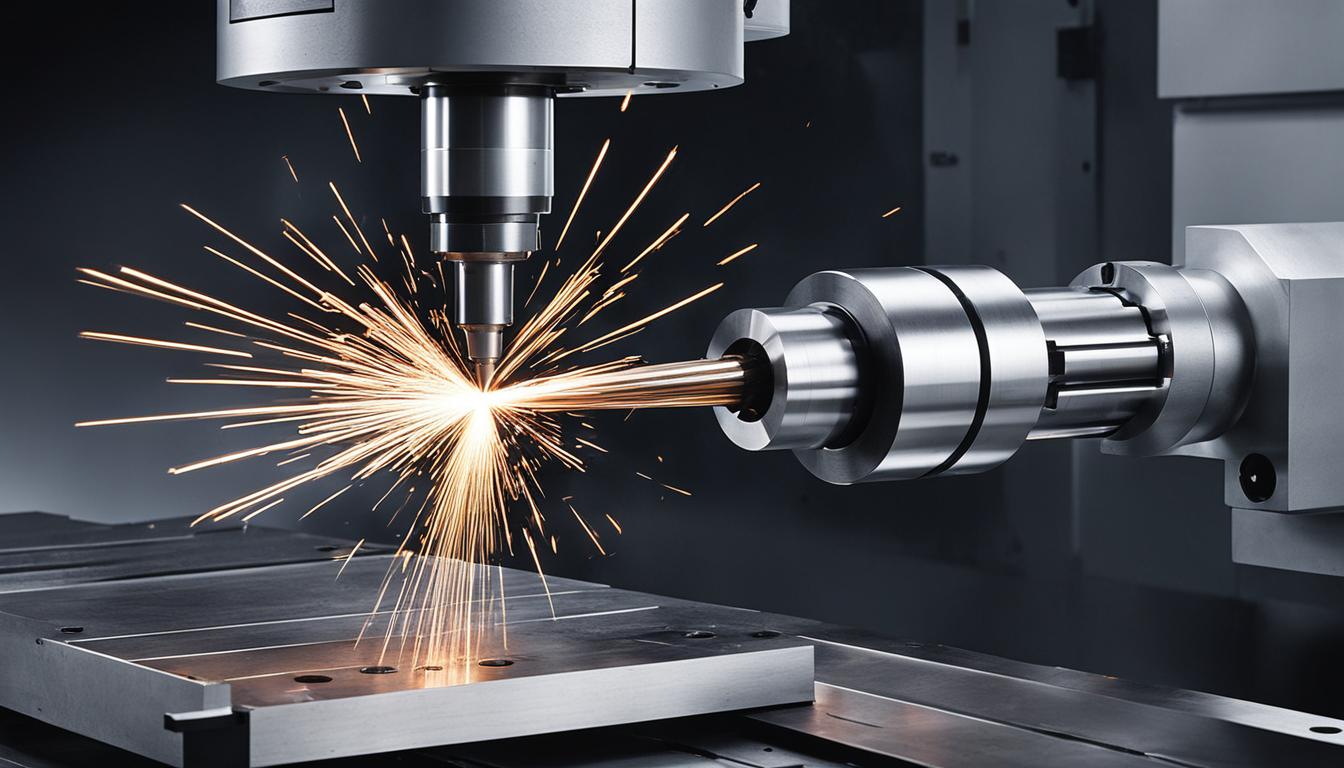

A machining center (MC) is an advanced computer-controlled machine tool used for a variety of machining operations and processes. It is a versatile and efficient solution that combines several functions into one, allowing for precise and automated manufacturing.

At its core, a machining center features an automatic tool-changing mechanism (ATC) that enables quick and seamless changes of cutting tools. This feature greatly enhances production efficiency, as it eliminates the need for manual tool changes, reducing downtime and increasing productivity.

Machining centers are capable of handling complex operations such as milling, turning, boring, and drilling. They are equipped with multiple axes, including the X-axis, Y-axis, Z-axis, A-axis, B-axis, and C-axis, which allow for precise control and movement of the cutting tool and workpiece.

The main components of a machining center include the main spindle area, taper feed mechanism, automatic tool changer (ATC) system, tool magazine, automatic pallet changer (APC) system, chip and coolant handling system, overload and wear detectors, and automatic door operation mechanism.

There are various types of machining centers available, including horizontal machining centers (HMC), vertical machining centers (VMC), and universal machining centers (UMC). Each type has its own advantages and is tailored to specific needs and applications.

