Turning and milling are two distinct machining processes that differ primarily in how the workpiece and cutting tool move relative to each other. In turning, the workpiece rotates while a stationary cutting tool removes material to create cylindrical or conical shapes. This process is ideal for producing axially symmetric parts like shafts, bolts, and cylindrical components. Milling, on the other hand, involves a rotating cutting tool that moves along multiple axes while the workpiece remains stationary.

This allows for the creation of more complex geometries, including flat surfaces, contours, and intricate 3D shapes. Turning is generally faster and more efficient for producing round parts, while milling offers greater versatility for creating a wide range of shapes and features. The choice between turning and milling depends on factors such as the desired part geometry, material, production volume, and required precision.

- Turning and milling are precision machining processes with different approaches.

- Turning rotates the workpiece against a stationary cutting tool, primarily using round bar stock.

- Milling spins the cutting tool against a stationary workpiece, primarily using square or rectangular bar stock.

- Both processes involve CNC technology, produce waste material chips, and can work with metals and thermoplastics.

- Turning is best for cylindrical parts, while milling is preferred for complex geometries.

Turning and Milling Similarities

Despite their differences, turning and milling also share some similarities. Understanding these common features can provide valuable insights into the world of precision machining. Here are the key similarities between turning and milling:

1. CNC Technology:

Both turning and milling involve the use of CNC (Computer Numerical Control) technology. This advanced automation allows for precise control over the machining process, ensuring accurate and consistent results.

2. Waste Material Production:

In both turning and milling, chips of waste material are produced as the cutting tools remove unwanted features from the workpiece. This waste material, also known as swarf, is typically collected and disposed of separately.

3. Materials Compatibility:

Both turning and milling can be used to machine a wide variety of materials. Commonly machined metals include aluminum, steel, brass, copper, and titanium. Additionally, thermoplastics can also be successfully machined using these processes.

| Materials | Turning | Milling |

|---|---|---|

| Metals | ✔️ | ✔️ |

| Thermoplastics | ✔️ | ✔️ |

| Rubber and silicone | ❌ | ❌ |

| Ceramic | ❌ | ❌ |

4. Heat Generation:

Both turning and milling generate heat during the machining process. This heat can have an impact on the workpiece and the cutting tools. To mitigate the effects of heat, cutting fluid is often used. It helps to cool down the machining area and provides lubrication to reduce friction.

CNC Turning Distinctions

CNC turning is a precision machining process that offers distinct features and benefits compared to other machining methods. Understanding the unique aspects of CNC turning is crucial for manufacturers and engineers seeking efficient and precise manufacturing solutions.

Features of CNC Turning

CNC turning involves using a lathe machine, which holds the round bar stock in a chuck and rotates it at a preset speed. This rotation enables the stationary cutting tool to remove material from the surface of the workpiece, creating the desired features. CNC turning can also include:

- One spindle or main and sub-spindles: Offering the capability for additional machining operations on the same part.

- “Live” tooling: Some CNC Swiss turning machines have this feature, allowing for the creation of more complex shapes and features.

Benefits of CNC Turning

CNC turning offers several advantages that make it an attractive choice for manufacturers:

- Faster and more efficient: CNC turning is typically faster than milling when it comes to producing smaller components.

- Precision and accuracy: The rotation of the workpiece allows for accurate machining, ensuring tight tolerances and high-quality end products.

- Versatility: CNC turning can be used with a wide range of materials, including metals and thermoplastics, making it suitable for various applications.

- Cost-effective: The speed and efficiency of CNC turning contribute to cost savings in terms of production time and labor.

Overall, CNC turning is a reliable and efficient machining process that offers unique features and benefits for manufacturers. Its precision, versatility, and cost-effectiveness make it a valuable choice for creating high-quality components.

