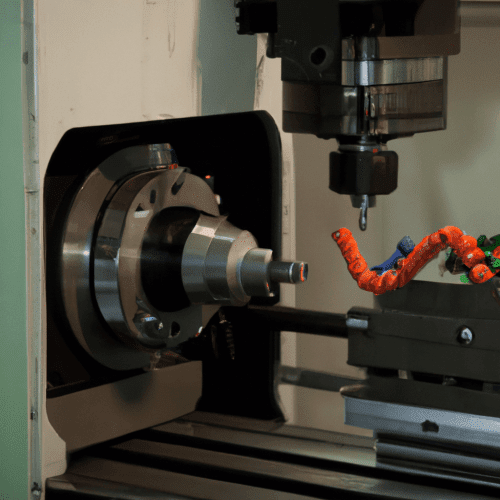

Are you in the market for a CNC grinding machine? If so, you’ve come to the right place. This comprehensive guide will help you choose the best CNC grinding machine for your needs. First, let’s cover some basics. A CNC grinding machine is a computer-controlled grinding machine that has a rotating wheel. It is capable of grinding metal, wood, and other materials in a precise and repeatable manner. It can also be used to cut through hard materials, like stone and concrete. When choosing a CNC grinding machine, you’ll want to consider the materials you’ll be working with. Do you need to grind metal, wood, or other materials?

You’ll also want to consider the size and shape of the material you’ll be grinding. This will help you determine the size and type of machine you need. You’ll also want to consider the accuracy requirements for the job. Different machines have different levels of accuracy, so it’s important to know what level of accuracy you’ll need for your project. Next, you’ll want to consider the type of machine you need. There are three primary types: manual, automated, and semi-automated. Manual machines are the most basic and require the operator to manually move the wheel to the desired position. Automated machines are more advanced and can be programmed to move the wheel to the desired position. Semi-automated machines are a combination of the two, allowing the operator to manually move the wheel but also program it to move to certain positions.

Finally, you’ll want to consider the cost. CNC grinding machines can be expensive, so it’s important to consider your budget before making a purchase. Consider the cost of the machine, as well as any additional accessories or software you may need. By following this guide, you’ll be able to make an informed decision when choosing a CNC grinding machine. When you understand your needs and consider all of the factors outlined in this guide, you’ll be able to choose the best machine for your project.

Exploring the Benefits and Features of Different CNC Grinding Machines

CNC grinding machines are an essential part of modern manufacturing, offering precision and reliability for a wide variety of applications. These machines use computer numerical control (CNC) to accurately and efficiently shape and finish materials like aluminum, steel, brass, and plastic. With the right CNC grinding machine, you can achieve a high level of accuracy and repeatability without the need for manual operation. There are many benefits and features that come with CNC grinding machines. First, they offer greater precision than manual grinding machines, allowing for more accurate and consistent results. Additionally, they are designed to be extremely reliable, reducing the risk of downtime and costly repairs.

Finally, CNC grinding machines tend to be more efficient than manual machines, as they can process multiple pieces at once. When it comes to features, CNC grinding machines can vary significantly. Some offer variable speed control, allowing the user to adjust the speed of the machine depending on the material being worked with. Others may come with programmable features, allowing the user to set up a series of operations to be performed automatically. Some machines may also come with a digital readout, displaying the current settings of the machine. Overall, CNC grinding machines offer numerous advantages over manual grinding machines. They offer greater precision, reliability, and efficiency, making them ideal for a wide range of applications. With the right machine, you can produce high-quality parts in less time and with less effort.

Comparison Shopping for CNC Grinding Machines: What to Look For

When it comes to shopping for CNC grinding machines, there are a few key factors to consider. Understanding the capabilities of the machine is the first step in selecting the right one for your application. Grinding Machine Types: There are a variety of grinding machines available, each with their own unique capabilities. Some of the most common types of grinding machines include cylindrical, surface, and jig grinding machines. It is important to understand the differences between each type to ensure that you select the right machine for your application. Grinding Machine Features: Each grinding machine will have its own set of features that will determine its capabilities. When selecting a machine, consider the features and specifications that are important to you. This could include the size of the grinding wheel, the speed of the spindle, the accuracy of the grinding, and the type of control system.

Control System: The control system is an important factor in selecting a grinding machine. There are several different types of control systems available, such as manual, CNC, and PLC. CNC systems are the most advanced and allow for the most precise grinding operations. Safety Features: Safety is an important factor when it comes to CNC grinding machines. Look for machines that have safety features such as guards and sensors to ensure that the machine is operating safely.

Price: Of course, the price of the machine is also an important factor to consider. Compare prices from different suppliers to find the best deal. These are just a few of the factors to consider when comparison shopping for CNC grinding machines. Taking the time to research and understand the features and capabilities of each machine will help you make the best decision for your application.

Money-Saving Tips for Finding the Right CNC Grinding Machine

1. Do your research: Take the time to research the types of CNC grinding machines available and the features they offer. Read customer reviews to gain insight into the quality of different products.

2. Understand your needs: Make sure you understand what you need out of a CNC grinding machine. Consider the materials you will be working with, the types of projects you do, and the budget you have available.

3. Compare prices: Shop around to compare prices between different CNC grinding machines. You can find great deals online, so be sure to compare prices from several different retailers.

4. Consider used options: Used CNC grinding machines can be a great way to save money. Make sure you do your research and inspect the machine carefully to ensure you are getting a good quality product.

5. Ask for recommendations: Reach out to people in your industry to get recommendations for CNC grinding machines. This can be a great way to get an idea of the best products on the market.

6. Consider service and support: Make sure the company you are buying from offers good customer service and support. This can make all the difference in the long run when it comes to maintenance and repairs.

CNC Grinding Machine Troubleshooting and Maintenance Tips

CNC Grinding Machine Troubleshooting and Maintenance Tips CNC grinding machines are essential tools in the manufacturing industry. Like any other equipment, they require regular maintenance and troubleshooting to ensure reliable and efficient performance. To ensure the longevity of your machine, here are some tips to help you troubleshoot and maintain your CNC grinding machine. First and foremost, regular and timely maintenance is essential. This includes checking for any signs of wear and tear, cleaning and lubricating components, and tightening bolts and other connections. Additionally, the machine should be inspected to ensure that all components are functioning properly, and any worn parts should be replaced.

When troubleshooting your CNC grinding machine, the most important step is to identify the source of the problem. To do this, it is important to inspect all the components of the machine, including the drive motors, spindle, and control system. If there is an issue with any of these components, it can cause the machine to malfunction. It is also important to check the lubrication system for any blockages or signs of wear. Proper lubrication is essential for the proper functioning of the machine. If the lubrication system is not working correctly, it can cause the machine to overheat and break down. Finally, it is important to check the grinding wheel for any signs of damage or wear. If the grinding wheel is damaged, it can cause an uneven finish on the material being processed. By following these tips, you can ensure that your CNC grinding machine will continue to function reliably and efficiently. Regular maintenance and troubleshooting can help to ensure that your machine will provide years of reliable service.