If you’re new to CNC machining, you may have come across terms like turning, lathe, and mill-turn. But what exactly is the difference between them? In this article, we will delve into the distinctions between turning and lathe, providing you with the knowledge to make informed decisions for your machining projects.

When it comes to turning, the workpiece spins while the cutting tool removes material. On the other hand, a lathe machine is specifically designed for turning operations. It features a workpiece that spins at high speeds while a stationary cutting tool removes material.

But why is there a need for both turning and lathe? Well, it comes down to the complexity of the parts you want to machine. While turning is suitable for creating cylindrical parts or those with radial symmetry, a lathe machine can also perform drilling, boring, grooving, and threading operations.

Now that you have a basic understanding of turning and lathe, let’s explore mill-turn, another form of CNC machining. With mill-turn, you can combine milling and turning processes, allowing for the machining of more complex parts in a single setup.

So, whether you’re working on simple cylindrical parts or intricate components, understanding the differences between turning and lathe is key to selecting the right machining method for your project.

Understanding Milling

Milling is a fundamental process in CNC machining, widely used for its versatility and effectiveness in producing precise parts. In this section, we will explore the different types of milling, the machines involved, and the key aspects of CNC milling.

Types of Milling

There are various types of milling that cater to different machining needs:

- Vertical Milling: In vertical milling, the spindle and cutting tool are positioned above the workpiece. This configuration is ideal for operations that require plunging or drilling into the material.

- Horizontal Milling: Horizontal milling involves a horizontally-oriented spindle and cutting tool. It is commonly used for tasks that require heavy material removal or milling slots.

- CNC Milling: CNC milling refers to the process of milling using computer numerical control. It offers precise control and automation, allowing for high accuracy and repeatability.

Milling Machines

Milling machines are the backbone of the milling process. These machines can range from simple 2-axis machines to sophisticated multi-axis systems. They enable the rotation of the cutting tool while keeping the workpiece stationary or moving along a predetermined path.

Here is an overview of the key types of milling machines:

| Vertical Milling Machines | Horizontal Milling Machines |

|---|---|

| Position the spindle and cutter above the worktable | Orient the spindle horizontally |

| Well-suited for tasks that require plunging or drilling | Commonly used for heavy material removal and milling slots |

Vertical milling machines allow for greater flexibility in positioning the workpiece due to their vertical spindle arrangement. On the other hand, horizontal milling machines are excellent for tasks that demand high material removal rates or require intricate slotting.

It’s important to choose the right milling machine based on the specific requirements of your project, taking into account factors such as material type, part complexity, and desired precision.