Machining centers find applications in a wide range of industries, including automotive, aerospace, and general manufacturing. Their precision and automation capabilities make them indispensable for tasks such as grinding, drilling, shaping, and molding engine parts, aerospace components, and general manufacturing products.

The cost of a machining center varies depending on factors such as size, features, and capabilities. However, the benefits it brings in terms of increased productivity, efficiency, and quality make it a worthwhile investment for many businesses.

In the next sections, we will delve deeper into what a machining center is, its components, types, applications, and more. Stay tuned to unlock the full potential of this advanced tool.

What is a Machining Center?

A machining center (MC) is an advanced computer-controlled machine tool used for a variety of machining operations. Unlike traditional machines, an MC features an automatic tool-changing mechanism (ATC) for quick changes of cutting tools. This enables the machining center to handle complex operations such as milling, turning, boring, and drilling with precision and efficiency.

Machining centers are known for their versatility, accuracy, and ability to automate tasks, making them an integral part of modern manufacturing processes. By utilizing CNC (Computer Numerical Control) technology, machining centers can be programmed and controlled to perform intricate operations with optimal precision. These machines have revolutionized the manufacturing industry by enhancing productivity and reducing labor-intensive tasks, ultimately leading to faster production times and improved product quality.

Who Invented the First Machining Center?

The first machining center was invented in the early 1950s by John T. Parsons and Frank L. Stulen.

The idea was refined by the MIT Servomechanisms Laboratory, leading to the development of CNC machining centers.

The invention revolutionized the manufacturing industry by introducing automation, precision, and flexibility.

What are the Main Components of a Machining Center?

In a machining center, several components work together to ensure efficient and precise machining operations. Understanding the main components of a machining center is essential for optimizing its performance and productivity.

Main Spindle Area

The main spindle area is where the cutting tools are held and are responsible for providing rotation during machining operations. It plays a crucial role in achieving accurate cuts and smooth finishes.

Taper Feed Mechanism

The taper feed mechanism controls the depth and orientation of the cutting tools. It ensures that the tools penetrate the workpiece at the right depth and angle, resulting in precise and smooth cuts.

Automatic Tool Changer (ATC) System

The automatic tool changer (ATC) system enables quick and efficient tool changes. It eliminates the need for manual tool changes, saving time and improving production efficiency.

Tool Magazine

The tool magazine stores a variety of cutting tools available for use in the machining center. It facilitates quick tool changes, allowing for continuous operations and versatile machining capabilities.

Automatic Pallet Changer (APC) System

The automatic pallet changer (APC) system automates the loading and unloading of workpieces. It increases throughput, reduces downtime, and enhances the machining center’s overall efficiency.

Chip and Coolant Handling System

The chip and coolant handling system collects the chips generated during machining and provides coolant for efficient cooling and lubrication. It contributes to maintaining optimal cutting conditions and prolonging tool life.

Overload and Wear Detectors

Overload and wear detectors monitor tool wear and machine performance. They help in detecting signs of tool wear or performance degradation, allowing for timely maintenance to ensure consistent machining quality.

Automatic Door Operation Mechanism

The automatic door operation mechanism provides easy access to the work area. It enhances convenience and safety by allowing operators to load and unload workpieces efficiently.

The effective integration of these components in a machining center is crucial for achieving high precision, productivity, and quality in various machining operations.

What are the Main Axes of a Machining Center?

A machining center is equipped with multiple axes that enable precise movement and control during machining operations. Understanding the main axes of a machining center is crucial to achieve accurate cuts and intricate designs.

The main axes of a machining center include:

- X-axis: The X-axis controls the left and right movement of the cutting tool and workpiece. It is responsible for horizontal positioning.

- Y-axis: The Y-axis governs the forward and backward movement. It assists in vertical positioning and is crucial for creating depth in machining operations.

- Z-axis: The Z-axis manages the up and down movement, allowing for precise depth control during machining operations.

- A-axis: The A-axis controls the rotation around the X-axis and adds rotational capabilities to the machining center. It enables the creation of complex contours and shapes.

- B-axis: The B-axis handles the rotation around the Y-axis and complements the A-axis in achieving multi-axis machining capabilities. It provides additional flexibility for machining intricate features.

- C-axis: The C-axis is responsible for the rotation around the Z-axis. It enables rotational movements and adds versatility to machining operations.

By combining these axes, a machining center can achieve a wide range of movements and execute complex machining tasks with precision.

What are the Different Types of Machining Centers?