CNC Milling Distinctions

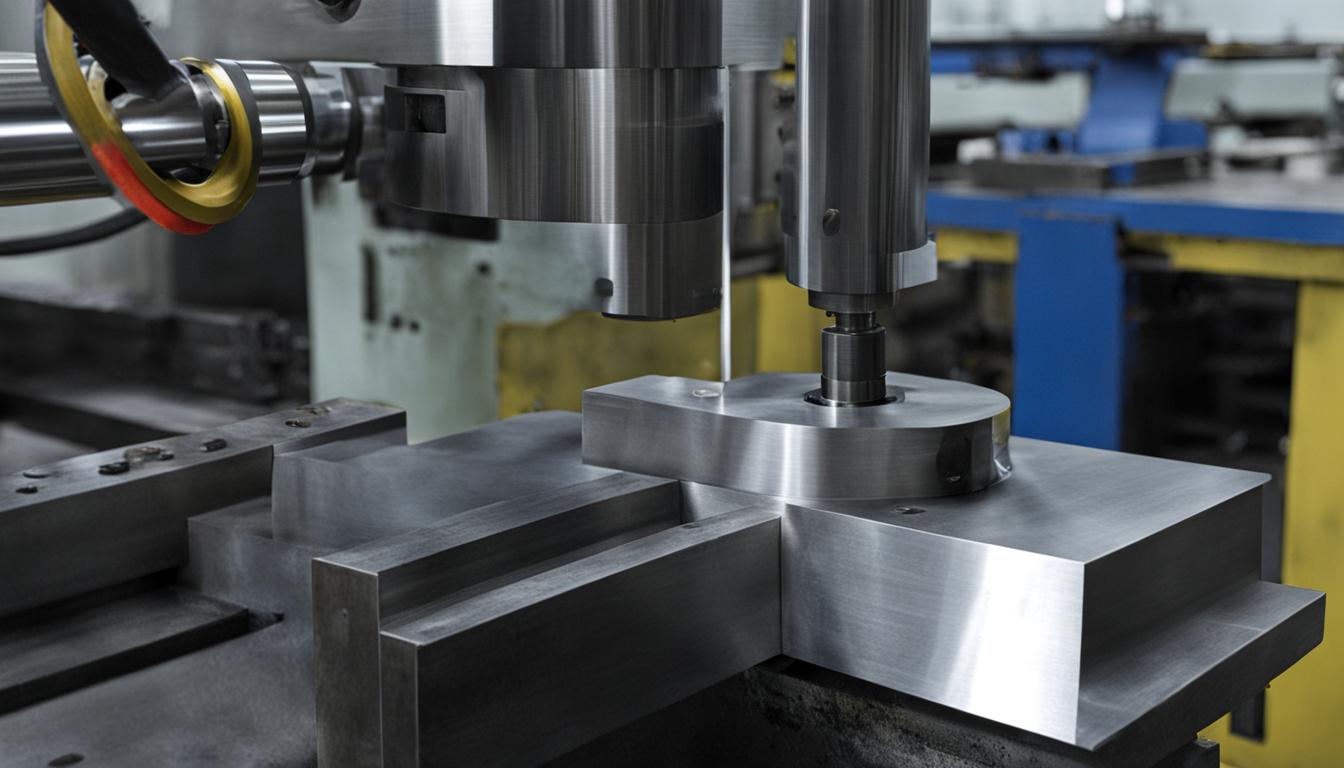

CNC milling is a precision machining process that involves the use of a milling machine to create complex shapes and designs. In this process, the cutting tool rotates and moves while the workpiece remains stationary, allowing for precise and intricate machining.

One of the main features of CNC milling is the ability to perform various milling operations to achieve different shapes and features. These operations include face milling, plain milling, and angular milling. Face milling is used to create flat surfaces, while plain milling is used for cutting straight or parallel grooves. Angular milling allows for the creation of angled surfaces and features.

The cutting tool used in CNC milling can have multiple cutting surfaces, which adds to the versatility of the process. This allows for more efficient and precise machining, as the tool can perform multiple cutting actions in a single operation.