Exploring Turning

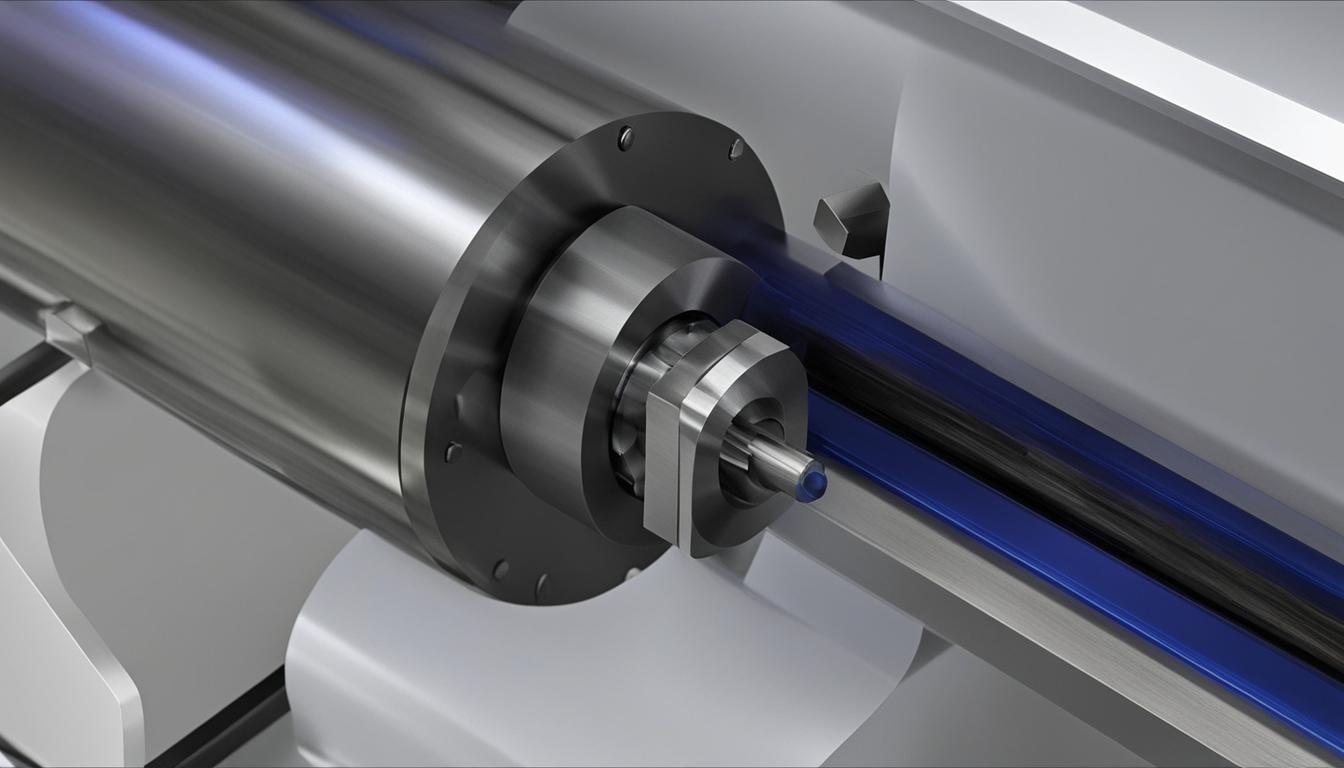

A lathe machine is a versatile tool designed for turning operations in the field of machining. By rotating the workpiece at high speeds, while a single-bladed cutting tool removes material, lathes are used to create cylindrical parts and parts with radial symmetry. The lathe’s configuration makes it ideal for working on oversized workpieces.

Turning is a fundamental machining process that enables the creation of cylindrical parts with precision and accuracy. The lathe machine can perform various turning operations, including drilling, boring, grooving, and threading. With the ability to shape materials such as metal, wood, and plastic, lathes are widely used across industries like automotive, aerospace, and manufacturing.

One of the key advantages of the lathe machine is its ability to achieve radial symmetry. This means that the resulting part will have a consistent shape around a central axis. This property is beneficial for applications that require uniformity and balance, such as components for engines or spindles for machinery.

Lathes are particularly useful for drilling operations, allowing precise holes to be made in the workpiece. Boring is another operation that lathes excel at, enabling the enlargement of existing holes. Threading is a process used to create threaded surfaces, essential for components that require the connection of various parts.

To better understand the capabilities of a lathe machine, here is a summary of the main operations it can perform:

- Turning: Shaping a cylindrical part by removing material from the workpiece.

- Drilling: Creating precise holes in the workpiece.

- Boring: Enlarging existing holes to achieve the desired size.

- Grooving: Making a narrow recess or groove on the surface of the workpiece.

- Threading: Creating threaded surfaces for the connection of parts.

| Operation | Description |

|---|---|

| Turning | Shaping a cylindrical part by removing material from the workpiece. |

| Drilling | Creating precise holes in the workpiece. |

| Boring | Enlarging existing holes to achieve the desired size. |

| Grooving | Making a narrow recess or groove on the surface of the workpiece. |

| Threading | Creating threaded surfaces for the connection of parts. |

Unveiling the Mill-Turn Process

The mill-turn process is a cutting-edge hybrid technique that combines milling and turning operations into a single setup. By integrating both milling and turning functionalities, mill-turn machines offer a highly efficient and time-saving solution for machining complex parts without the need for switching between different machining centers.

Mill-turn machines are specifically designed to handle the challenges of machining intricate and multifaceted components. With the ability to perform both milling and turning operations in one setup, these machines provide increased precision, accuracy, and versatility, making them ideal for industries that require the production of complex parts.

One of the primary advantages of the mill-turn process is its ability to handle a wide range of operations, such as drilling, boring, threading, and grooving, in addition to milling and turning. This comprehensive range of machining capabilities enables manufacturers to streamline their production process and eliminate the need for multiple machines.

Furthermore, the integration of milling and turning operations in a single setup eliminates the need for repositioning the workpiece, resulting in improved accuracy and reduced setup time. This seamless combination of operations allows for higher precision and efficiency, leading to increased productivity and cost savings.

Mill-turn machines are widely used in various industries that require precision machining of complex parts, such as aerospace, automotive, and medical industries. These machines offer the ability to handle intricate geometries, challenging materials, and tight tolerances, making them the go-to solution for demanding machining applications.

To provide a better understanding of the benefits of the mill-turn process, below is a table comparing the capabilities and advantages of mill-turn machines:

| Advantages of Mill-Turn Machines | Capabilities |

|---|---|

| Simultaneous milling and turning operations | Perform milling, turning, drilling, boring, threading, and grooving |

| Efficient handling of complex parts | Machining of intricate geometries and multifaceted components |

| Improved accuracy and reduced setup time | Elimination of workpiece repositioning |

| Increased productivity and cost savings | Streamlined production process and elimination of multiple machines |

The table highlights the key advantages and capabilities of mill-turn machines, showcasing their ability to revolutionize the machining process for complex parts.