When it comes to machining centers, there are several types to choose from, each with its own unique features and capabilities. Let’s take a closer look at the different types of machining centers:

Horizontal Machining Centers (HMC)

Horizontal machining centers, also known as HMCs, have a horizontal spindle orientation. They are known for their rigidity, stability, and ability to handle heavy workpieces. HMCs are ideal for applications that require high precision and accuracy, such as aerospace and automotive industries. They are also commonly used for large-scale production.

Vertical Machining Centers (VMC)

Vertical machining centers, or VMCs, have a vertical spindle orientation. They are compact, versatile, and suitable for smaller spaces or individual users. VMCs are commonly used for small to medium-sized production runs and are highly efficient in milling, drilling, and other operations. They are widely used in industries such as electronics, medical, and general manufacturing.

Universal Machining Centers (UMC)

Universal machining centers, also known as UMCs, offer the best of both worlds. They can orient the spindle both horizontally and vertically, allowing for multi-sided machining and complex processes. UMCs are highly versatile and can handle a wide range of machining operations. They are often used in industries that require flexibility and precision, such as the aerospace and defense sectors.

Each type of machining center has its own advantages, and the choice depends on the specific needs and applications of the user. Whether it’s the rigidity of an HMC, the compactness of a VMC, or the versatility of a UMC, there’s a machining center to suit every machining requirement.

What are the Typical Operations Performed on a Machining Center?

A machining center is a versatile machine tool that can perform a variety of operations with precision and efficiency. Some of the typical operations performed on a machining center include:

- Milling: Milling involves removing material from the workpiece using rotary cutters. It is one of the most versatile machining operations and can be used to create complex shapes and profiles.

- Drilling: Drilling is the process of creating holes in the workpiece. Machining centers can accurately drill holes of different sizes and depths.

- Boring: Boring is the process of enlarging existing holes. Machining centers can perform precise boring operations to achieve the desired dimensions and tolerances.

- Threading: Threading is the process of creating internal or external threads on the workpiece. Machining centers can produce threads of various sizes and pitches.

These operations are essential in manufacturing various components and parts for industries such as automotive, aerospace, and general manufacturing. Machining centers offer high precision, automation, and efficiency, making them an indispensable tool in modern production facilities.

Machining Centre Applications

Machining centers are widely used in various industries, including automotive, aerospace, and general manufacturing. These versatile machines provide precision and efficiency, making them indispensable in modern manufacturing processes.

Automotive Industry

In the automotive industry, machining centers play a crucial role in the production of engine parts. They are used for grinding and drilling engine components, ensuring precise tolerances and surface finishes. Additionally, machining centers are utilized for creating dies for body components, such as door panels and bumpers. The ability to produce complex and accurate shapes makes machining centers essential in automotive manufacturing.

Aerospace Applications

Aerospace industry demands the highest level of precision and quality. Machining centers excel in meeting these requirements by machining complex shapes and components. They are used for manufacturing aerospace parts, such as turbine blades, engine components, and structural elements. Machining centers also prove invaluable in creating complex molds for aerospace industries, ensuring the integrity and intricacy of the final products.

General Manufacturing Industry

Machining centers find applications in the general manufacturing industry for producing a wide range of products used in daily life. From small electronic components to large industrial machinery parts, machining centers deliver accuracy and reliability. They are utilized in the production of consumer goods, industrial equipment, and various tools. The flexibility and versatility of machining centers make them indispensable in meeting the diverse manufacturing needs of different industries.

Throughout different industries, machining centers are transforming the manufacturing landscape by enabling high-quality production, reducing lead times, and improving overall efficiency.

How Much Does a Machining Center Cost?

The cost of a machining center can vary significantly depending on various factors, including the size, features, and capabilities of the machine. Generally, smaller, basic models of machining centers can be priced at a few thousand dollars. These entry-level machines are often suitable for smaller scale operations or businesses that have limited machining requirements.

On the other hand, larger, high-end machining centers with advanced features and capabilities can cost several hundred thousand dollars. These machines are typically designed for heavy-duty applications and can handle complex machining operations with precision and efficiency. They may also offer additional features such as multi-axis control and automation, which further enhance their performance.

When considering the cost of a machining center, it is crucial to evaluate the benefits and return on investment (ROI) that the machine can provide. Although the initial investment may seem significant, machining centers can greatly contribute to increased productivity, improved efficiency, and higher quality output. These advantages can lead to substantial cost savings and enhanced competitiveness in the long run.