CNC milling is particularly suitable for producing flat or sculptured surfaces on square or rectangular blocks. This makes it a popular choice in industries such as automotive and aerospace, where complex shapes and designs are often required.

| Features | Description |

|---|---|

| Precision | CNC milling offers high precision and accuracy in creating complex shapes and features. |

| Versatility | The use of multiple cutting surfaces allows for a wide range of machining operations. |

| Complexity | CNC milling is suitable for creating intricate designs and shapes. |

| Flat and Sculptured Surfaces | The process is ideal for producing both flat and sculptured surfaces on square or rectangular blocks. |

Turning Vs Milling Overview

When it comes to precision machining, turning and milling are two widely used processes. Understanding the key differences between these processes is crucial in selecting the right approach for specific manufacturing needs. Let’s take a closer look at the comparison of turning and milling, highlighting their key distinctions.

Turning Process

In turning, the workpiece rotates while the cutting tool remains stationary. This process primarily produces cylindrical or conical shapes. Turning is commonly used for manufacturing cylindrical parts, such as shafts, pins, and bolts.

Milling Process

On the other hand, milling involves spinning the cutting tool while the workpiece remains fixed. This process is ideal for creating flat or sculptured surfaces and is often used for complex geometries in industries like automotive and aerospace.

Key Differences Between Turning and Milling

- Rotational Movement: Turning involves rotating the workpiece, while milling rotates the cutting tool.

- Resulting Shapes: Turning produces cylindrical or conical shapes, while milling creates flat or sculptured surfaces.

- Part Types: Turning is typically used for cylindrical parts, whereas milling is preferred for more complex geometries.

In summary, turning and milling differ in their approach to material removal, resulting shapes, and suitable applications. Choosing between turning and milling depends on factors such as part design, desired features, and production requirements.

| Turning | Milling |

|---|---|

| Rotates the workpiece | Rotates the cutting tool |

| Produces cylindrical or conical shapes | Creates flat or sculptured surfaces |

| Used for cylindrical parts | Preferred for complex geometries |

Turning Applications and Benefits

Turning is a widely utilized precision machining process in the manufacturing industry, offering numerous applications and benefits. With its ability to produce components with cylindrical shapes, such as shafts, pins, and bolts, turning plays a crucial role in various industries.

One of the key advantages of turning is its high precision. The rotating workpiece allows for accurate machining, resulting in tight tolerances and consistent quality. This precision is essential in industries where precise measurements and dimensions are critical.

Furthermore, turning offers increased speed and efficiency, especially for smaller parts. The process is well-suited for high-volume production, allowing manufacturers to achieve faster turnaround times and enhanced productivity.

Another benefit of turning is the ability to incorporate live tooling on CNC turning machines. This enables the creation of additional features like drilled holes and small milled surfaces, expanding the range of possibilities for part design and functionality.

The table below provides an overview of some common turning applications:

| Industry | Turning Applications |

|---|---|

| Automotive | Engine components, transmission shafts, steering system parts |

| Aerospace | Landing gear components, turbine parts, hydraulic fittings |

| Medical | Surgical instruments, orthopedic implants, dental implants |

| Electronics | Connectors, terminals, sensor housings |

Image caption: Examples of precision machining applications using turning techniques.

The versatility and precision of turning make it an indispensable process in the manufacturing industry. From automotive and aerospace to medical and electronics sectors, turning plays a vital role in producing high-quality components efficiently and accurately.

Milling Applications and Benefits

Milling is a versatile precision machining process that finds extensive applications in various industries. It enables the creation of highly complex shapes and features, making it indispensable in automotive, aerospace, and medical sectors.

Milling is commonly employed in the automotive industry for producing engine components with intricate designs and tight tolerances. It allows for the precise machining of critical features in engine blocks, cylinder heads, and pistons, ensuring optimal performance and efficiency.

In the aerospace industry, milling plays a crucial role in manufacturing airframe structures, such as fuselages, wings, and landing gear components. The ability to create complex shapes and features enables the production of lightweight structures without compromising strength and durability.

Furthermore, milling is widely used in the medical industry for the production of implants, surgical instruments, and prosthetics. The precision and versatility of CNC milling machines allow for the creation of intricate geometries and customized designs, ensuring a perfect fit and functionality for medical devices.

