. Wood with a straight grain structure is easier to machine than wood with a cross-grain structure. This is because the straight grain structure allows the cutting tool to move more easily along the grain, while the cross-grain structure can cause the cutting tool to bind and cause more friction.

Finally, the machining properties of wood are also affected by its moisture content.