With their exceptional capabilities and versatility, mill-turn machines have become indispensable tools for manufacturers seeking to produce complex parts with utmost precision and efficiency. The integration of milling and turning operations in a single setup empowers industries to meet the increasingly demanding requirements of modern manufacturing.

The Evolution of Lathes into Turning Centers

Turning centers have revolutionized the capabilities of traditional lathes, taking them to new heights of precision and versatility. While lathes are typically 2-axis machines designed for turning operations, turning centers have evolved to include advanced multi-axis capabilities, making them the preferred choice for complex machining tasks.

One significant advantage of turning centers is their ability to perform operations beyond traditional turning. With 3-axis, 4-axis, and even 5-axis configurations, turning centers can integrate milling, drilling, and sub-spindle capabilities, enabling the machining of intricate parts in a single setup.

Horizontal turning centers are the most commonly used type. These machines feature a horizontal spindle orientation and allow for efficient chip evacuation. They are widely utilized in various industries, including automotive, aerospace, and manufacturing.

On the other hand, vertical turning centers offer enhanced capabilities for machining larger workpieces. With their vertical chuck orientation and the tool turret approaching from the side, vertical turning centers provide excellent stability and precision for heavy-duty applications.

Advantages of Turning Centers:

- Multi-axis capabilities for increased precision and flexibility

- Integration of milling, drilling, and sub-spindle capabilities

- Efficient chip evacuation in horizontal turning centers

- Stability and precision for machining larger workpieces in vertical turning centers

In summary, turning centers have evolved from traditional lathes to offer enhanced capabilities for complex machining tasks. With their multi-axis configurations, integration of additional operations, and different orientations, turning centers provide a versatile solution for a wide range of industries.

Operations in Turning Centers

Turning centers offer a wide range of operations beyond traditional lathes. They can perform multi-axis turning, allowing for cutting around corners and inside cuts. Turning centers excel in various operations, including:

- Drilling: Turning centers can efficiently perform drilling operations, creating precise holes in the workpiece.

- Boring: With the capability to rotate and move the cutting tool simultaneously, turning centers can effectively perform boring operations, enlarging existing holes and achieving high accuracy.

- Reaming: Turning centers are equipped to execute reaming operations, refining the surface and size of pre-drilled holes.

- Knurling: By applying controlled pressure and rotational movement, turning centers can create knurled patterns on the workpiece, improving grip and aesthetics.

- Taper Cutting: Turning centers with more than two axes can perform taper cutting operations, producing conical shapes with precision.

- Threading: With specialized tooling and precise control, turning centers can efficiently create internal and external threads on the workpiece.

- Facing: Turning centers excel in facing operations, ensuring a clean and smooth edge to the workpiece while trimming it to the precise length.

These operations in turning centers allow for enhanced versatility and efficiency in manufacturing processes, making them suitable for a wide range of applications and industries.

Multiaxis Turning

One of the key advantages of turning centers is their ability to perform multiaxis turning. With the flexibility of multiple controlled axes, they can execute complex cutting paths and achieve intricate shapes, even around corners and inside cuts. This capability expands the design possibilities and allows for the creation of more intricate and efficient parts.

Additionally, turning centers offer enhanced precision and repeatability, ensuring consistent and accurate results across multiple batches or projects.

The image above visually represents the range of operations that can be performed in turning centers, showcasing the versatility and capabilities of these advanced machining systems.

Comparing CNC Lathe and CNC Turning Center

When it comes to turning operations, both CNC lathes and CNC turning centers are viable options. However, CNC turning centers offer several additional features that make them stand out in terms of automation, precision, and efficiency.

One of the key advantages of CNC turning centers is automated tool changing. These machines can automatically swap out tools, saving time and reducing the need for manual intervention. This feature allows for greater flexibility and versatility in machining operations.

Another notable feature of CNC turning centers is the inclusion of live rotating tools. Unlike traditional lathes, these machines are equipped with tools that can rotate and perform milling, drilling, and other operations while the workpiece is spinning. This capability expands the range of tasks that can be accomplished in a single setup.

Efficient chip removal is also a significant advantage offered by CNC turning centers. The machines are designed to handle chip evacuation effectively, minimizing the risk of chip build-up and ensuring uninterrupted machining processes.

While CNC turning centers offer these additional features, they can be more complex to operate compared to CNC lathes. However, the benefits of increased automation and precision outweigh the learning curve associated with their operation.

CNC lathes, on the other hand, are better suited for short production runs, simple parts, and quick repairs. Their straightforward design and operation make them ideal for these types of tasks.

To summarize, CNC turning centers excel in high-volume production and material removal, thanks to features such as automated tool changing, live rotating tools, and efficient chip removal. CNC lathes, although less automated, are better suited for short production runs and simpler parts.