Milling offers several benefits that make it a preferred choice for precision machining:

- High precision and tight tolerances: CNC milling ensures exceptional accuracy, making it suitable for producing critical components with strict dimensional requirements.

- Versatility: Various milling operations, such as face milling and peripheral milling, enable the creation of different shapes and features, catering to diverse manufacturing needs.

- Efficiency: CNC milling machines can remove material quickly and precisely, resulting in faster production cycles and reduced overall manufacturing time.

- Cost-effectiveness: With its ability to produce complex parts in a single setup, milling eliminates the need for additional machining processes, reducing production costs.

When it comes to precision machining with milling technology, CNC (Computer Numerical Control) plays a vital role. CNC milling machines provide unmatched control and automation, ensuring consistent and repeatable results. They are capable of executing complex toolpaths and intricate designs with minimal human intervention.

Incorporating CNC milling into manufacturing processes guarantees exceptional precision, efficiency, and the ability to create intricate components for various industries.

Milling Applications

| Industry | Applications |

|---|---|

| Automotive | Engine components, such as cylinder heads, engine blocks, and pistons |

| Aerospace | Airframe structures, landing gear components, wing sections |

| Medical | Implants, surgical instruments, prosthetics |

| Industrial | Machine components, molds, tooling |

Considerations for Choosing Between Turning and Milling

When deciding between turning and milling, there are several important factors to consider. These factors can help you make an informed decision and select the most suitable machining process for your needs.

Part Design and Required Features

The design of your part and the specific features you require play a significant role in determining whether turning or milling is the best option. Turning is well-suited for cylindrical parts, while milling is preferred for complex geometries, such as intricate shapes and sculptured surfaces.

Size of the Part and Production Volume

The size of your part and the production volume needed are also important considerations. Turning is generally more efficient and cost-effective for smaller parts, while milling is suitable for larger parts or when working with higher production volumes.

Desired Production Time

Consider the desired production time for your project. Turning is typically faster compared to milling, making it a viable choice when time is of the essence.

Material Properties

The properties of the material you are working with can also impact your decision. Different materials, such as metals or thermoplastics, may have varying characteristics that can affect the choice between turning and milling. Consider factors like hardness, brittleness, and heat sensitivity.

Cost Considerations

Finally, cost considerations should not be overlooked. The cost of machining can vary depending on factors such as setup time, tooling, and material waste. Evaluate the overall cost efficiency of turning and milling for your specific project.

By carefully considering these factors, you can make an informed decision and choose between turning and milling based on your part design, production requirements, desired production time, material properties, and cost considerations.

Examples of Turning and Milling Applications

Turning and milling are versatile machining processes that find applications in various industries. Here are some real-life examples of how these processes are used:

Automotive Manufacturing

In the automotive industry, turning is commonly used for producing engine components. Turning allows for precision machining of cylindrical parts like crankshafts, camshafts, and connecting rods. On the other hand, milling is often employed for creating complex mold cavities used in the production of automotive components.

Aerospace Industry

In the aerospace industry, turning is utilized for manufacturing precision parts, such as landing gear components. The high accuracy and surface finish achieved through turning are vital for ensuring the safety and reliability of aircraft. Milling, on the other hand, is used for creating airframe structures that require intricate designs and precise machining.

These examples highlight the versatility and importance of both turning and milling in the manufacturing sector. Whether it’s producing engine components in the automotive industry or manufacturing intricate parts for aerospace applications, turning and milling play crucial roles in creating high-quality and precise components.

These examples of turning and milling applications underscore the importance of these machining processes in various industries. From the production of engine components in the automotive sector to the intricate parts required in aerospace applications, turning and milling offer precision and versatility for manufacturing needs.

Limitations of Turning and Milling

While turning and milling are versatile machining processes, they do have some limitations. These limitations can impact the feasibility and effectiveness of using turning and milling for certain applications. Understanding these challenges and drawbacks is important for manufacturers and engineers in making informed decisions about their machining processes.