CNC Lathe vs. CNC Turning Center: A Comparison

| Features | CNC Lathe | CNC Turning Center |

|---|---|---|

| Tool Changing | Manual | Automated |

| Live Tools | N/A | Available |

| Chip Removal | Standard | Efficient |

| Complexity | Low | Higher |

| Production Runs | Short | High-volume |

While both machines have their strengths, the choice between a CNC lathe and a CNC turning center depends on the specific requirements of the project, including the desired production volume, part complexity, and level of automation.

Horizontal vs Vertical Turning Centers

When considering turning centers for your machining needs, one important factor to consider is the orientation of the spindle. Horizontal turning centers feature a horizontally oriented spindle, with the tools approaching from above the rotating part. This setup allows for efficient chip clearance as gravity aids in pulling the chips away from the workpiece.

On the other hand, vertical turning centers, also known as vertical turret lathes (VTL), have the spindle set flat on the ground. This orientation enables the machining of larger pieces at lower RPMs. The tool turret or carriage approaches the workpiece from the side, providing versatility for different machining operations.

The choice between horizontal and vertical turning centers depends on various factors, including the application, part size, and required machining capabilities. Horizontal turning centers excel in chip clearance, making them well-suited for applications with a high volume of chip production. Vertical turning centers, on the other hand, are ideal for machining large, heavy workpieces and offer the advantage of lower RPMs for improved stability and precision.

Ultimately, the decision should be based on the specific requirements of your machining project, taking into account the size and complexity of the parts, the desired machining capabilities, and the efficiency of chip clearance.

Comparison of Horizontal and Vertical Turning Centers

| Features | Horizontal Turning Centers | Vertical Turning Centers |

|---|---|---|

| Spindle Orientation | Horizontal | Vertical |

| Approach of Tools | Above the rotating part | From the side |

| Chip Clearance | Efficient, aided by gravity | Dependent on workpiece size and tool configuration |

| Machining Capabilities | Well-suited for high-volume chip production | Ideal for machining large, heavy workpieces at lower RPMs |

Choosing the Right Machine for Your Project

When undertaking a CNC machining project, selecting the appropriate machine is crucial to ensure efficient production and desirable outcomes. The choice often boils down to whether a CNC lathe or a CNC turning center is the better fit for your specific requirements.

CNC Lathes: CNC lathes are the go-to option for short production runs, prototyping, and simpler parts. These machines offer manual controllability and flexibility, allowing operators to make adjustments and fine-tune the machining process as needed. CNC lathes are ideal for projects where precision and adaptability are essential.

CNC Turning Centers: On the other hand, CNC turning centers are better suited for high-volume production and material removal tasks. With automated tool changing and live tooling capabilities, turning centers enable seamless transitions between different machining operations, resulting in higher production rates and increased efficiency. These machines excel in projects that require a substantial amount of material removal and demand maximum productivity.

Determining the right machine for your project depends on factors such as desired production rate, complexity of the parts, and the specific requirements of your manufacturing process. Carefully consider these aspects and assess the trade-offs between manual control and automation, flexibility, and production volume before making your selection.

Key Considerations:

- Production volume: CNC lathes are suitable for short runs and prototyping, while turning centers are more efficient for high-volume production.

- Complexity of parts: CNC lathes excel in producing simpler parts, while turning centers are better equipped to handle more intricate designs.

- Automation: Turning centers offer automated tool changing and live tooling capabilities, streamlining the production process and reducing the need for manual interventions.

- Material removal: If your project involves substantial material removal, a turning center’s increased power and higher production rates may be advantageous.

By carefully evaluating your project requirements and considering the factors mentioned above, you can make an informed decision when selecting between a CNC lathe and a CNC turning center. Keep in mind that some projects may require a combination of both machines, depending on the specific needs of different parts or production stages.

Ultimately, the machine selection process is critical to achieving optimal results and meeting production targets. Whether you prioritize flexibility, precision, or volume production, choosing the right machine is an essential step towards successful CNC machining.

Finding Your CNC Machine

When it comes to finding the right CNC machine for your manufacturing needs, exploring the inventory of used equipment can be a cost-effective solution. CNC machines are versatile and can be programmed to suit a variety of applications. By purchasing used equipment, you can save costs without compromising on the quality of the machine.

Companies like Precise Tool and Manufacturing Inc. and Southern Fabricating Machinery Sales offer a wide range of CNC machines for sale. Their extensive inventory includes CNC lathes, turning centers, milling machines, and more. With their expertise and industry knowledge, they can assist you in finding the perfect machine to meet your specific requirements.

Whether you are looking for a CNC machine for prototyping or high-volume production, exploring the options available in the used equipment market can provide you with a range of choices. From small-scale operations to large manufacturing facilities, investing in a reliable CNC machine from trusted sellers can enhance your productivity and efficiency in the long run.