1. Limitations of Turning:

Turning is primarily focused on external features and may not be suitable for parts with complex internal geometries. The process involves rotating the workpiece against a stationary cutting tool, which limits access to internal cavities. This can make it challenging to machine intricate internal details or achieve complex shapes that require internal machining. Additionally, turning is generally more efficient for smaller components rather than large parts.

2. Limitations of Milling:

Milling may not be the most efficient process for small parts or parts with intricate internal cavities. Accessing and maneuvering the cutting tool within these confined spaces can be difficult, leading to longer machining times and increased costs. Milling is more suitable for producing flat or sculptured surfaces on square or rectangular blocks rather than cylindrical shapes. While versatile, milling is not always the ideal choice for creating certain external or internal features.

Both turning and milling processes generate heat during machining due to the friction and cutting forces involved. This heat can impact the quality of the machined part and lead to thermal distortions. To mitigate this, cutting fluids are often used to provide cooling and lubrication, but they can add to the overall costs and environmental impact of the processes.

Despite these limitations, turning and milling remain important and widely used machining processes in various industries. Manufacturers and engineers need to carefully analyze their specific requirements, part designs, and material properties to determine the most appropriate machining method.

| Limitations | Turning | Milling |

|---|---|---|

| Suitable for complex internal geometries | No | Difficult |

| Efficiency for small parts | Yes | Challenging |

| Access to intricate internal cavities | Limited | Difficult |

| Heat generation | Yes | Yes |

Future Trends in Turning and Milling

The field of turning and milling is experiencing a continuous evolution with advancements in technology. As manufacturers and engineers strive for more precise and efficient machining processes, new possibilities are emerging. Let’s explore some future trends in turning and milling that are shaping the industry.

Advancements in Turning and Milling Technologies

The introduction of advanced CNC (Computer Numerical Control) systems and software has revolutionized turning and milling. These technologies provide enhanced precision, control, and automation, resulting in higher quality finished products. CNC machines allow for complex geometries and intricate designs, pushing the boundaries of what can be achieved through turning and milling processes.

Additionally, the integration of additive manufacturing technologies with traditional machining processes is gaining momentum. Additive manufacturing, also known as 3D printing, offers unique opportunities to combine the benefits of both turning and milling. By using additive techniques to create intricate structures or features, manufacturers can reduce material waste and achieve greater design flexibility.

Emerging Technologies in Turning and Milling

Looking ahead, emerging technologies are set to further transform the turning and milling landscape. Automation, robotics, and artificial intelligence (AI) are becoming increasingly integrated into machining processes, enhancing productivity and quality.

Robotic arms equipped with advanced sensors and machine vision systems can facilitate precise material handling, tool changing, and quality control. By automating repetitive tasks, manufacturers can optimize production flow and minimize human error.

Artificial intelligence is also playing a significant role in turning and milling. AI-driven algorithms can analyze vast amounts of data to optimize cutting parameters, tool paths, and material selection. This leads to improved efficiency, reduced cycle times, and enhanced overall machining performance.

Finding the Right Machining Partner

When it comes to precision machining, finding the right machining partner is crucial for ensuring high-quality results. Selecting a precision machining company requires careful consideration of several factors: experience, capabilities, and certifications.

A reputable machining partner should have extensive experience in the industry, demonstrating a track record of delivering successful projects. Look for a company that possesses the necessary expertise in both turning and milling, as this will ensure they can cater to a wide range of machining needs.

Consider the capabilities of the machining partner, such as their technological resources and equipment. A modern and well-equipped facility indicates their commitment to staying up-to-date with the latest machining techniques and technologies.

Furthermore, certifications are an important aspect to consider. Look for machining partners who hold relevant certifications, such as ISO 9001, which demonstrate their commitment to quality and adherence to international standards.

Effective communication and collaboration are also essential for a successful partnership. Choose a machining partner who takes the time to understand your specific requirements and provides efficient and reliable machining solutions. A collaborative approach ensures that your machining partner can adapt to any changes or challenges that may arise throughout the process.